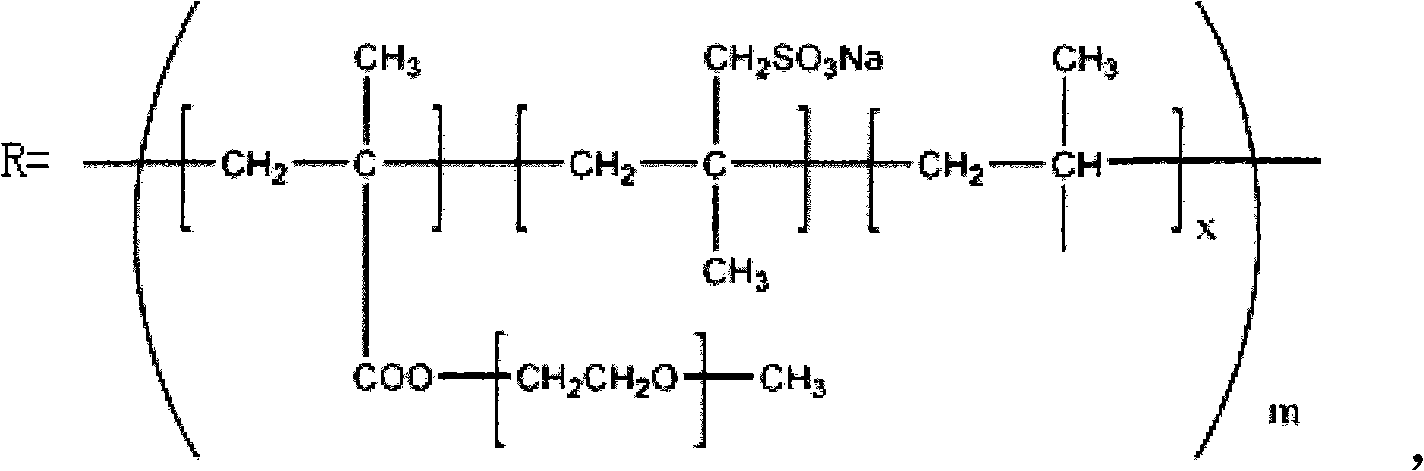

Polycarboxylic acid-alcohol amine polymer grinding aid and preparation method thereof

An alkanolamine type, polymer technology, applied in cement production and other directions, can solve problems such as endangering building safety, and achieve the effects of improving grinding aid performance, convenient operation and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

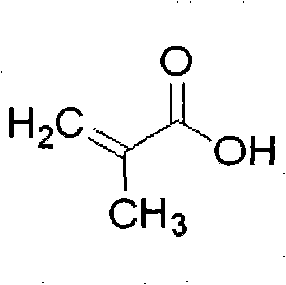

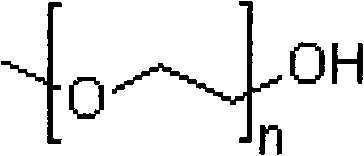

[0053] Molar ratio: methacrylic acid: polyethylene glycol monomethyl ether: sodium methacrylate: triethanolamine = 3.0: 1.0: 1.0: 1.0 Raw materials are prepared; the molecular weight of polyethylene glycol monomethyl ether is 1000.

[0054]The above raw materials, initiator ammonium persulfate, and polymerization inhibitor hydroquinone were all diluted with deionized water into aqueous solutions with a concentration of 32%.

[0055] In a reaction kettle equipped with an electric stirrer, a condenser, a thermometer, and heated in a water bath, add methacrylic acid and polyethylene glycol monomethyl ether aqueous solution according to the above molar ratio to raise the temperature and stir. When the temperature is raised to 60°C, add diluted hydroquinone aqueous solution into the reactor, the mass of hydroquinone before dilution is 0.03% of the total mass of reactants, continue to heat up and stir, and keep it at 80°C for 1 hour. Keep the temperature at 80°C, add sodium methacry...

Embodiment 2

[0057] Molar ratio: methacrylic acid: polyethylene glycol monomethyl ether: sodium methacrylate: triethanolamine = 3.5: 1.0: 1.0: 1.5 Raw materials are prepared; the molecular weight of polyethylene glycol monomethyl ether is 1200.

[0058] The above raw materials, initiator ammonium persulfate, and polymerization inhibitor hydroquinone were all diluted with deionized water into aqueous solutions with a concentration of 35%.

[0059] In a reaction kettle equipped with an electric stirrer, a condenser, a thermometer, and heated in a water bath, add methacrylic acid and polyethylene glycol monomethyl ether aqueous solution according to the above molar ratio to raise the temperature and stir. When the temperature is raised to 40°C, add diluted hydroquinone aqueous solution into the reaction kettle, the mass of hydroquinone before dilution is 0.05% of the total mass of reactants, continue to heat up and stir, and keep it at 70°C for 2 hours. Keep the temperature at 70°C, add sodiu...

Embodiment 3

[0061] Molar ratio: methacrylic acid: polyethylene glycol monomethyl ether: sodium methacrylate: triethanolamine = 4.0: 1.0: 1.0: 1.0 Raw materials are prepared; the molecular weight of polyethylene glycol monomethyl ether is 1000.

[0062] The above raw materials, initiator ammonium persulfate, and polymerization inhibitor hydroquinone were all diluted with deionized water into aqueous solutions with a concentration of 38%.

[0063] In a reaction kettle equipped with an electric stirrer, a condenser, a thermometer, and heated in a water bath, add methacrylic acid and polyethylene glycol monomethyl ether aqueous solution according to the above molar ratio to raise the temperature and stir. When the temperature rises to 50°C, add diluted hydroquinone aqueous solution into the reaction kettle, the mass of hydroquinone before dilution is 0.06% of the total mass of reactants, continue to heat up and stir, and keep it at 75°C for 1.5 hours. Keep the temperature at 75°C, add sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com