Intake connecting pipe for diesel engine

A technology of intake pipe and intake pipe, which is applied in the direction of fuel air intake, mechanical equipment, engine components, etc., can solve the problems of uncompact structure, small front warehouse space, affecting EGR rate, etc., so as to avoid wall collision effect, Reasonable structural layout and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

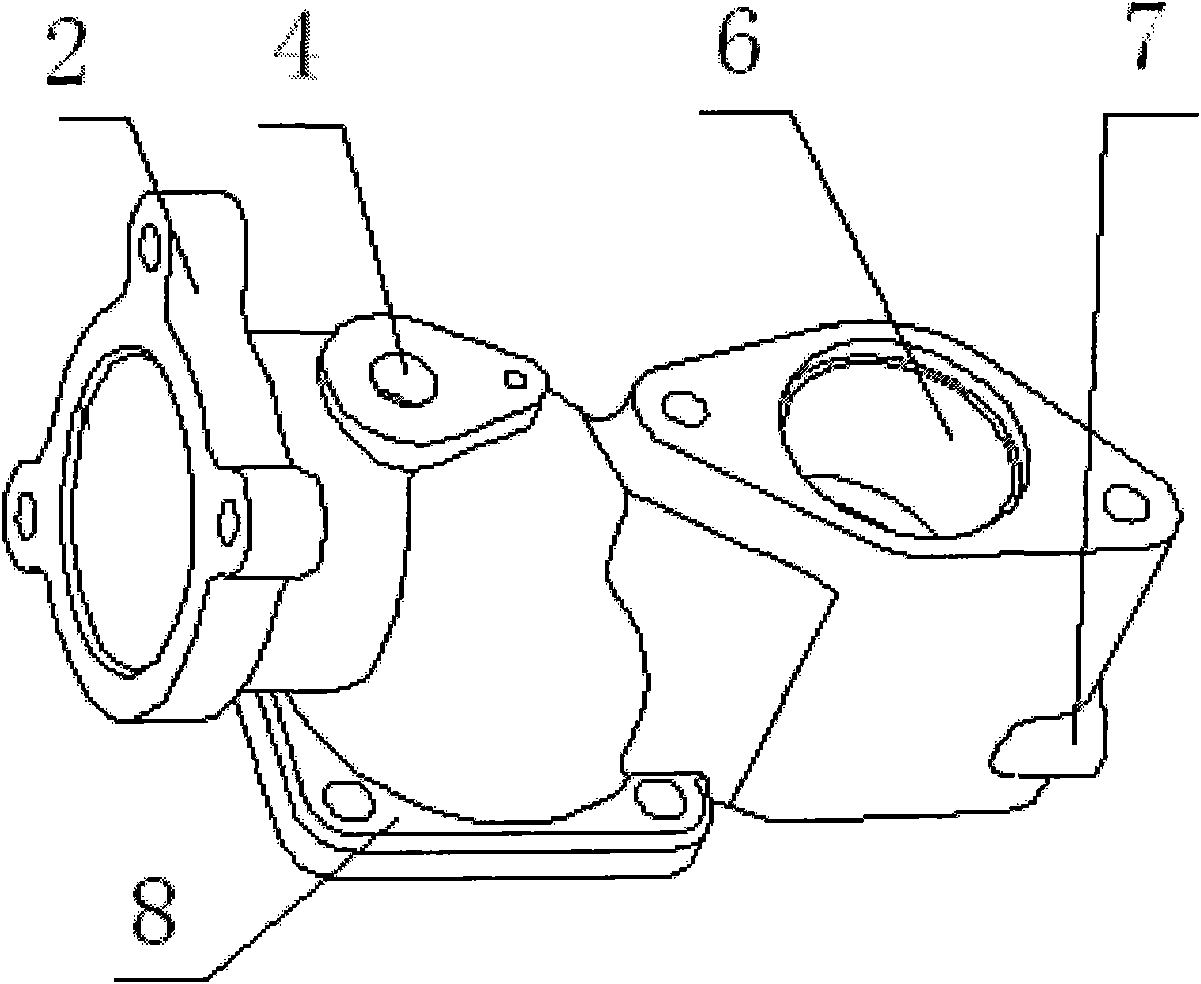

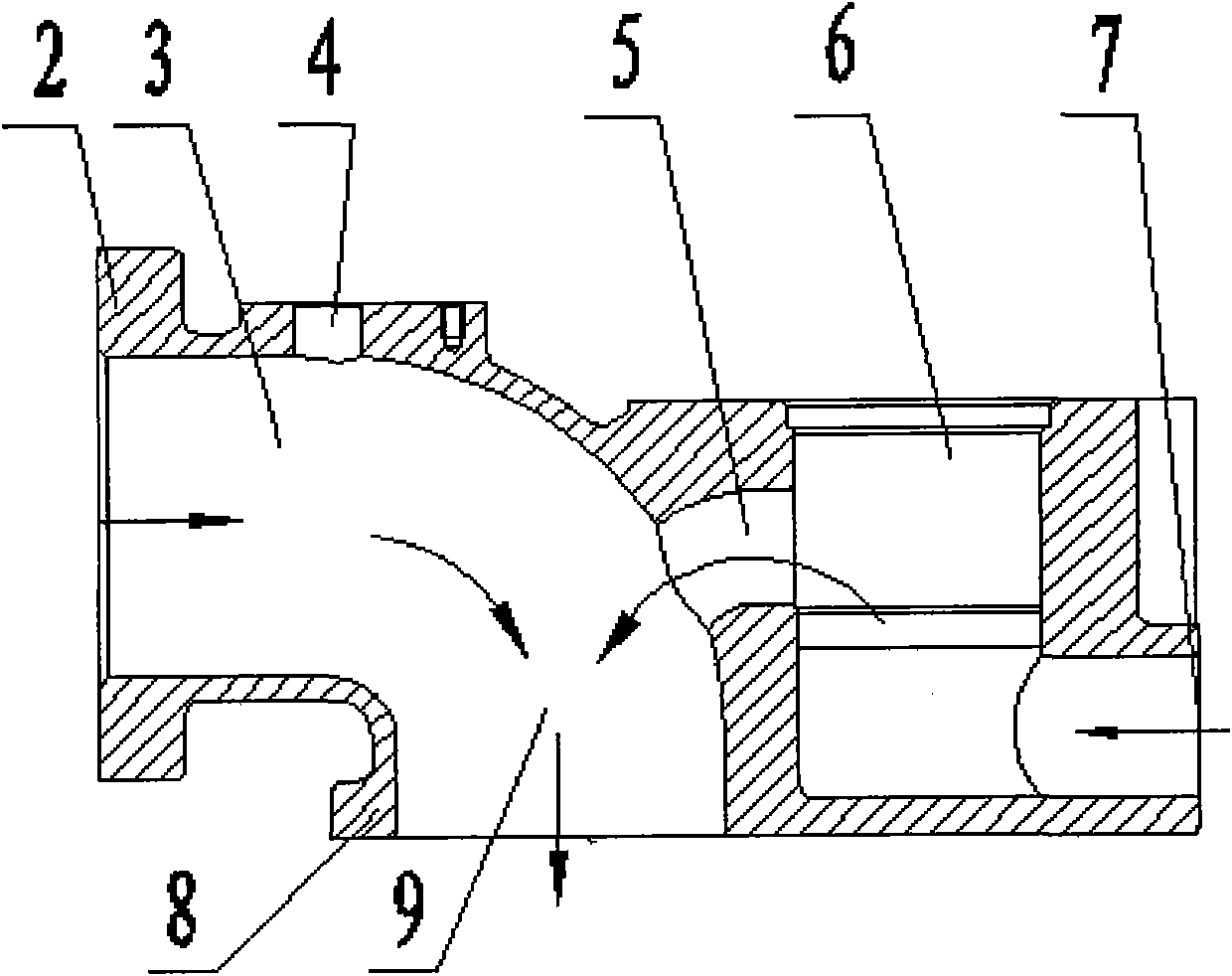

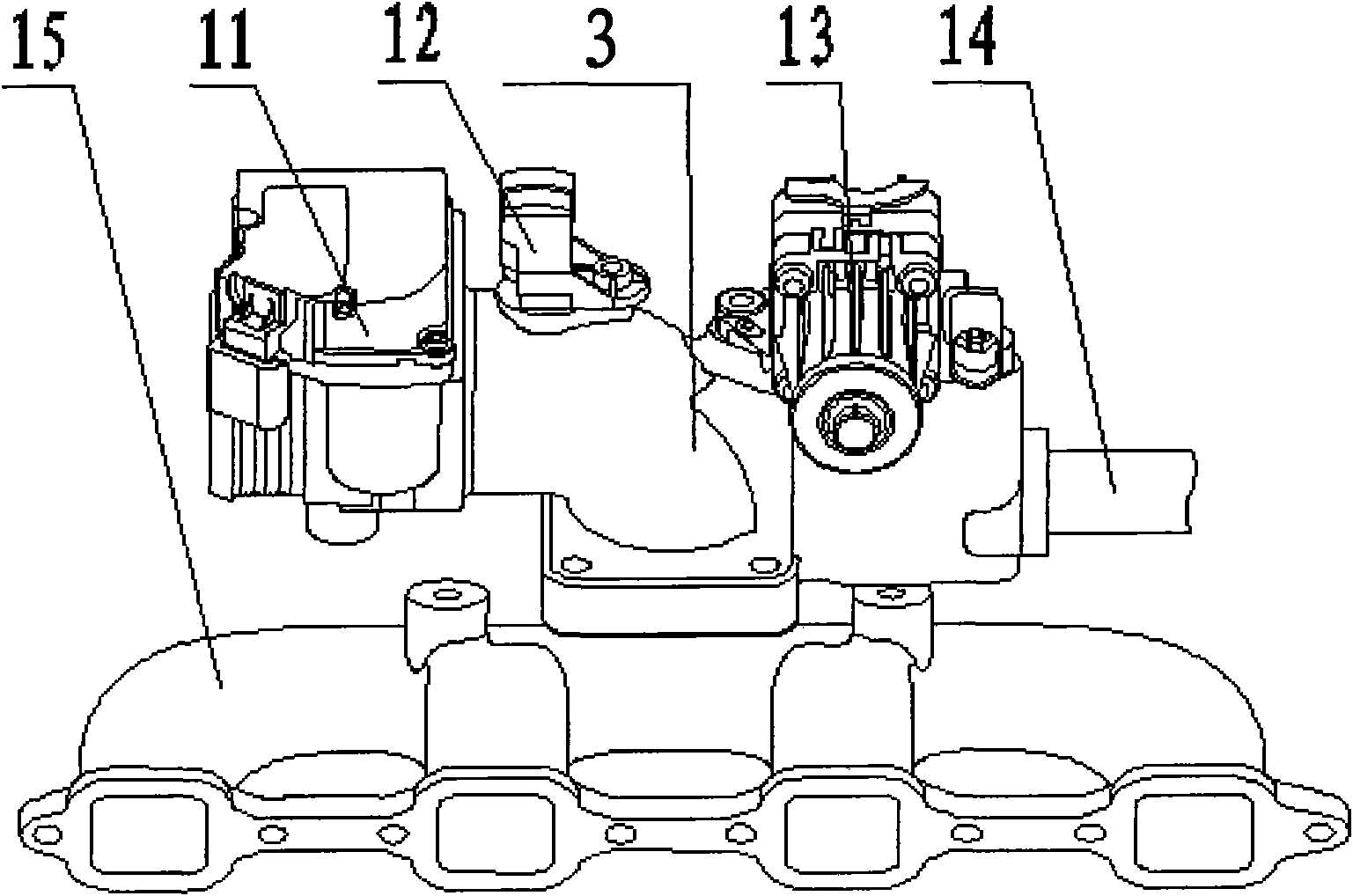

[0015] see figure 1 with figure 2 , a diesel engine air intake connection includes an L-shaped intake pipe 3 and an exhaust gas recirculation valve installation pipe 6, and the two are connected back to back. One port of the intake pipe 3 is the electronic throttle valve installation flange port 2, and the other port is the intake manifold installation flange port 8, and the intake pipe 3 on the side of the electronic throttle valve installation flange port 2 is provided with a sensor installation hole 4. The intake pipe on the side of the flange port 2 of the electronic throttle valve is the intake chamber, and the intake pipe on the side of the flange port 8 of the intake manifold is the mixing chamber 9; and the flange port 8 of the intake manifold is connected to the The exhaust gas recirculation valve installation pipe 6 is adjacent to each other in parallel, and an exhaust gas cavity 5 connected between the intake manifold installation flange port 8 and the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com