Filter compensation device of monocrystalline silicon furnace power supply

A technology of compensation device and silicon furnace, applied in the direction of harmonic reduction device, reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems of reduced reliability, mechanical noise, long production cycle, etc., and achieve the goal of manufacturing The effect of improving the efficiency of installation, reducing the time of downtime, and reducing the loss of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

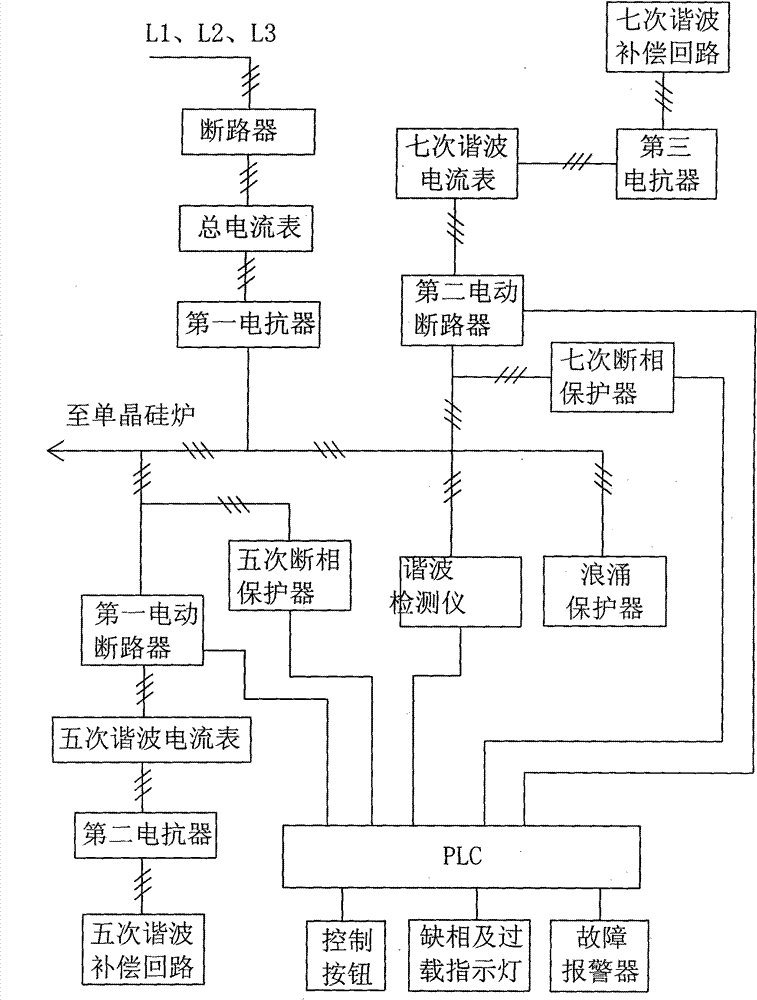

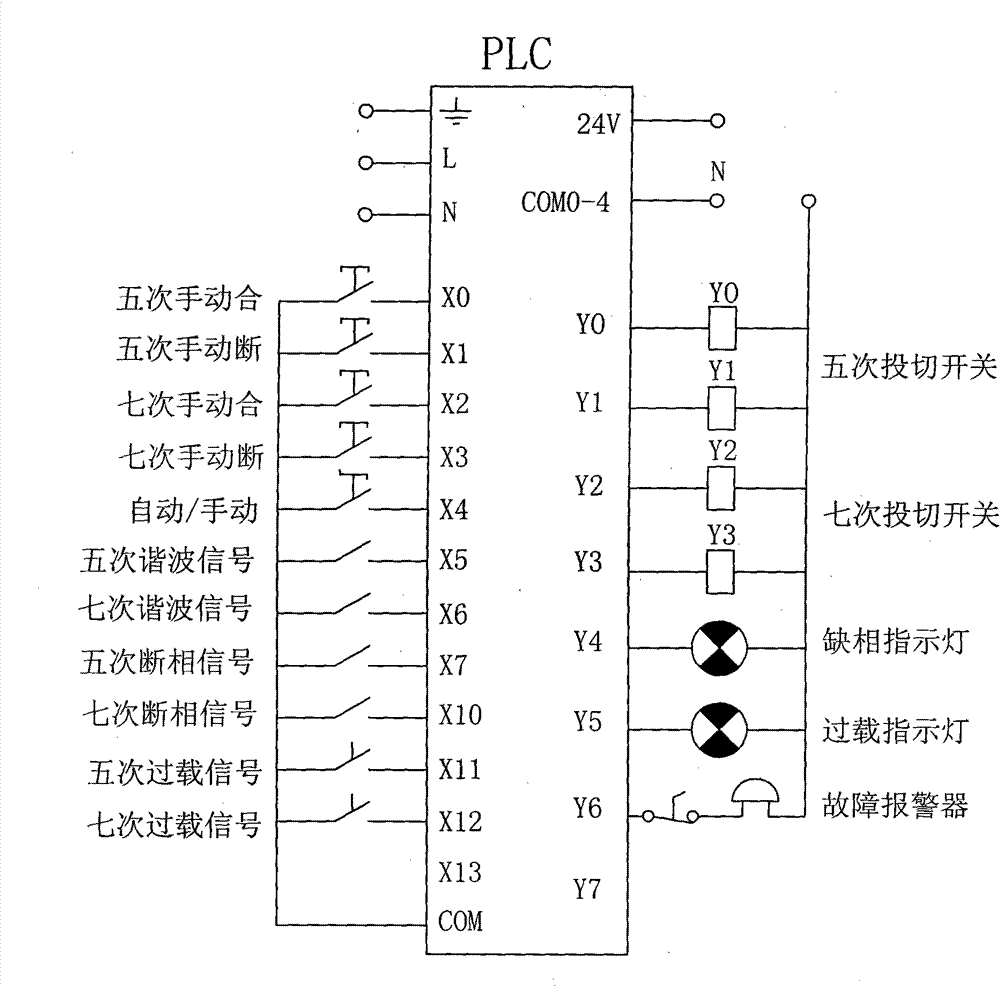

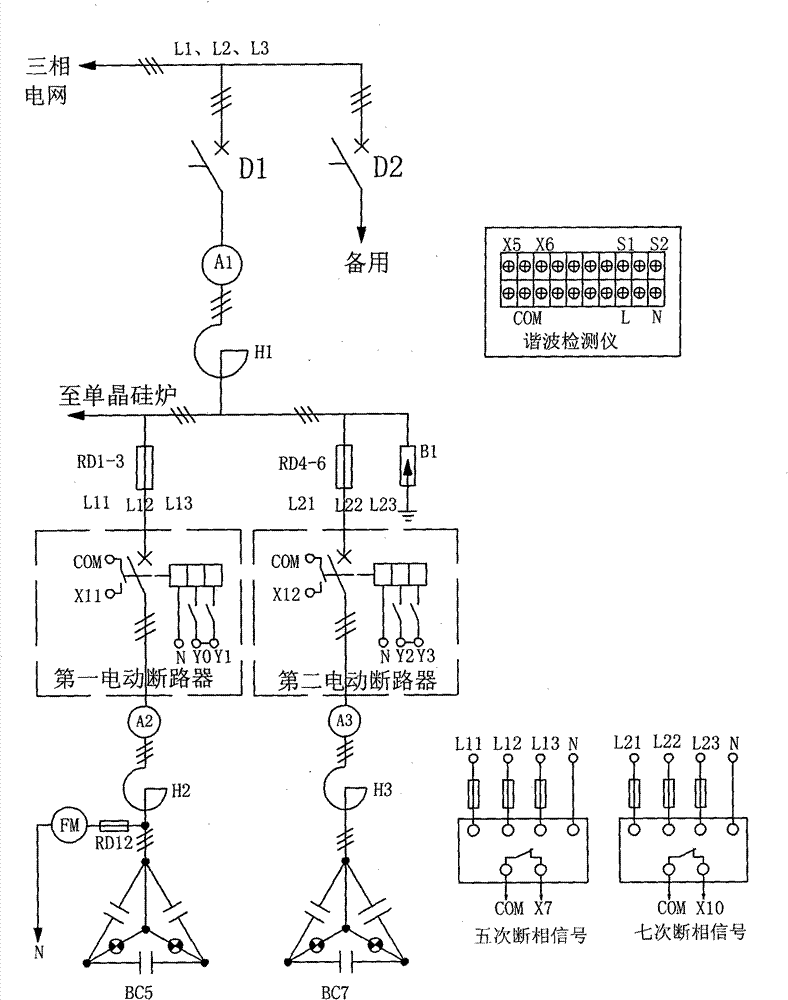

[0018] like Figure 1-3 , the monocrystalline silicon furnace power supply filter compensation device of this embodiment includes: figure 1 or L1, L2, L3 in 3) connected to the circuit breaker D1, and the first reactor H1 connected to the power supply output end of the circuit breaker D1; the current output end of the first reactor H1 is connected to the first motorized circuit breaker, the second The second electric circuit breaker, the fifth phase failure protector, the seventh phase failure protector are connected to the power supply terminal of the harmonic detector, the fifth phase failure signal output terminal of the fifth phase failure protector, and the seventh phase failure protector The seventh phase failure signal output terminal, the fifth and seventh harmonic signal output terminals of the harmonic detector are connected to the PLC; the current ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com