Shale plugging inhibitor for shale gas horizontal well drilling and preparation method thereof

A technology for horizontal wells and inhibitors, which is applied in wellbore/well components, chemical instruments and methods, earthwork drilling and production, etc. It can solve the problem that the rheological properties of high molecular weight polymers are greatly affected, and the temperature resistance of treatment agents needs to be improved. The problems such as the inability of the agent to be effectively blocked, etc., to achieve the effects of easy control, mild reaction conditions, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

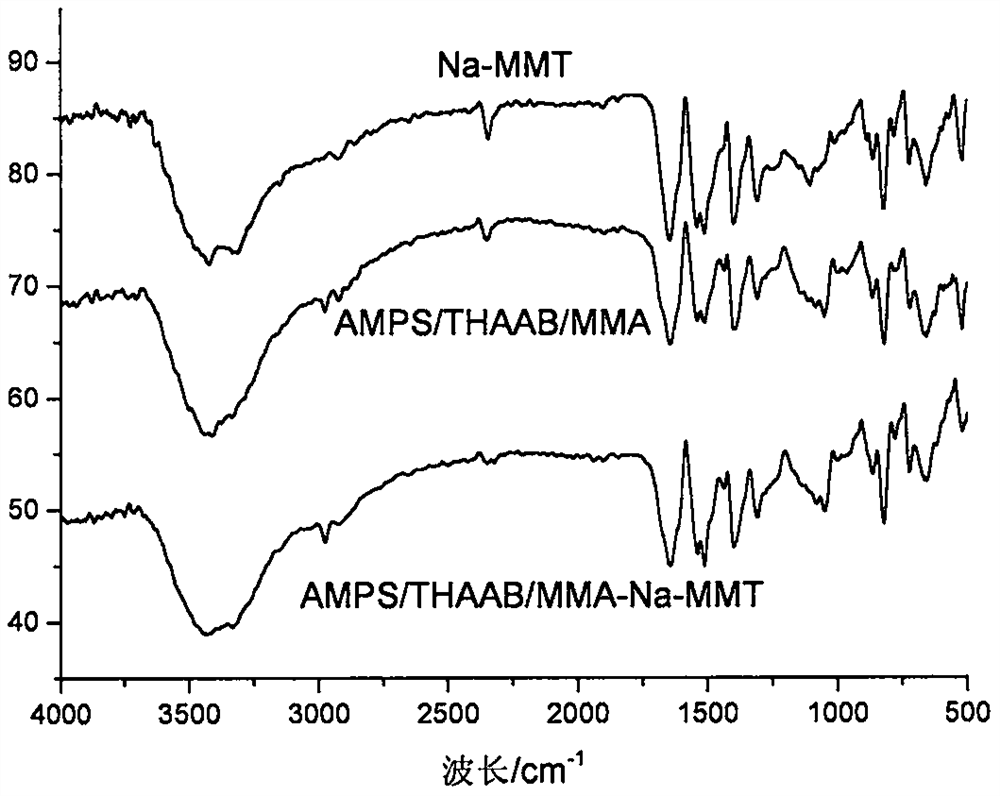

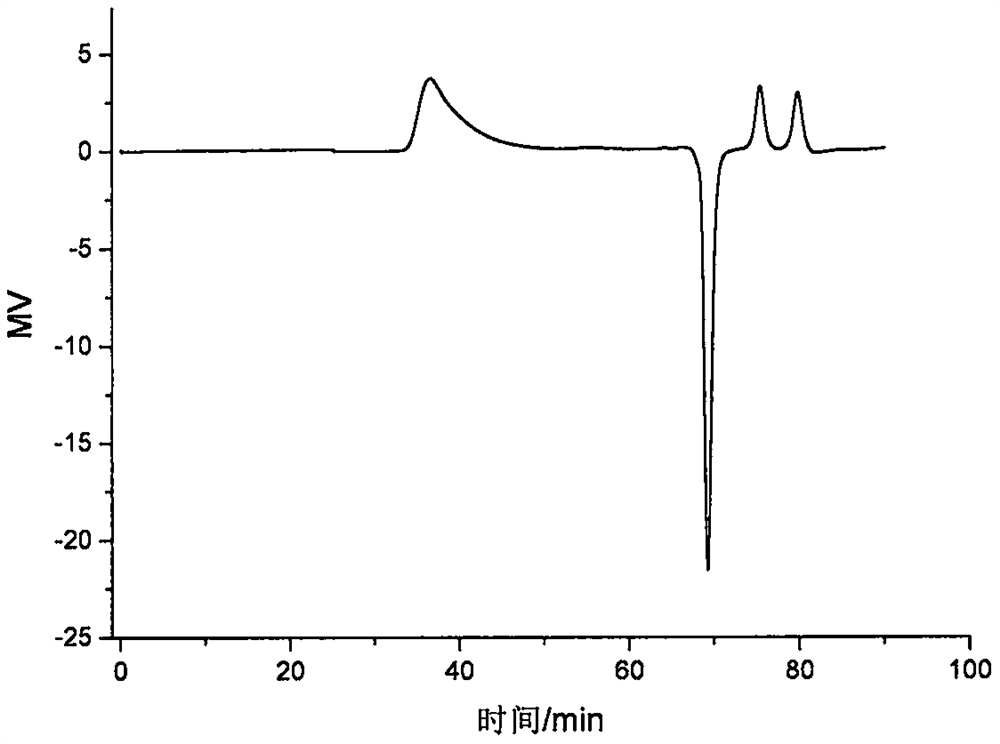

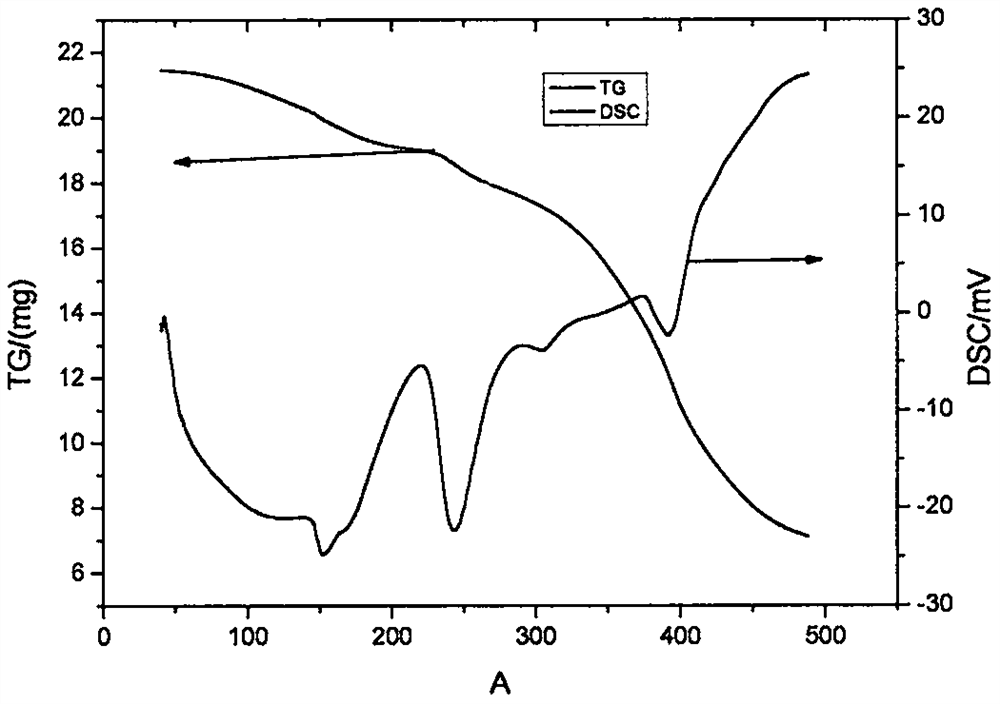

[0030] S1. Synthesis of new low molecular weight polymer AMPS / THAAB / MMA: Accurately control the total monomer concentration of 45wt%, weigh 0.1g of AMPS dissolved in deionized water and place it in a three-necked flask, pass nitrogen and oxygen for 10 minutes; add in sequence 0.2g THAAB, drop 0.7g MMA and 0.015g chain transfer agent and seal immediately; quickly sprinkle 0.025g of K 2 S 2 o 8 and NaHSO 3 and sealed. After the mixed solution was polymerized at 70° C. for 1 hour, a viscous product was obtained. After the product was fully washed with absolute ethanol and sheared and granulated, it was placed in a vacuum oven for a certain period of time to obtain 0.94 g of new low molecular weight AMPS / THAAB / MMA, with a number average molecular weight Mn of 34152 and a weight average molecular weight Mw of 42153.

[0031] S2. A preparation of shale plugging inhibitor for shale gas horizontal well drilling: the shale inhibitor is composed of novel low molecular weight AMPS / TH...

Embodiment 2

[0033] S1. Synthesis of new low-molecular-weight polymer AMPS / THAAB / MMA: Accurately control the total monomer concentration of 45wt%, weigh 0.2g of AMPS dissolved in deionized water and place it in a three-necked flask, pass nitrogen and oxygen for 10 minutes; add in sequence 0.3g THAAB, drop 0.5g MMA and 0.025g chain transfer agent and seal immediately; quickly sprinkle 0.030g of K 2S 2 o 8 and NaHSO 3 and sealed. After the mixed solution was polymerized at 80° C. for 1.5 hours, a viscous product was obtained. After the product was fully washed with absolute ethanol and sheared and granulated, it was placed in a vacuum oven for a certain period of time to obtain 0.96 g of new low molecular weight AMPS / THAAB / MMA, with a number average molecular weight Mn of 34695 and a weight average molecular weight Mw of 41668.

[0034] S2. A preparation of shale plugging inhibitor for shale gas horizontal well drilling: the shale inhibitor is composed of novel low molecular weight AMPS / ...

Embodiment 3

[0036] S1. Synthesis of new low-molecular-weight polymer AMPS / THAAB / MMA: Accurately control the total monomer concentration of 45wt%, weigh 0.25g of AMPS dissolved in deionized water and place it in a three-necked flask, pass nitrogen and oxygen for 10min; 0.35g THAAB, drop 0.4g MMA and 0.030g chain transfer agent and seal immediately; quickly sprinkle 0.035g K 2 S 2 o 8 and NaHSO 3 and sealed. After the mixed solution was polymerized at 90° C. for 1.5 hours, a viscous product was obtained. After the product was fully washed with absolute ethanol and sheared and granulated, it was placed in a vacuum oven for a certain period of time to obtain 0.93 g of new low molecular weight AMPS / THAAB / MMA, with a number average molecular weight Mn of 35698 and a weight average molecular weight Mw of 41726.

[0037] S2. A preparation of shale plugging inhibitor for shale gas horizontal well drilling: the shale inhibitor is composed of novel low molecular weight AMPS / THAAB / MMA, oil phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com