Continuous determination method of sodium nitrite-potassium nitrate mixed salt in salt bath

A technology of sodium nitrite and a determination method is applied in the field of determination of nitrate salt bath components and chemical analysis, and achieves the effects of accurate and consistent detection results, low cost and simple detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific embodiments.

[0038] A kind of continuous determination method of salt bath sodium nitrite, potassium nitrate mixed salt, the technical scheme that it adopts comprises following specific steps:

[0039] 1. Sample solution preparation

[0040] Weigh 2.50 g of the finely ground mixed salt of sodium nitrite and potassium nitrate and place it in a 100 ml beaker, dissolve it in water and transfer it to a 250 ml volumetric flask, dilute with water to the maximum scale, shake well, dry filter, and discard 5 ~10 mL of starting solution.

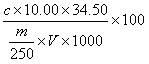

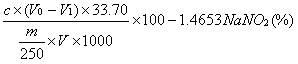

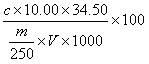

[0041] 2. Calculate the content of sodium nitrite in the sample solution

[0042] Draw 10.00 ml of one-fifth potassium permanganate standard solution with a concentration of 0.1-0.2 mol / L and place it in a 250 ml Erlenmeyer flask, add 20 ml of water and 5 ml of sulfuric acid solution (1+1), shake well, and make Potassium permanganate standard solution is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com