Vibrating ladle slag carry-over detection-oriented embedded data acquisition system

A technology of data acquisition system and signal acquisition system, which is applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc. It can solve the problems of high difficulty in preprocessing and transmission, achieve low power consumption and ensure reliable work High performance and real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

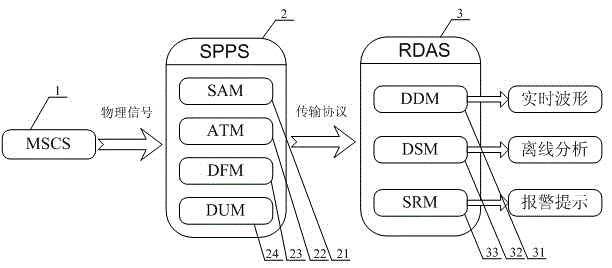

[0043] refer to Figure 1-3 , an embedded data acquisition system for vibrating ladle slag detection, including multi-channel signal collection system (Multi-channel Signal Collection System, MSCS) 1, signal preprocessing system (Signal Preprocessing System, SPPS) 2 and real-time Data Analysis System (Real-time Data Analysis System, RDAS)3;

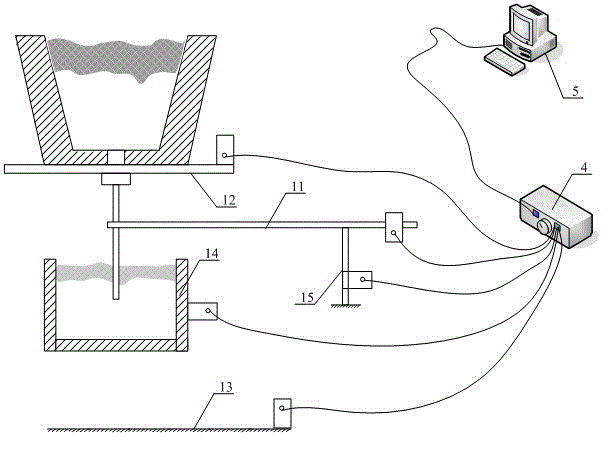

[0044] The multi-point parallel signal acquisition system 1 takes the ladle pouring mechanism and its supporting platform as the investigation object, determines a plurality of characteristic vibration signal measurement points, and then installs a vibration sensor at each measurement point to comprehensively collect the ladle pouring process. The shock vibration signal generated is initially amplified and processed, and finally the signal is sent to the signal preprocessing system 2 in parallel;

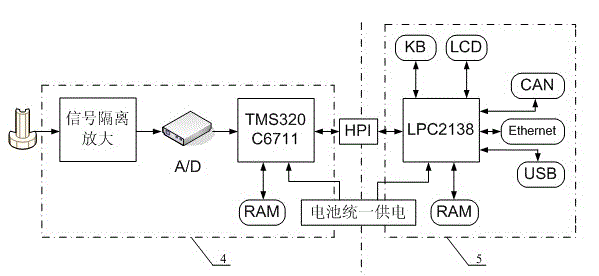

[0045] Described signal preprocessing system 2 can receive the real-time vibration signal of multi-channel sensor, uploads to real-time data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com