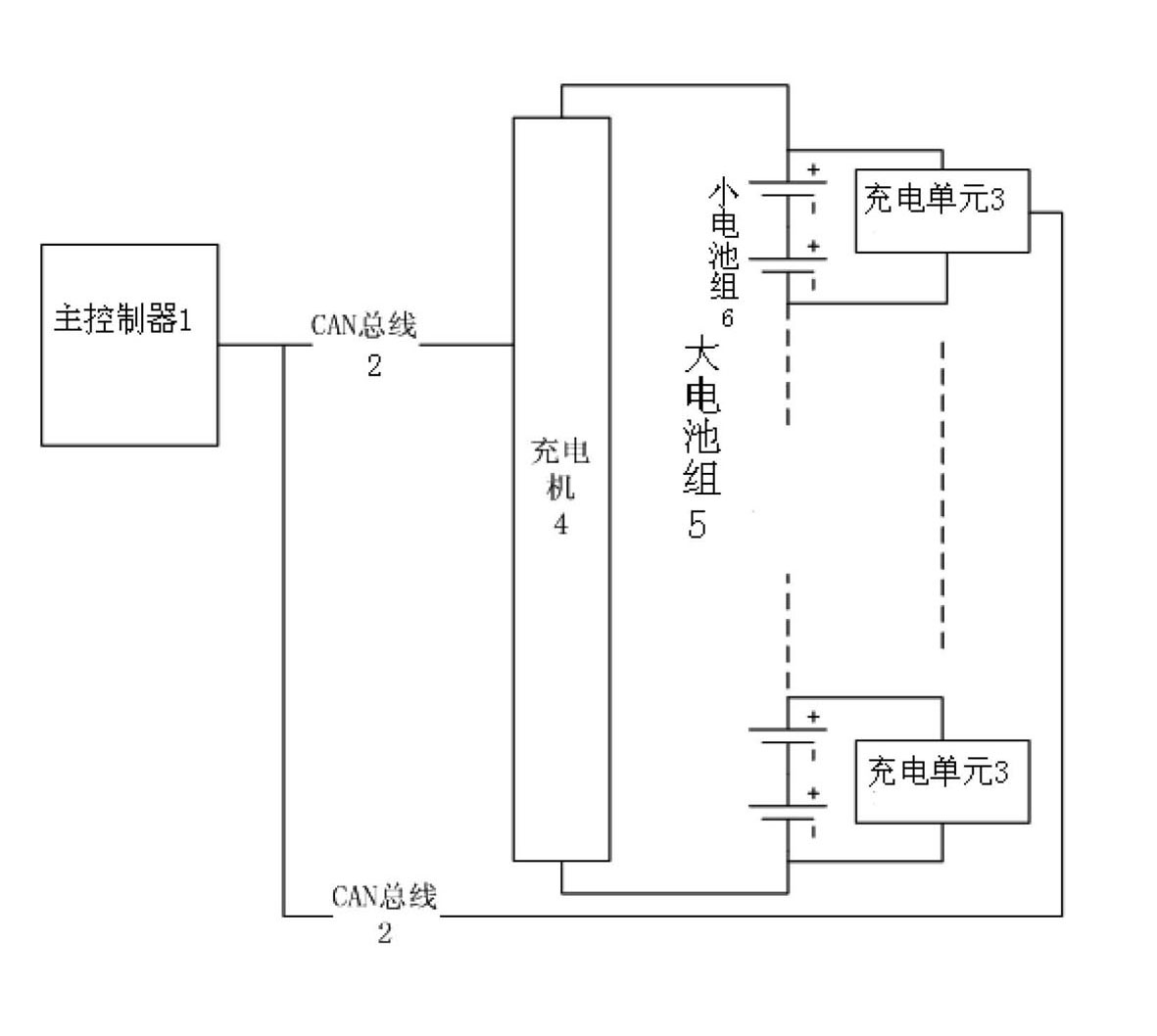

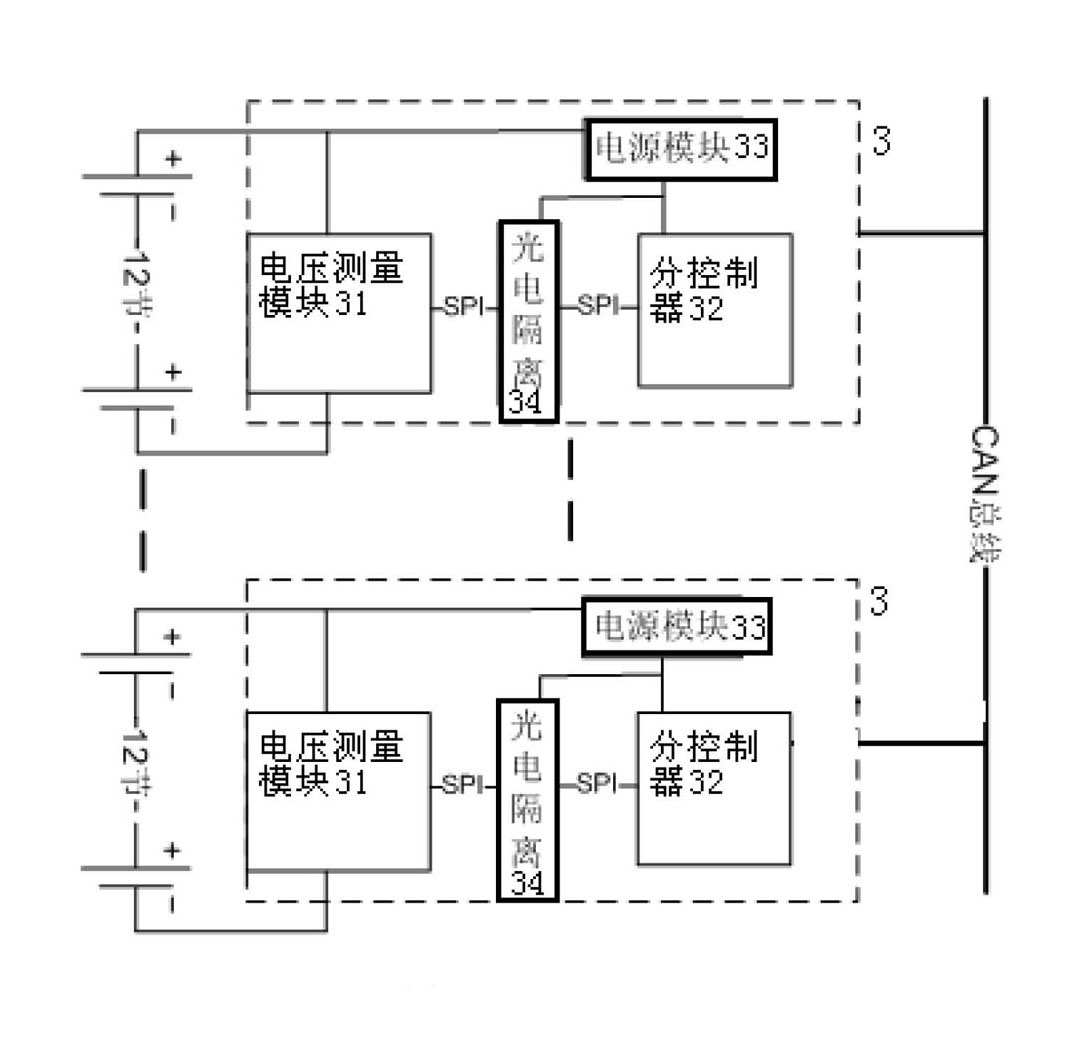

Constant power charging system and method of lithium battery pack

A technology of constant power charging and lithium battery pack, which is applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of long charging time, unsuitable for fast charging of large-capacity batteries, and short time for the maximum power of the charger. Achieve the effect of improving charging efficiency, saving charging time and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

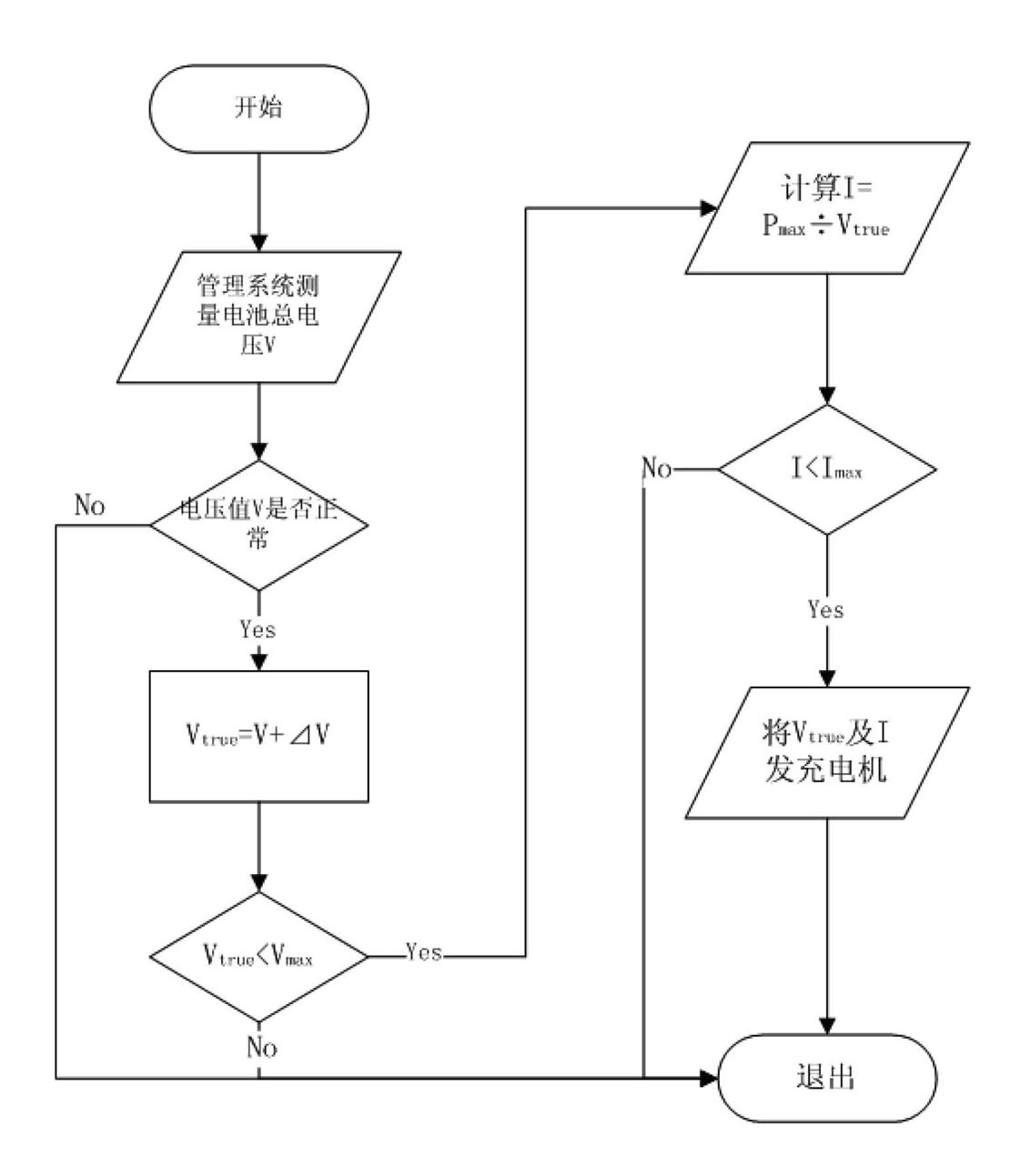

[0056] The large battery pack 5 consists of 96 lithium batteries connected in series, each cell has a capacity of 100Ah and a nominal voltage of 355V for charging the lithium manganate battery pack. The initial voltage of the large battery pack 5 is

[0057]

[0058] The charge termination voltage is

[0059]

[0060] According to the characteristics of the lithium iron manganate battery, at a charging rate of 0.2C, using the conventional constant current and constant voltage charging method, the ratio R of the battery capacity charged in the constant current charging stage to the total battery capacity is about 85%.

[0061] (1) In the constant current and constant voltage charging mode, the output parameters of the charger are 403V and 20A, and the maximum power of the charger = , then the time required for the constant current phase is

[0062]

[0063] The constant current charging process takes 4.25 hours. According to the characteristics of the lithium...

Embodiment 2

[0071] The large battery pack 5 is charged by a lithium iron phosphate battery pack with a capacity of 100Ah and a nominal voltage of 360V with 120 batteries connected in series. The initial voltage of the large battery pack 5 is

[0072]

[0073] The charge termination voltage is

[0074]

[0075] According to the characteristics of the lithium iron manganate battery, at a charging rate of 0.2C, using the conventional constant current and constant voltage charging method, the ratio R of the battery capacity charged in the constant current charging stage to the total battery capacity is about 90%.

[0076] (1) In the constant current and constant voltage charging mode, the output parameters of the charger are 444V and 20A, and the maximum power of the charger = , then the time required for the constant current phase is

[0077]

[0078] The constant current charging process takes 4.5 hours. According to the characteristics of the lithium iron phosphate batte...

Embodiment 3

[0086] The large battery pack 5 consists of 120 cells connected in series, each cell has a capacity of 100Ah, and a nominal voltage of 360V is charged by a lithium iron phosphate battery pack. The initial voltage of the battery pack is

[0087]

[0088] The charge termination voltage is

[0089]

[0090] According to the characteristics of the lithium iron manganate battery, at a charging rate of 1C, the conventional constant current and constant voltage charging method is adopted, and the ratio R of the battery capacity charged in the constant current charging stage to the total battery capacity is about 70%.

[0091] (1) In the constant current and constant voltage charging mode, the output parameters of the charger are 444V and 100A, and the maximum power of the charger = , then the time required for the constant current phase is

[0092]

[0093] The constant current charging process takes 42 minutes. According to the characteristics of the lithium iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com