Thyristor pressing mechanism for direct current power transmission converter valve

A technology of direct current transmission and thyristors, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of inconvenient installation and maintenance, uneven force on thyristors, etc., achieve precise pressure control, reduce uneven surface distribution, and maintain stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

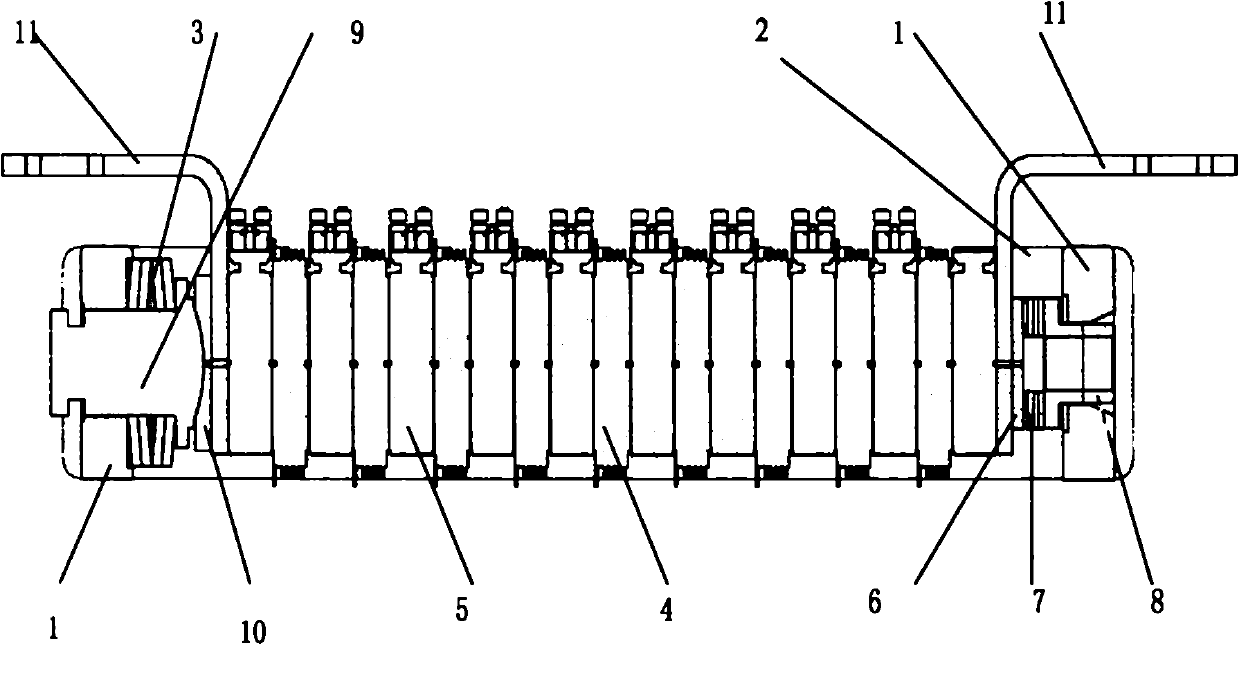

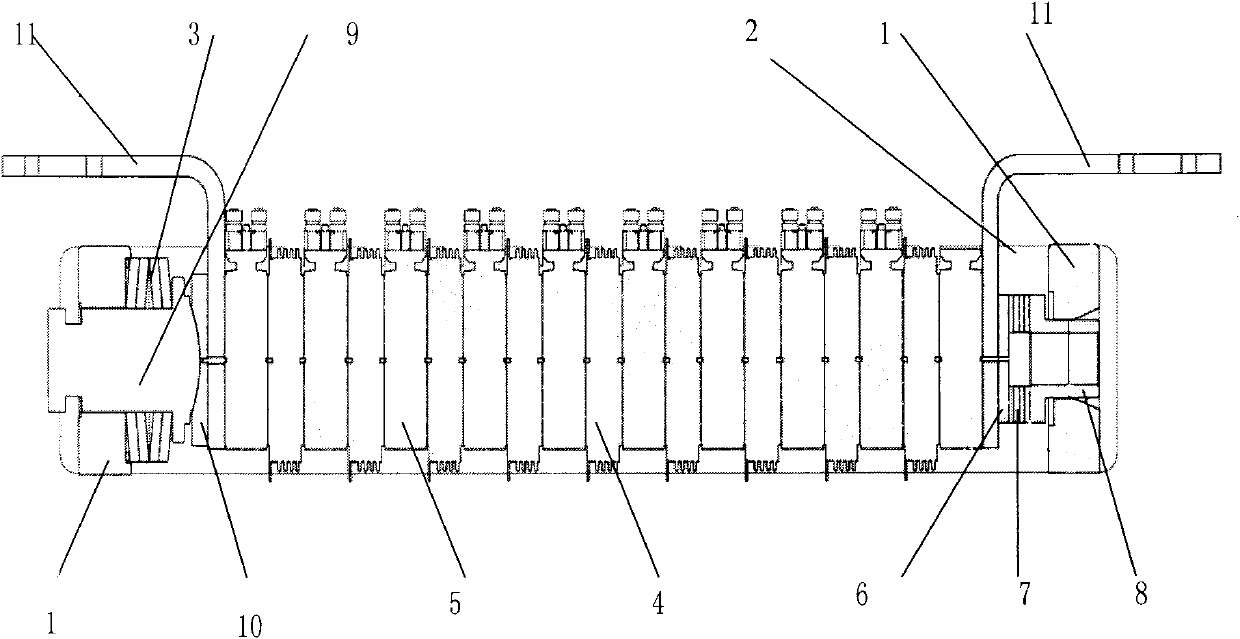

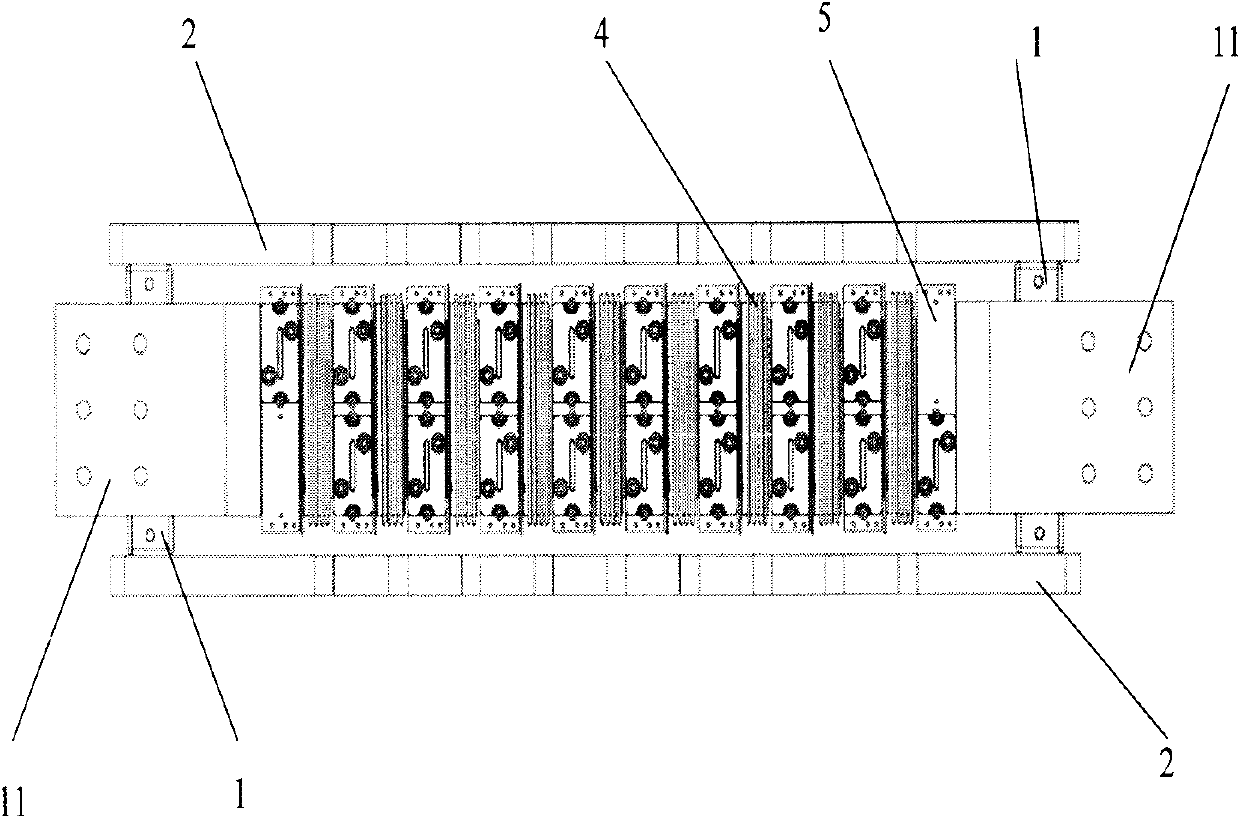

[0028] The thyristor press-fitting mechanism for the DC transmission converter valve of this embodiment includes a metal end plate 1; an insulating pull plate 2; a butterfly spring 3; a thyristor 4; a radiator 5; a pressure dispersion plate 6; a gap gasket 7; Loading joint 8; pressure self-adjusting ball head 9; pressure adjustment adapter block 10; conductive copper bar 11.

[0029] Such as Figure 1-2 Shown: The press-fit structure of the thyristor tube is explained. When the thyristor is pressed, the support frame of the thyristor press-fit mechanism is composed of the insulating pull plate 2 and the metal end plate 1. The metal end plate 1 is used as a platform in the support frame , successively stack the butterfly spring 3, the pressure self-adjusting ball head 9, the pressure adjustment adapter block 10, the conductive copper bar 11, the radiator 5, the thyristor 4, the pressure dispersion plate 7 and the hydraulic loading joint 9. The external hydraulic loading mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com