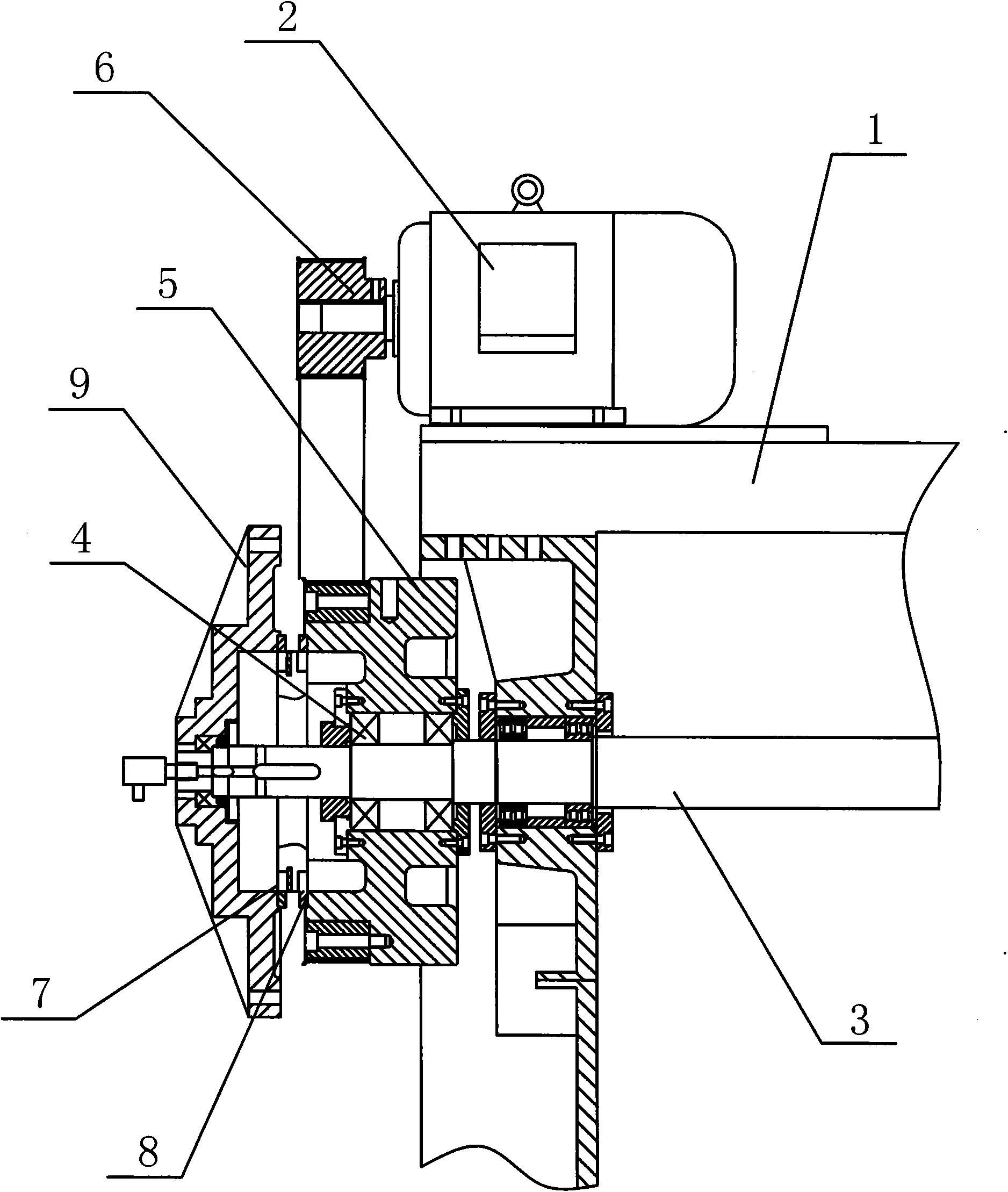

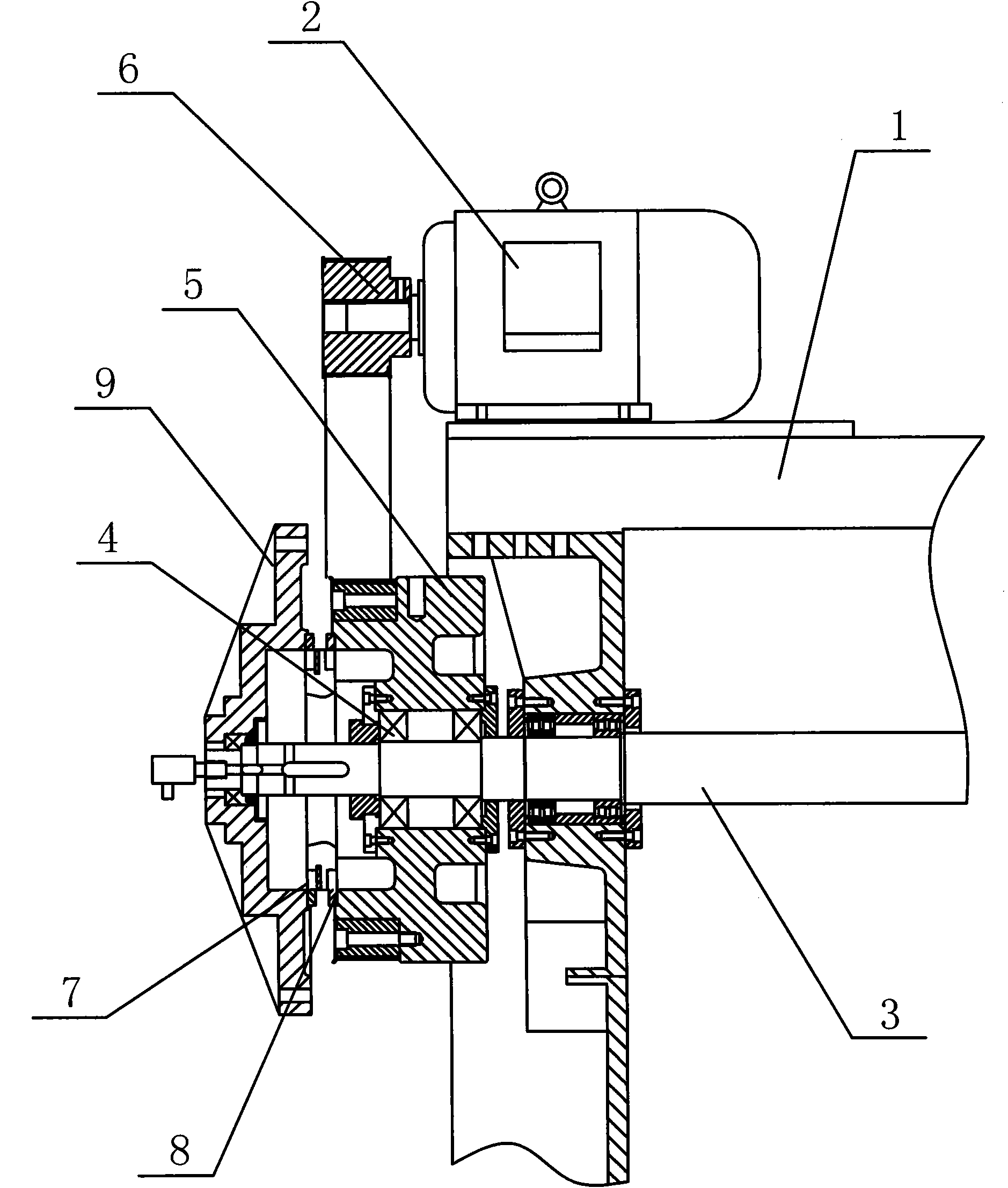

Main driving structure of transverse cutting machine

A technology of cross-cutting machine and main drive, which is applied in the direction of metal processing, etc., can solve the problems of unbalanced force on the tool holder, uneven force on one-way cross-cutting machine, etc., and achieve the effect of increasing inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the main transmission structure of the cross-cutting machine of the present invention. In this embodiment, a main transmission structure of the cross-cutting machine includes a main motor 2 arranged on the frame 1, and the main motor 2 is a variable frequency motor, so that The speed can be adjusted flexibly, and the output end of the main motor 2 is connected to the transmission shaft 3 of the cross-cutting machine, and one end of the transmission shaft 3 is provided with an energy storage flywheel 5 through a bearing 4, and the energy storage flywheel 5 adopts carbon fiber Reinforced epoxy resin composite material, its interior is vacuum, its diameter is 200mm, mass is 12g, vacuum degree is 10 -4 Below Pa, and the energy storage flywheel 5 is connected to the output end of the main motor 2 through the synchronous wheel 6, the outside of the energy storage flywheel 5 is also provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com