Poly(nonamethyleneterephthalamide) material and preparation method thereof

A technology of polynonanediamine terephthalamide and nonanediamine phthaloyl, which is applied in the field of high-performance and low-cost modified and reinforced polynonanediamine terephthalamide materials and its preparation, and can solve the problem of poor fluidity , processing difficulties and other problems, to achieve the effect of improving fluidity, simple preparation process and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

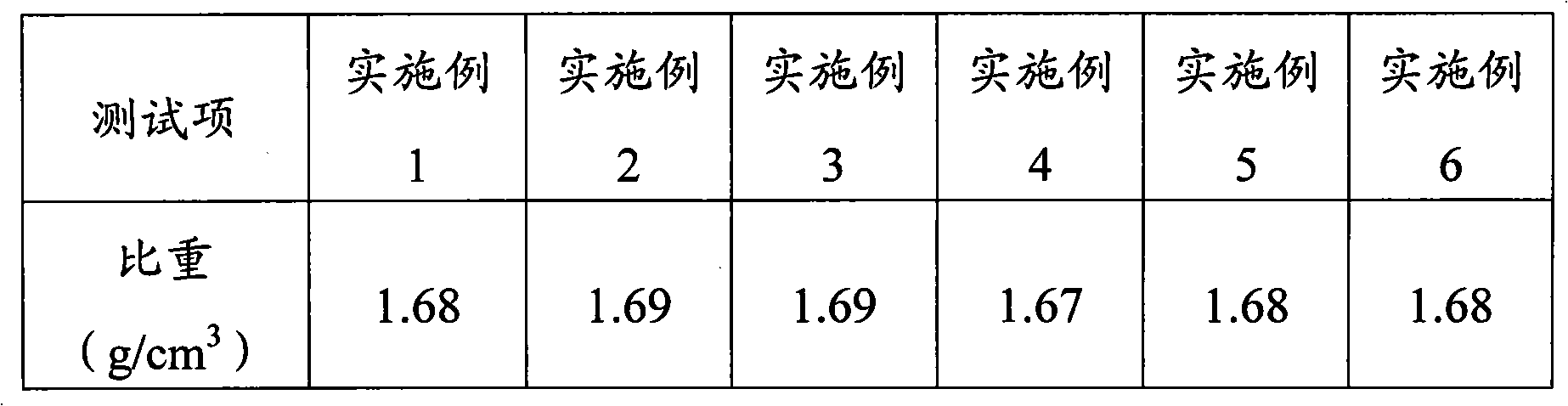

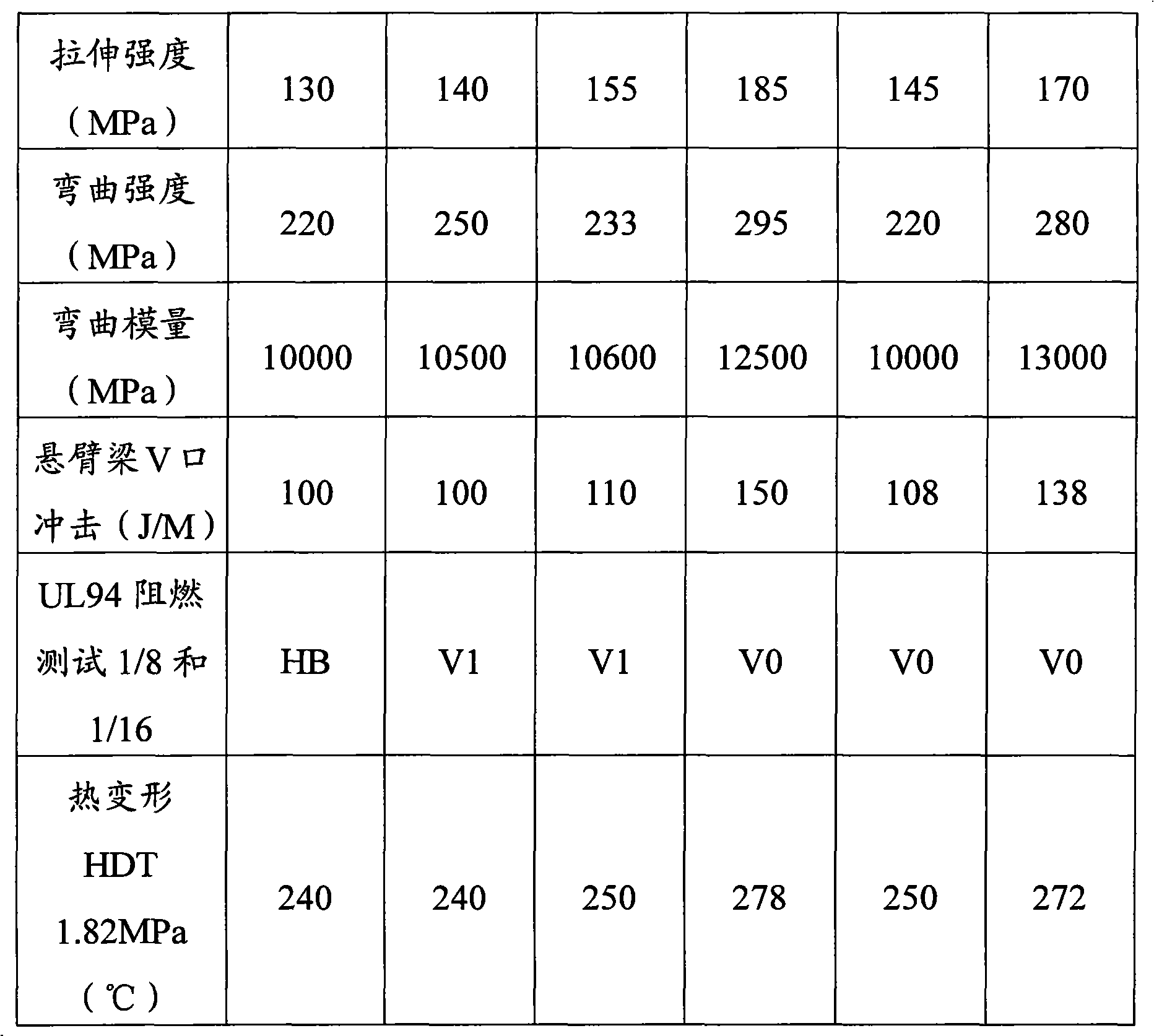

Embodiment 1

[0040] Weigh 40 parts of polynonanediamine terephthalamide (PA9T), 20 parts of polyamide (PA66), 10 parts of main flame retardant PBS-701010 parts, auxiliary flame retardant Sb 2 o 3 4 parts, 40 parts of long glass fiber 988A, 0.3 parts of antioxidants 1010 and 168, 0.3 parts of lubricant TAF and siloxane, 0.3 parts of nucleating agent CAV1020. Preparation of PA9T flame retardant reinforced material.

[0041] Composite materials were prepared by the following methods:

[0042] a. Weigh raw materials, including polynonanediamine terephthalamide (100°C for 3h), polyamide (90°C for 4h), and dry the raw materials respectively;

[0043] b. Add the dry polynonanediamine terephthalamide and polyamide into the high-speed mixer, and add lubricant, nucleating agent and antioxidant, and mix at high speed for about 4 minutes;

[0044] c. Put the main flame retardant and auxiliary flame retardant into the high-speed mixer and mix for about 8 minutes. After mixing, add the mixed flame re...

Embodiment 2

[0048] Weigh 35 parts of polynonanediamine terephthalamide (PA9T), 10 parts of polyamide (PA66), 11.5 parts of main flame retardant PBS-7010, auxiliary flame retardant Sb 2 o 3 3.5 parts, 40 parts of long glass fiber 988A, 0.3 parts of antioxidants 1010 and 168, 0.3 parts of lubricant TAF and siloxane, and 0.3 parts of nucleating agent CAV1020. Preparation of PA9T flame retardant reinforced material.

[0049] Composite materials were prepared by the following methods:

[0050] a. Weigh raw materials, including polynonanediamine terephthalamide (120°C for 3h), polyamide (95°C for 4h), and dry the raw materials respectively;

[0051] b. Add the dry polynonanediamine terephthalamide and polyamide into the high-speed mixer, and add lubricant, nucleating agent and antioxidant, and mix at high speed for about 4 minutes;

[0052] c. Put the main flame retardant and auxiliary flame retardant into the high-speed mixer and mix for about 7 minutes. After mixing, add the mixed flame re...

Embodiment 3

[0057] Weigh 34 parts of polynonanediamine terephthalamide (PA9T), 9.5 parts of polyamide (PA66), 11.5 parts of main flame retardant PBS-7010, and auxiliary flame retardant Sb 2 o 3 3.5 parts, long glass fiber T635B 40 parts, antioxidant 1010 and 168 are 0.3 parts, lubricant TAF and siloxane are 0.3 parts, nucleating agent CAV1020.3 parts. Preparation of PA9T flame retardant reinforced material.

[0058] Composite materials were prepared by the following methods:

[0059] a. Weighing raw materials, including polynonanediamine terephthalamide (110°C for 3h) and polyamide (100°C for 4h), and drying the raw materials respectively;

[0060] b. Add the dried polynonanediamine terephthalamide and polyamide into the high-speed mixer, and add lubricant, nucleating agent and antioxidant, and mix at high speed for about 5 minutes;

[0061] c. Put the main flame retardant and auxiliary flame retardant into the high-speed mixer and mix for about 4 minutes. After mixing, add the mixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com