Cylindrical thermoelectric generator

A technology of thermoelectric generator and thermoelectric power generation, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems of uneven temperature at the cold end of thermoelectric power generation components, uncertain specific positions of heat collectors, and unstable power generation, etc., to achieve structural Compactness, improved shock resistance, enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

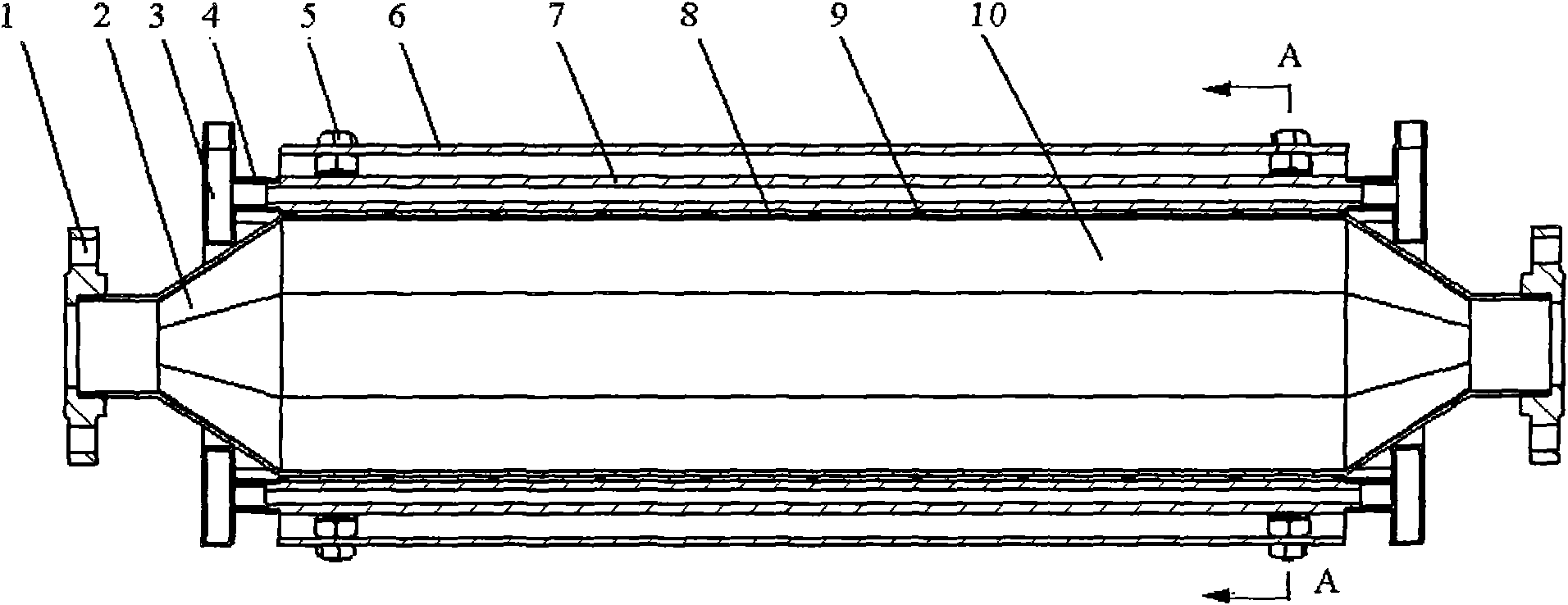

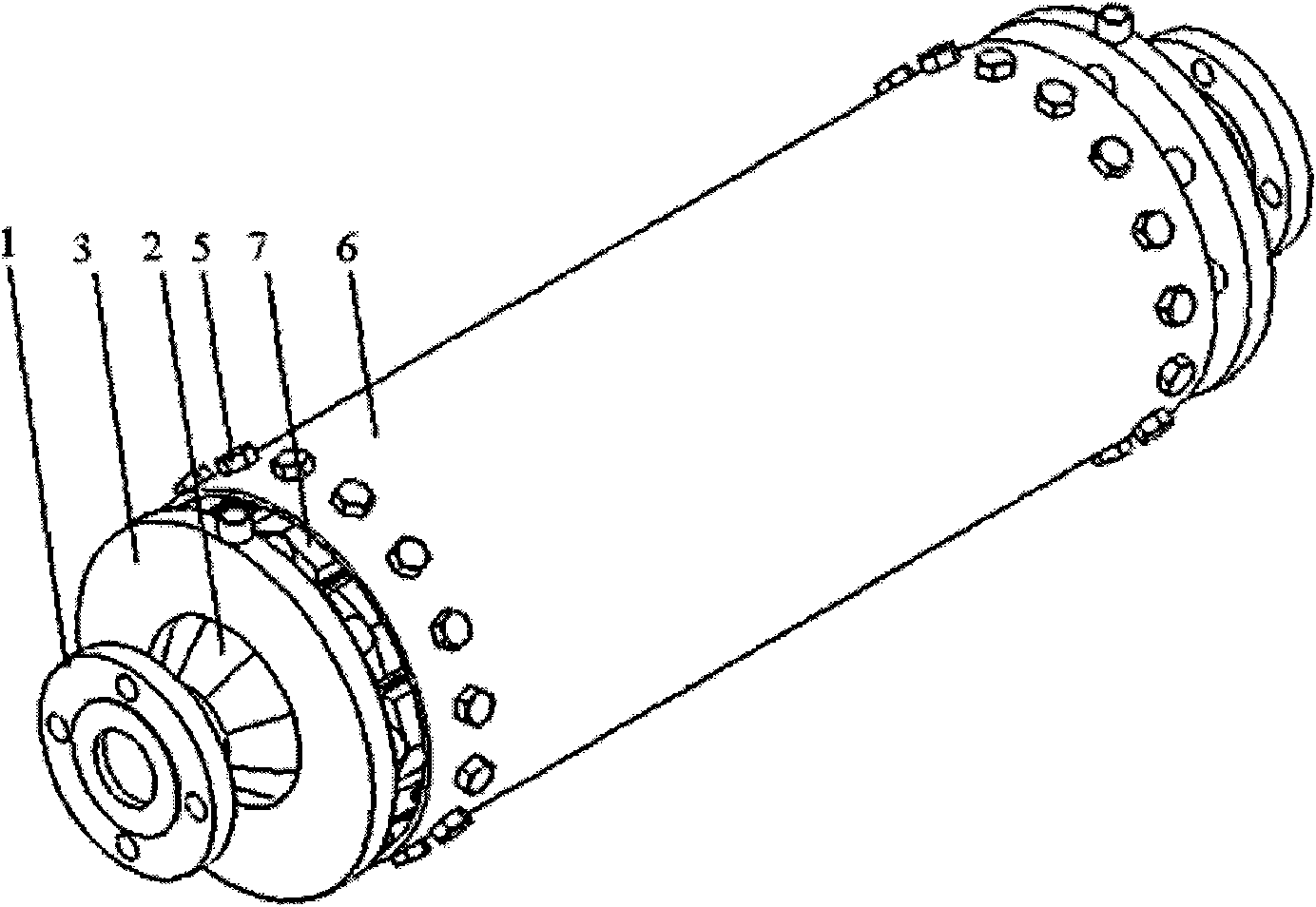

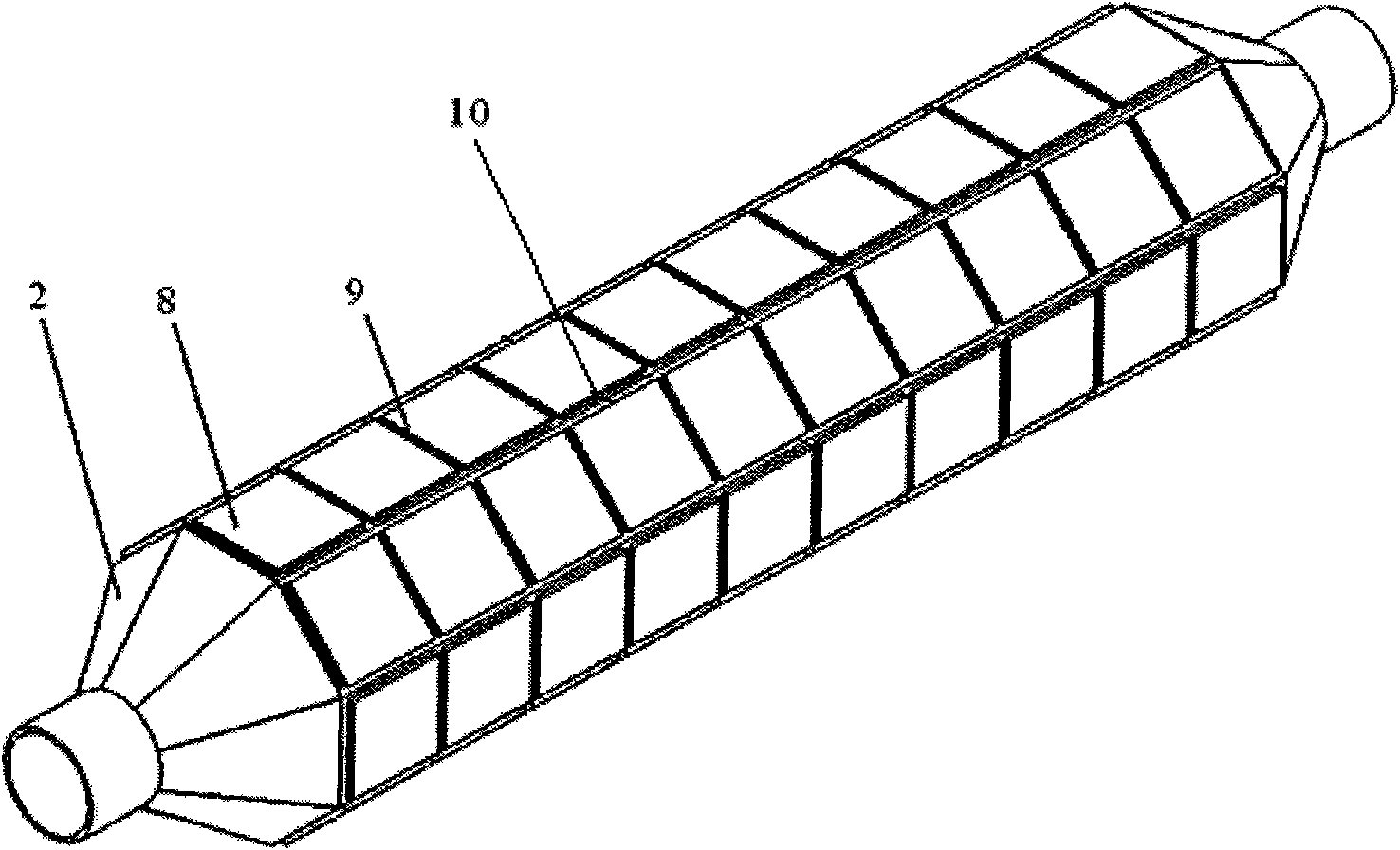

[0036] like figure 1 and figure 2 As shown, a cylindrical thermoelectric generator includes an octagonal exhaust pipe, a sleeve 6, a thermoelectric power generation assembly 8, an insulating layer 9, a cooling fin 7, and a cooling water jacket 3. The octagonal exhaust pipe Divided into two end parts 2 and a main part 10, the sleeve 6 and the octagonal exhaust pipe are coaxially sleeved on the outermost side of the octagonal exhaust pipe main part 10; the octagonal exhaust pipe main part Each side of 10 is arranged with a thermoelectric power generation assembly 8 and a thermal insulation layer 9, and the thermal insulation layer 9 is arranged between each thermoelectric power generation assembly 8; It is connected to the heat sink 7; the heat sink 7, the thermoelectric power generation component 8, and the heat insulation layer 9 are all symmetrically distributed on the main part 10 of the octagonal exhaust pipe along the center of the octagonal exhaust pipe; the cooling wat...

Embodiment 2

[0054] Present embodiment except following feature other structures are with embodiment 1: as Figure 7 As shown, the number of thermoelectric power generation assemblies 8 on each side of the octagonal exhaust pipe is five.

[0055] The series connection groups on the side of the octagonal exhaust pipe are connected in parallel.

[0056] The material of the thermal insulation layer is ceramic wool.

Embodiment 3

[0058] Present embodiment except following feature other structures are with embodiment 1: as Figure 8 As shown, the number of thermoelectric power generation assemblies 8 on each side of the octagonal exhaust pipe is 15.

[0059] The heat insulating layer material is glass wool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com