Direct current step-up/step-down circuit

A technology of buck-boost circuit and DC bus, which is applied in the direction of circuit devices, battery circuit devices, collectors, etc., can solve the problems of reduced system equalization effect, low power transfer efficiency, and many times of power conversion, so as to improve energy transfer efficiency , Convenient system maintenance, eliminate the effect of conduction pressure drop loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

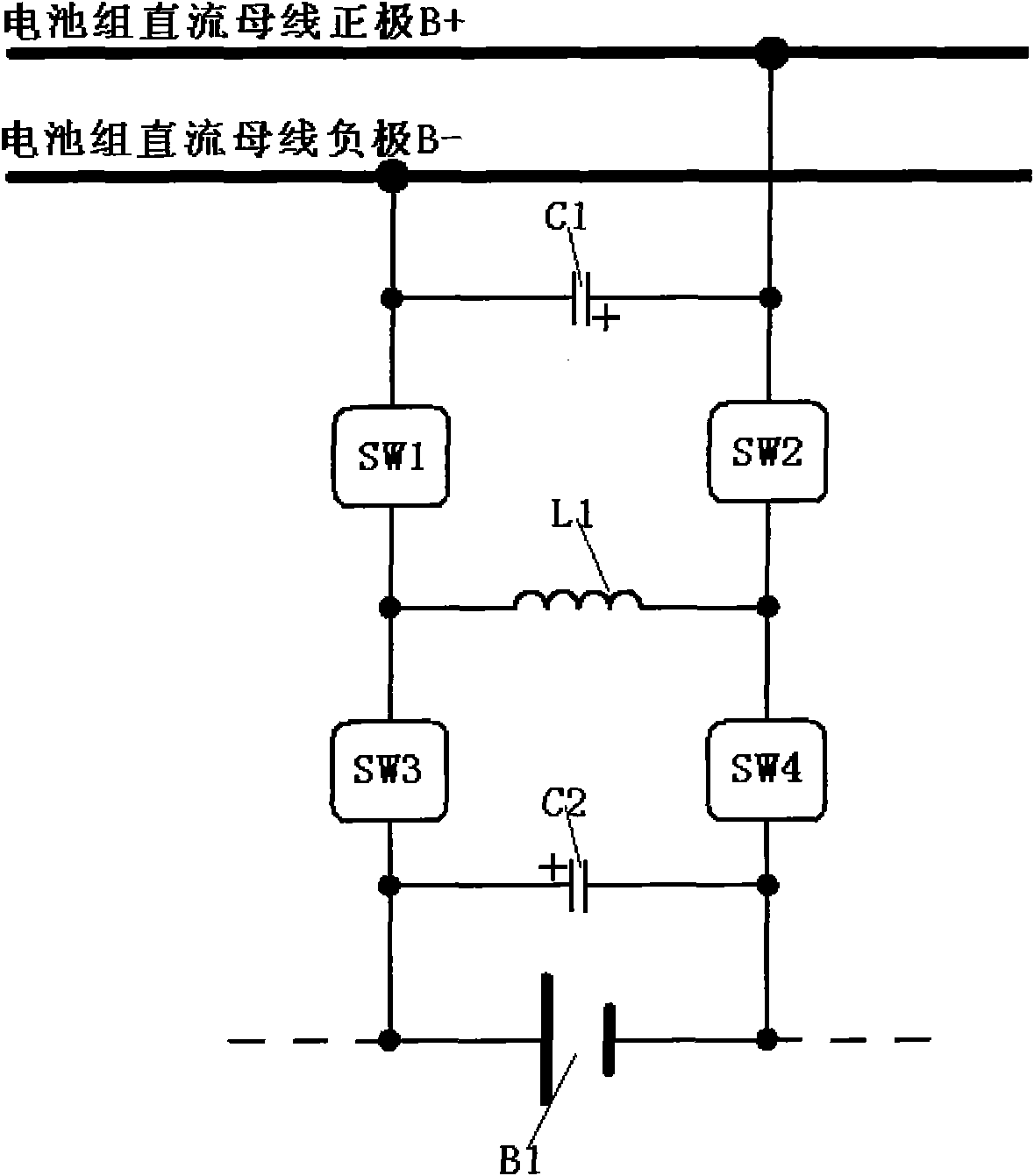

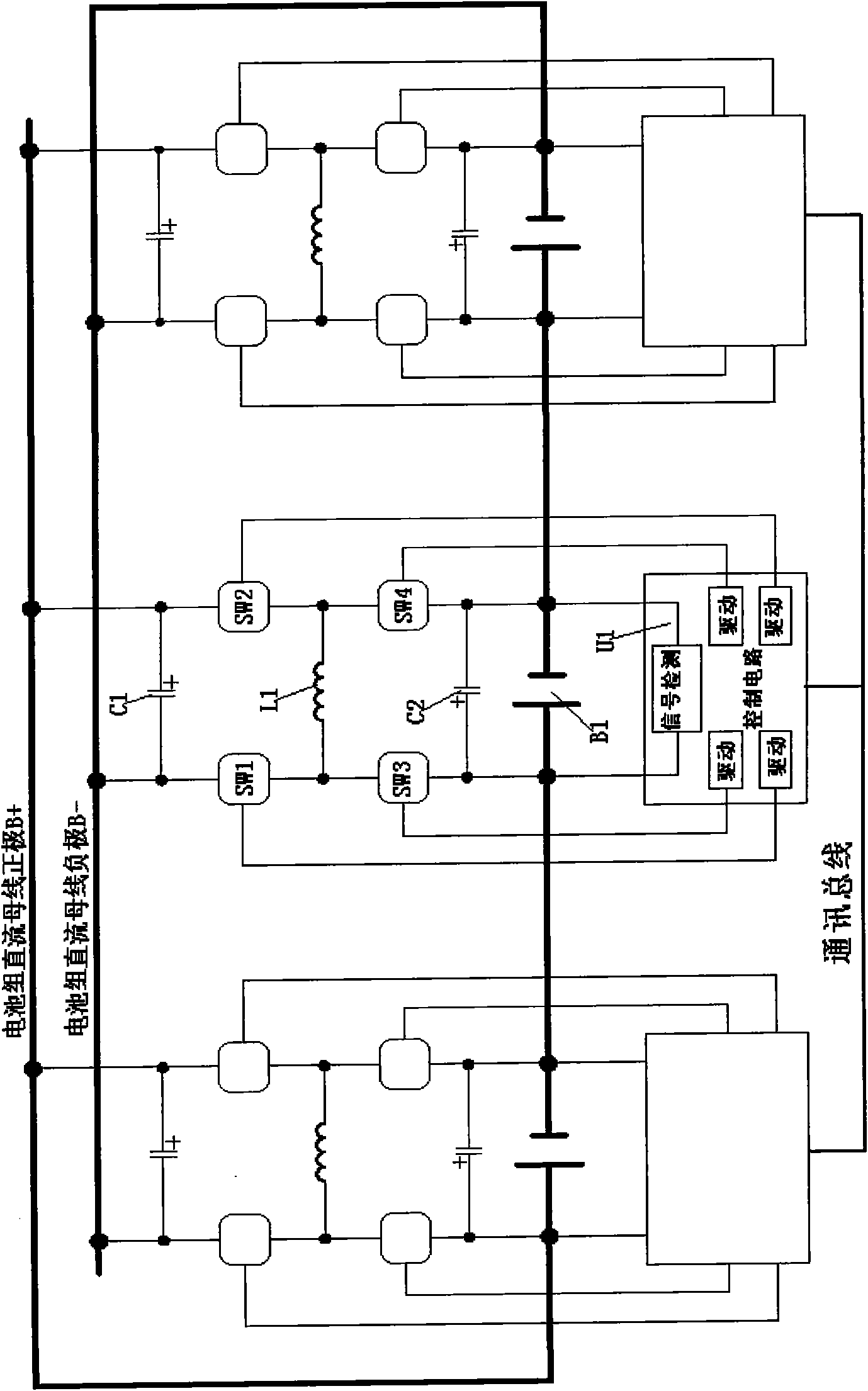

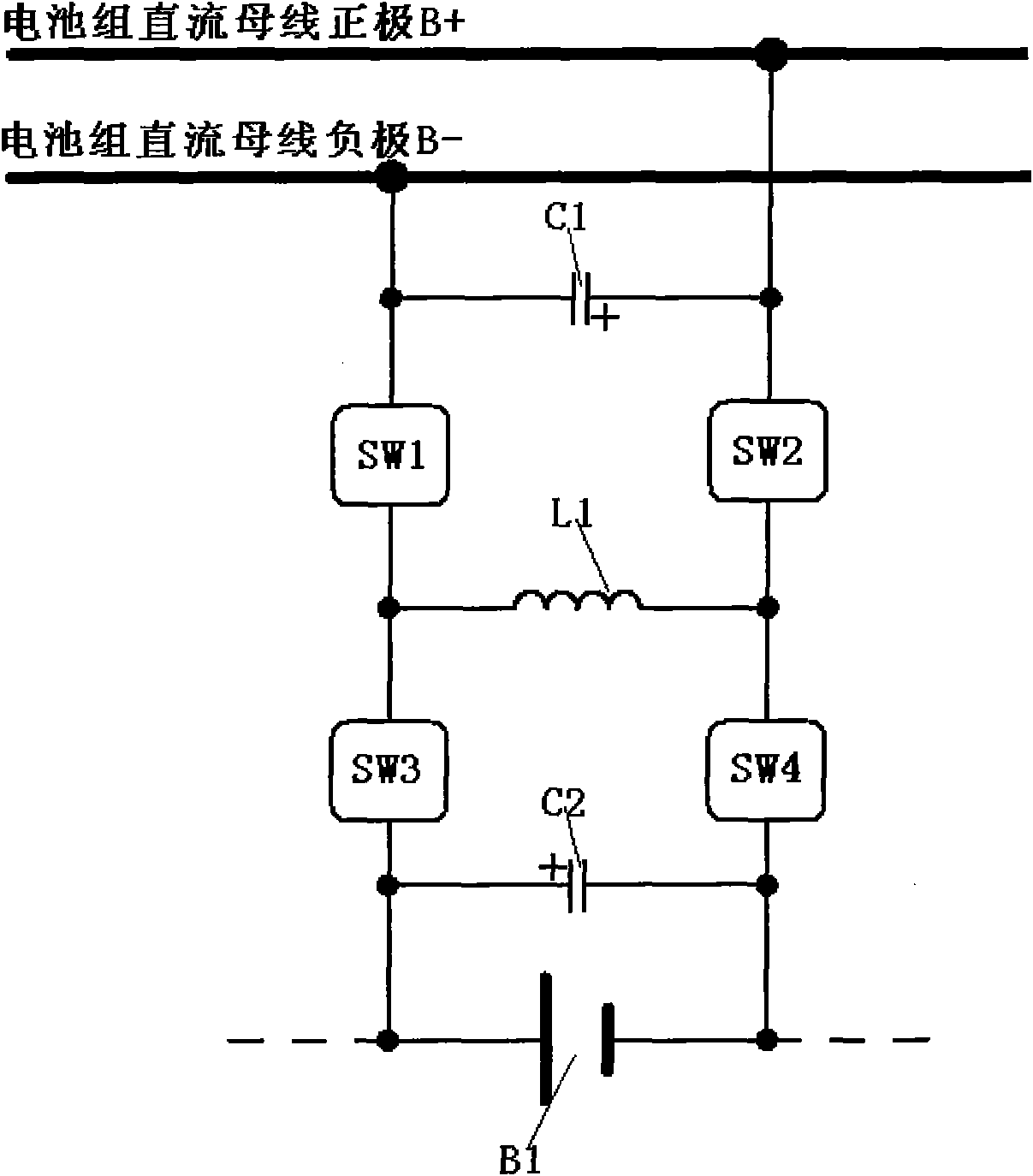

[0020] figure 1 It is a block diagram of the principle of the present invention. A DC buck-boost circuit is shown in the figure, including the DC bus bar of the battery pack, battery cells and switching devices, characterized in that: the positive pole of the battery cell B1 is connected to one end of the third switching device SW3, and the other end of the third switching device SW3 is connected to the storage One end of the energy storage inductor L1 and one end of the first switching device SW1, the other end of the energy storage inductor L1 is connected to one end of the second switching device SW2 and one end of the fourth switching device SW4, and the other end of the fourth switching device SW4 is connected to the battery Negative terminal of unit B1. The other end of the first switching device SW1 is connected to the negative pole of the DC bus bar of the battery pack, and the other end of the second switching device SW2 is connected to the positive pole of the DC bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com