Method for Improving the Quality of Adiponitrile

A technology of adiponitrile and impurities, applied in the field of improving the quality of adiponitrile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Air was passed through a Wedeco ozone generator, Model SMA 500S, at a rate of 30 Nm3 / hr to produce an ozone concentration of 1.0% by weight in the air. An ozone-containing air stream is fed to the PFSMR along with a refined adiponitrile stream. The adiponitrile feed rate was 13.2 metric tons / hour. The static mixer included Sulzer SMV elements. There are a total of six mixing sections, and each section is 6 feet (1.8 m) long, providing a total static mixer length of 36 feet (11 m). Each 6-foot (1.8-m) long segment includes six static mixer elements, each of which is 6 inches (15.2 cm) long, wherein each of the elements passes through a 6-inch (15.2 cm) opening Tubes, ie pipes without static mixer elements, are separated from each other. The diameter of the static mixer is 3 inches (7.6 cm). Based on the measured properties, the mass transfer parameter k L a is calculated to be about 0.7 seconds -1 . The adiponitrile feed contained 5.7 ppm phosphorus in the form of...

Embodiment 2

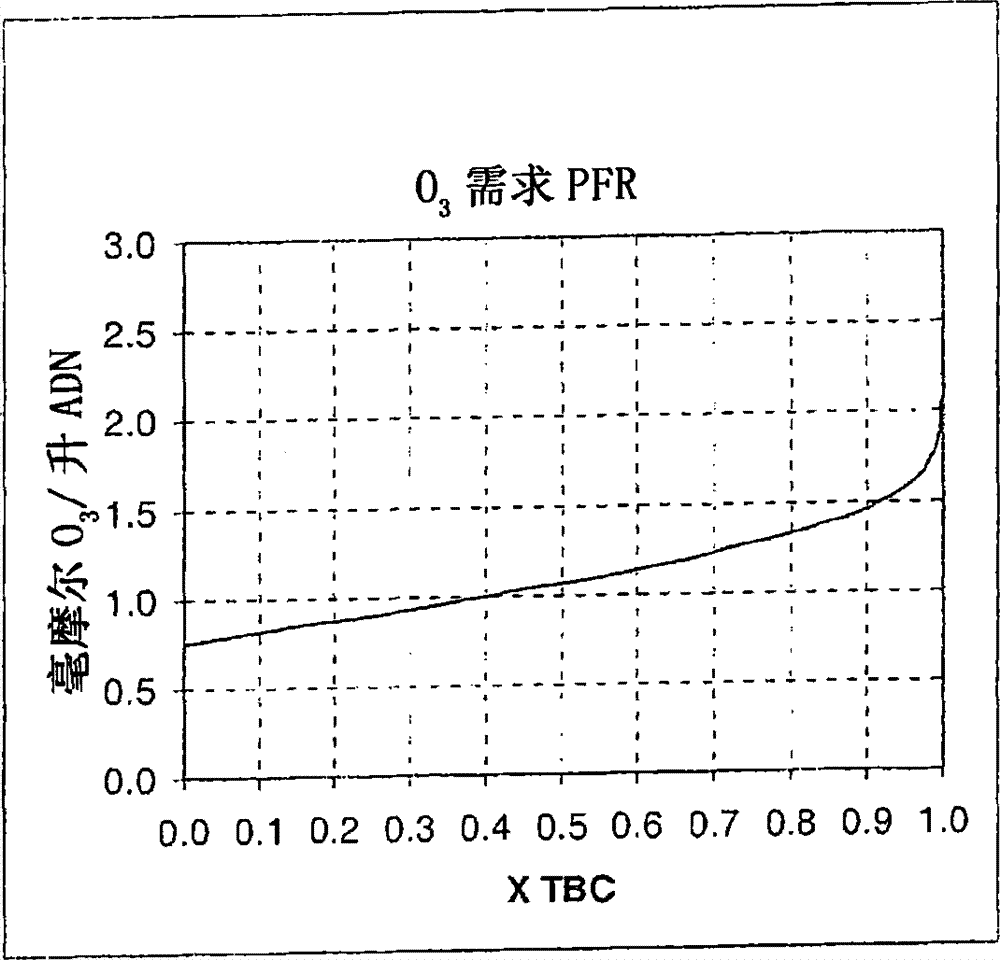

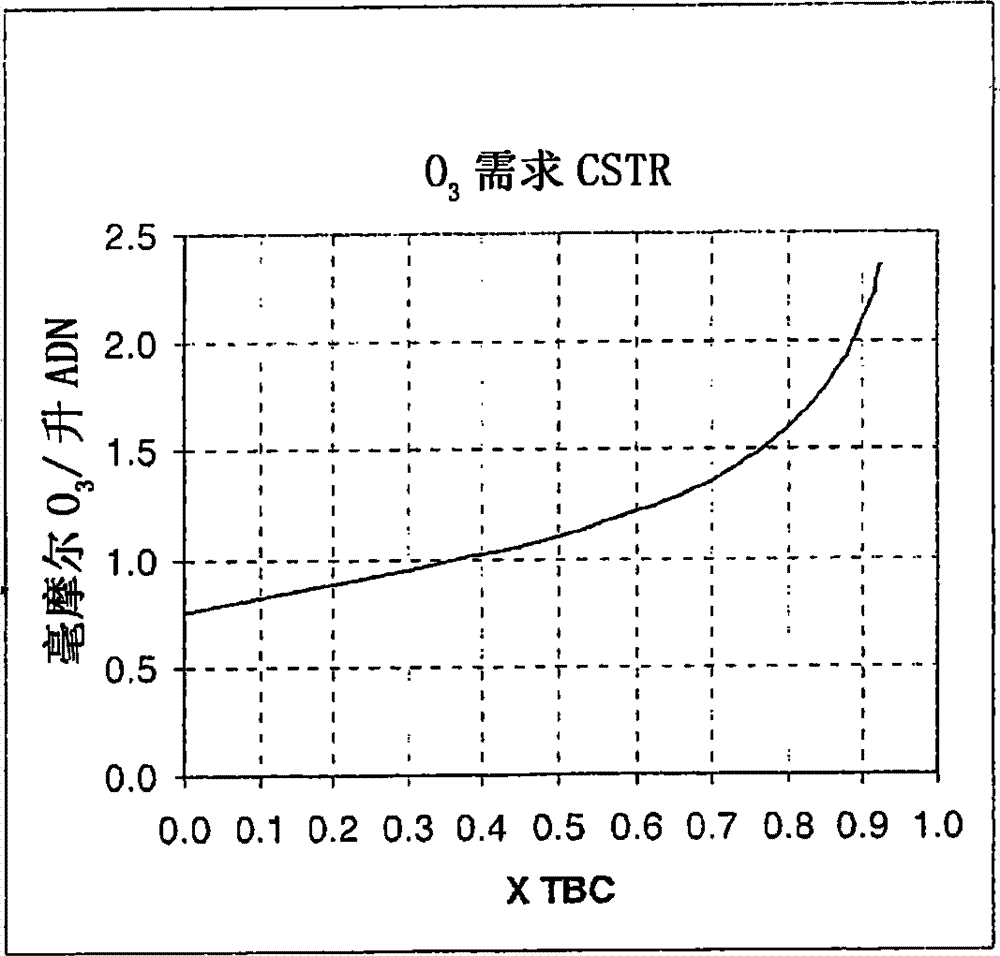

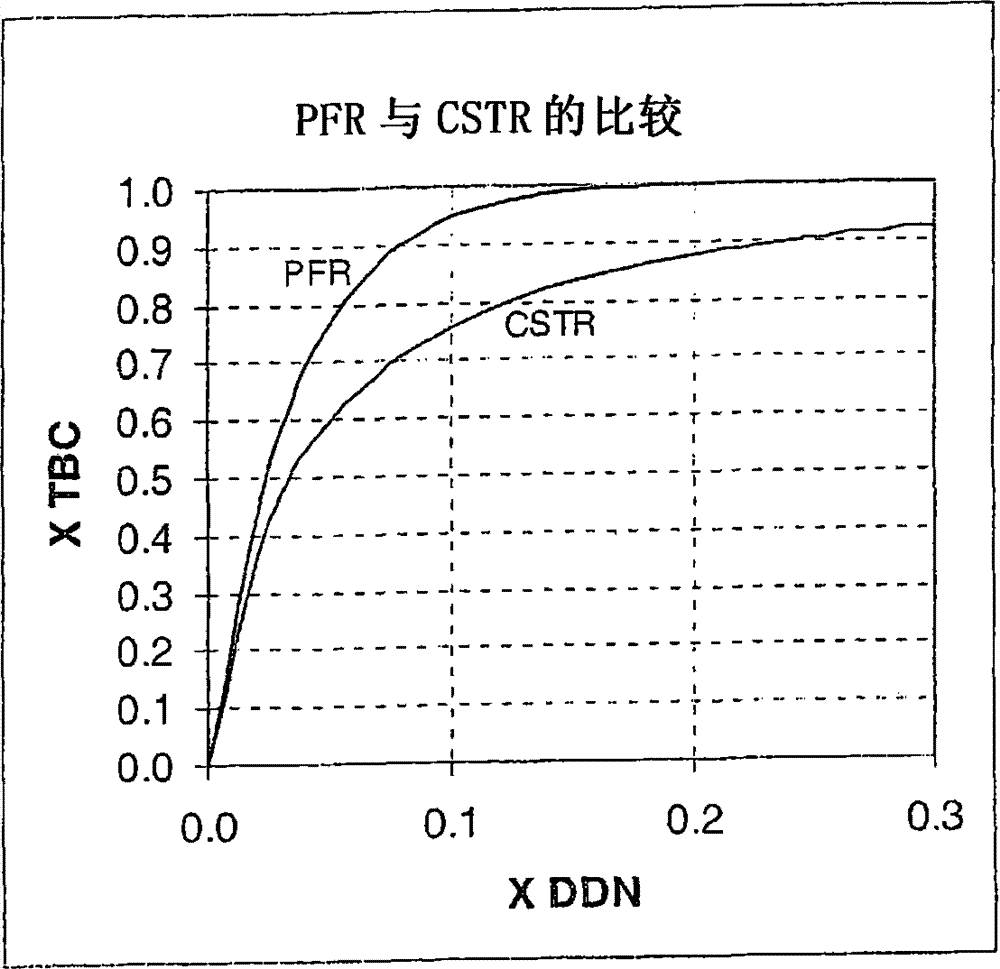

[0040] This example shows the improved ozone utilization achieved by performing the reaction in a plug flow reactor (PFR) relative to a back-mix reactor (CSTR). This example is a computer simulation of a process based on a conventional reactor selectivity model using experimentally determined data on the relative reaction rates of various impurities with ozone. In this example, the ADN feed to the two simulated reactors contained the following impurities: 10 ppm of P(III), 50 ppm of CPI, 25 ppm of TBC and 675 ppm of DDN.

[0041] The reaction stoichiometry for the reaction of ozone with the impurities present is 1 mole of ozone each per mole of P(III), CPI and DDN; for TBC, the stoichiometry is 3 moles of ozone per mole of TBC. Experiments were performed in which refined ADN was reacted with ozone in a CSTR at atmospheric pressure and ambient temperature. Depletion of P(III), CPI, TBC and DDN in CSTR was measured. These data were fitted to a CSTR reactor design model derived...

Embodiment 3

[0042] This example shows the beneficial effect of reducing HMI yield during HMD production by treating ADN with ozone to destroy TBC prior to hydrogenation.

[0043] 1 part by weight of ADN was continuously mixed with 6 parts by weight of anhydrous ammonia. This mixture is fed to a bed of heterogeneous iron catalyst together with a stoichiometric excess of hydrogen. The stoichiometric amount of hydrogen is 4 moles of hydrogen per mole of ADN. The reactor was operated at a pressure of about 5000 psi (34.5 MPa). The reactor feed temperature is about 100°C and the temperature increases along the length of the bed due to the heat of reaction of ADN with hydrogen.

[0044] Initially, ozonated ADN was fed to the reactor for a period of 250 hours. The conversion yield from ADN to HMI averaged 0.10% (moles of HMI formed per mole of ADN reacted x 100%) over this time period when the ozonated ADN was fed to the reactor. The ADN feed was then converted to unozone-treated ADN and run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com