Non-fluorescent graphitic lubricant for drilling fluid

A graphite lubricant, non-fluorescence technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of drilling fluid viscosity, increased shear force, difficult to meet, difficult to biodegrade, etc., to prevent pressure difference Drill sticking, prolonging service life, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A non-fluorescent graphite lubricant for drilling fluids, the lubricant is made of the following ingredients by weight percentage:

[0025] Solid graphite 70%

[0026] Polyoxyethylene ether 30%

[0027] The method for preparing non-fluorescent graphite lubricant comprises the following steps:

[0028] ① Add the solid graphite of the above formula into the pulverizer, and process it into a certain 120-mesh graphite fine powder;

[0029] ②Put graphite fine powder into a container with a mixer, add polyoxyethylene ether in the amount of the above formula while stirring, and make it fully mixed;

[0030] ③Package after natural air drying or drying.

Embodiment 2

[0032] A non-fluorescent graphite lubricant for drilling fluids, the lubricant is made of the following ingredients by weight percentage:

[0033] Solid graphite 80%

[0034] Polyoxyethylene ether 20%

[0035] The method for preparing non-fluorescent graphite lubricant comprises the following steps:

[0036] ① Add the solid graphite of the above formula into the pulverizer, and process it into a certain 120-mesh graphite fine powder;

[0037] ②Put graphite fine powder into a container with a mixer, add polyoxyethylene ether in the amount of the above formula while stirring, and make it fully mixed;

[0038] ③Package after natural air drying or drying.

Embodiment 3

[0040] A non-fluorescent graphite lubricant for drilling fluids, the lubricant is made of the following ingredients by weight percentage:

[0041] Solid graphite 90%

[0042] Polyoxyethylene Ether 10%

[0043] The method for preparing non-fluorescent graphite lubricant comprises the following steps:

[0044] ① Add the solid graphite of the above formula into the pulverizer, and process it into a certain 120-mesh graphite fine powder;

[0045] ②Put graphite fine powder into a container with a mixer, add polyoxyethylene ether in the amount of the above formula while stirring, and make it fully mixed;

[0046] ③Package after natural air drying or drying.

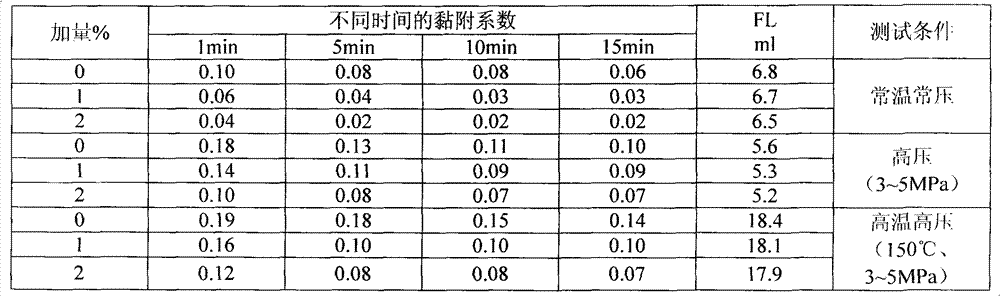

[0047] Add the present invention in 6% bentonite slurry, measure its lubricating coefficient, the result is as table 4:

[0048] Table 4 Lubrication performance of the present invention

[0049] Invention (1%)

[0050] As can be drawn from Table 4, the present invention has excellent lubricity, and when the addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com