Preparation method of alpha-mangostin

A technology of mangostin and bamboo, which is applied in the field of preparation of mangostin extraction from plants, can solve the problems of not extracting mangostin industrialized production process disclosure, etc., and achieve the benefits of large-scale production operations, less pollution, and less energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

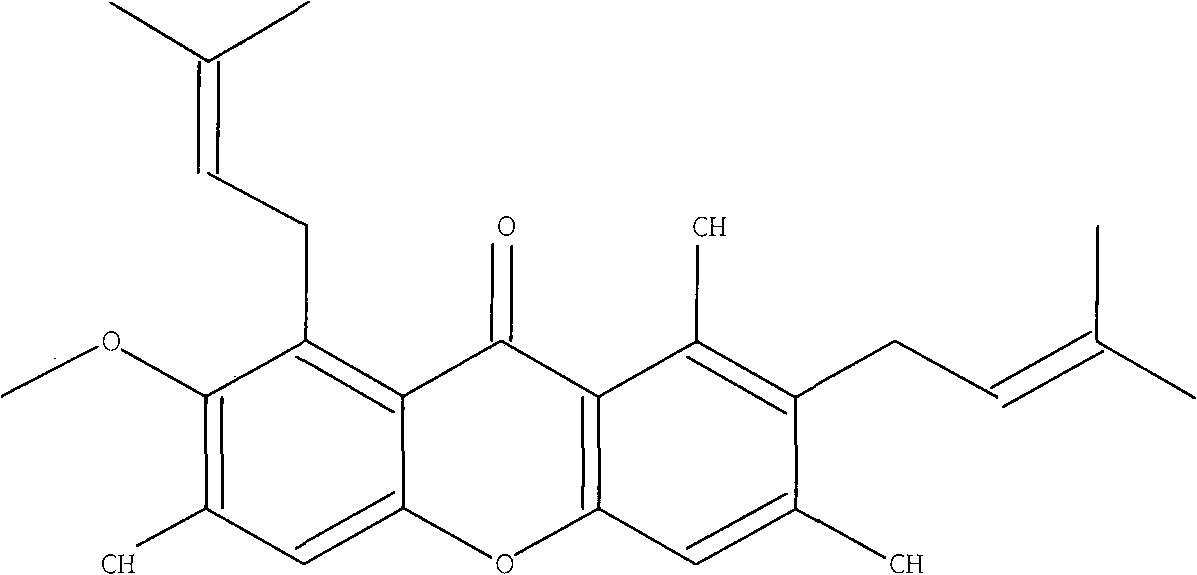

Image

Examples

Embodiment 1

[0018] Get mangosteen husk 10Kg, pulverize, add to CO 2 In the supercritical extractor, ethanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 2%, the extraction pressure is 50MPa, the temperature is 100°C, and the CO 2 The flow rate is 10L / min, the extraction time is 80min, and the extract is obtained, which is added to the chromatographic column of nylon 6 polyamide, and is eluted with a mixed solvent of dichloromethane and methanol with a volume ratio of 8:1 as the eluent, and a part of the eluted The liquid point is developed on the polyamide film with the above-mentioned eluent as a supporting detection, and the fraction corresponding to Rf=4-4.5 on the polyamide film is collected, the solvent is recovered, crystallized, separated and crystallized, recrystallized with toluene, separated Crystallization, washing and drying yielded 35.8 g of mangostin, which was detected by HPLC with a purity of 97.6%.

Embodiment 2

[0020] Get mangosteen husk 10Kg, pulverize, add to CO 2 In the supercritical extractor, ethanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 4%, the extraction pressure is 80MPa, the temperature is 120°C, and the CO 2 The flow rate is 30L / min, the extraction time is 100min, and the extract is obtained, which is added to a polyamide 6 polyamide chromatography column, and eluted with a mixed solvent of dichloromethane-methanol with a volume ratio of 8:1 as the eluent, and part of the washed The liquid removal point is developed on the polyamide film with the above-mentioned eluent as a supporting detection, and the fraction corresponding to Rf=4-4.5 on the polyamide film is collected, the solvent is recovered, crystallized, separated and crystallized, recrystallized with toluene, The crystals were separated, washed and dried to obtain 40.0 g of mangostin, which was detected by HPLC with a purity of 96.2%.

Embodiment 3

[0022] Get mangosteen husk 10Kg, pulverize, add to CO 2 In the supercritical extractor, ethanol is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 3%, the extraction pressure is 60MPa, the temperature is 110°C, and the CO 2 The flow rate is 20L / min, the extraction time is 90min, and the extract is obtained, which is added to the polyamide 6 polyamide chromatography column, and is eluted with a dichloromethane-methanol mixed solvent with a volume ratio of 8:1 as the eluent. The liquid removal point is developed on the polyamide film with the above-mentioned eluent as a supporting detection, and the fraction corresponding to Rf=4-4.5 on the polyamide film is collected, the solvent is recovered, crystallized, separated and crystallized, recrystallized with toluene, The crystals were separated, washed and dried to obtain 38.3 g of mangostin, which was detected by HPLC with a purity of 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com