Antifriction bearing multi-functional fatigue life test bed

A rolling bearing, fatigue life technology, applied in the field of multifunctional fatigue life test device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

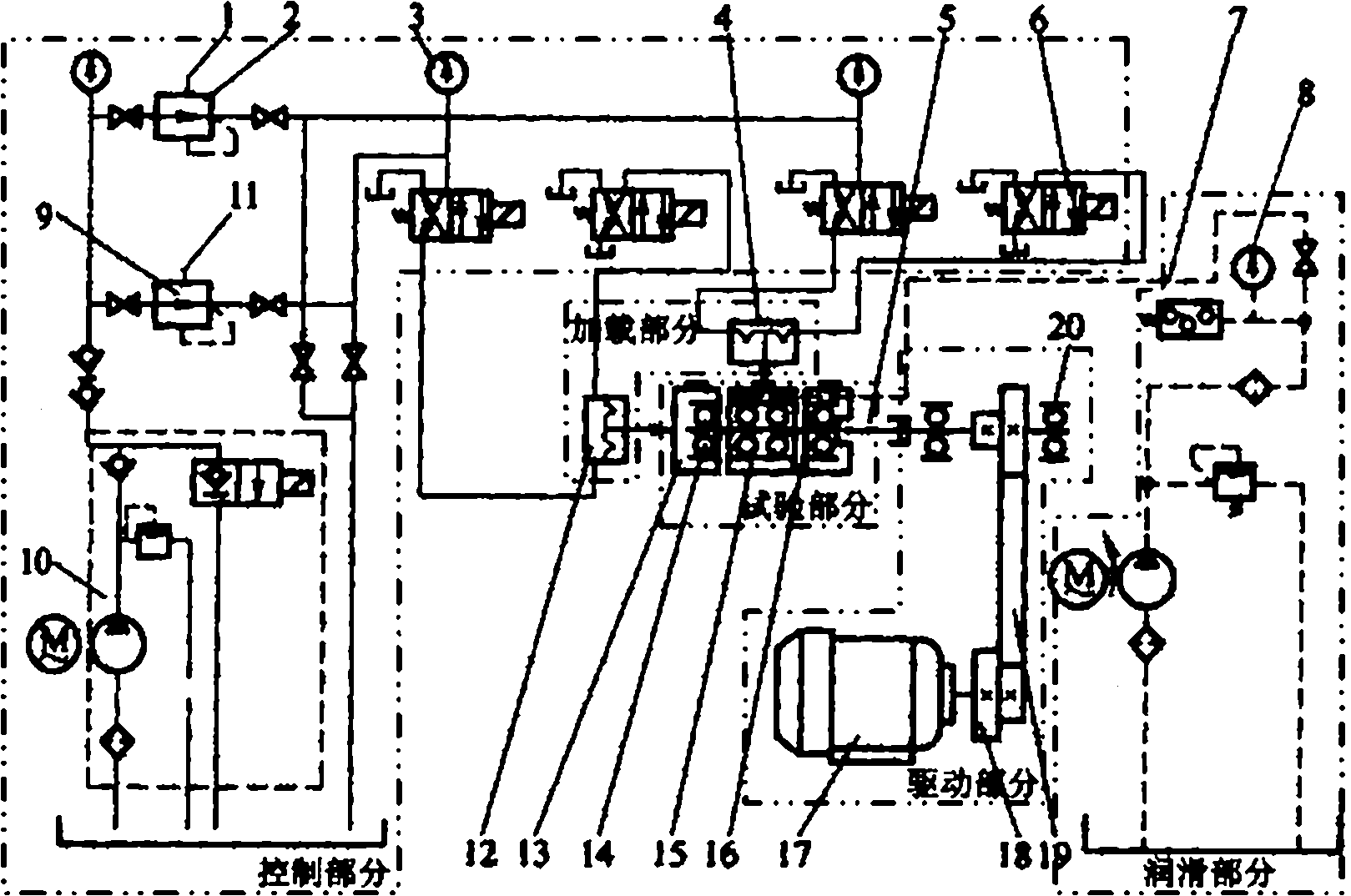

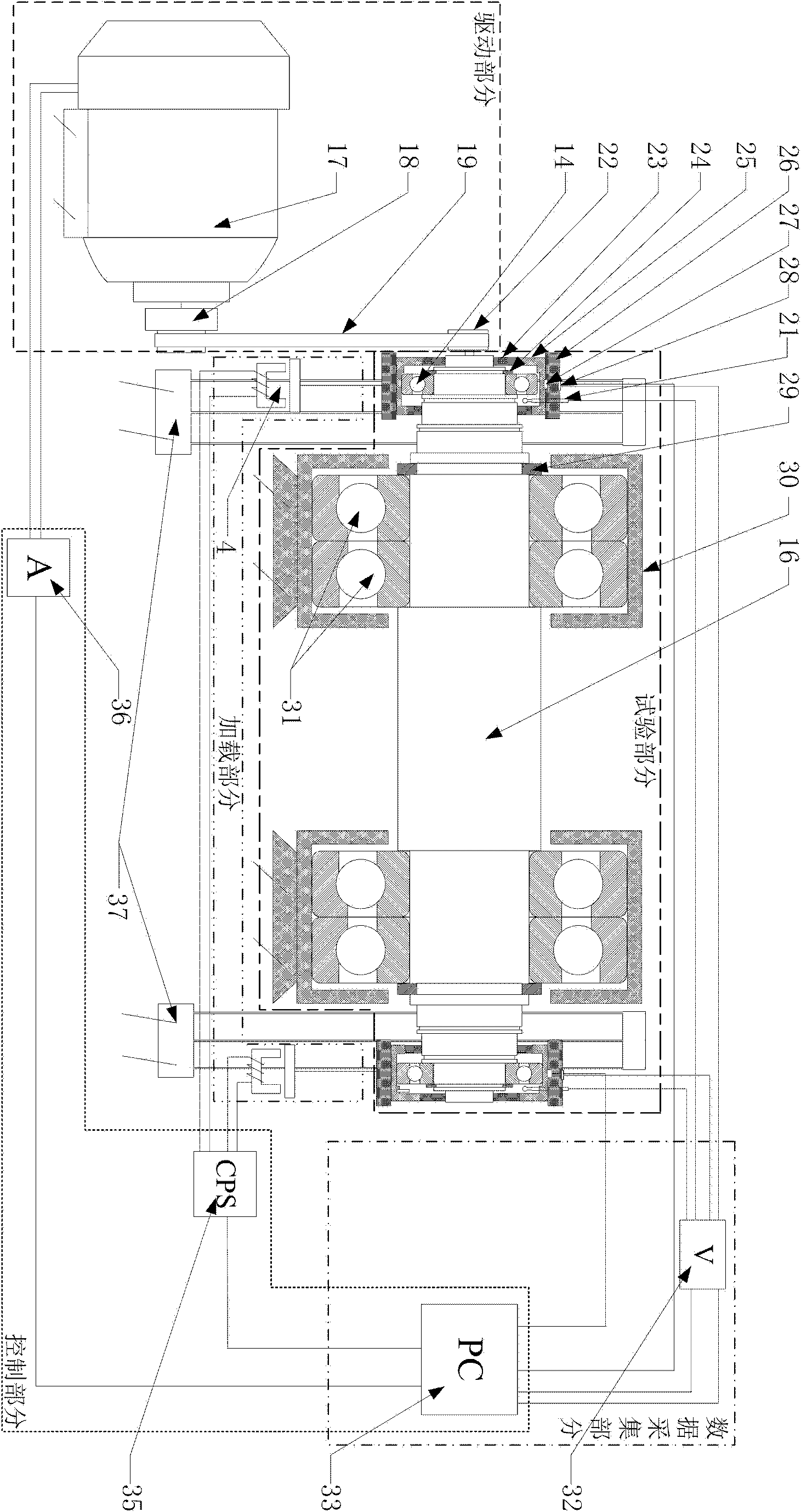

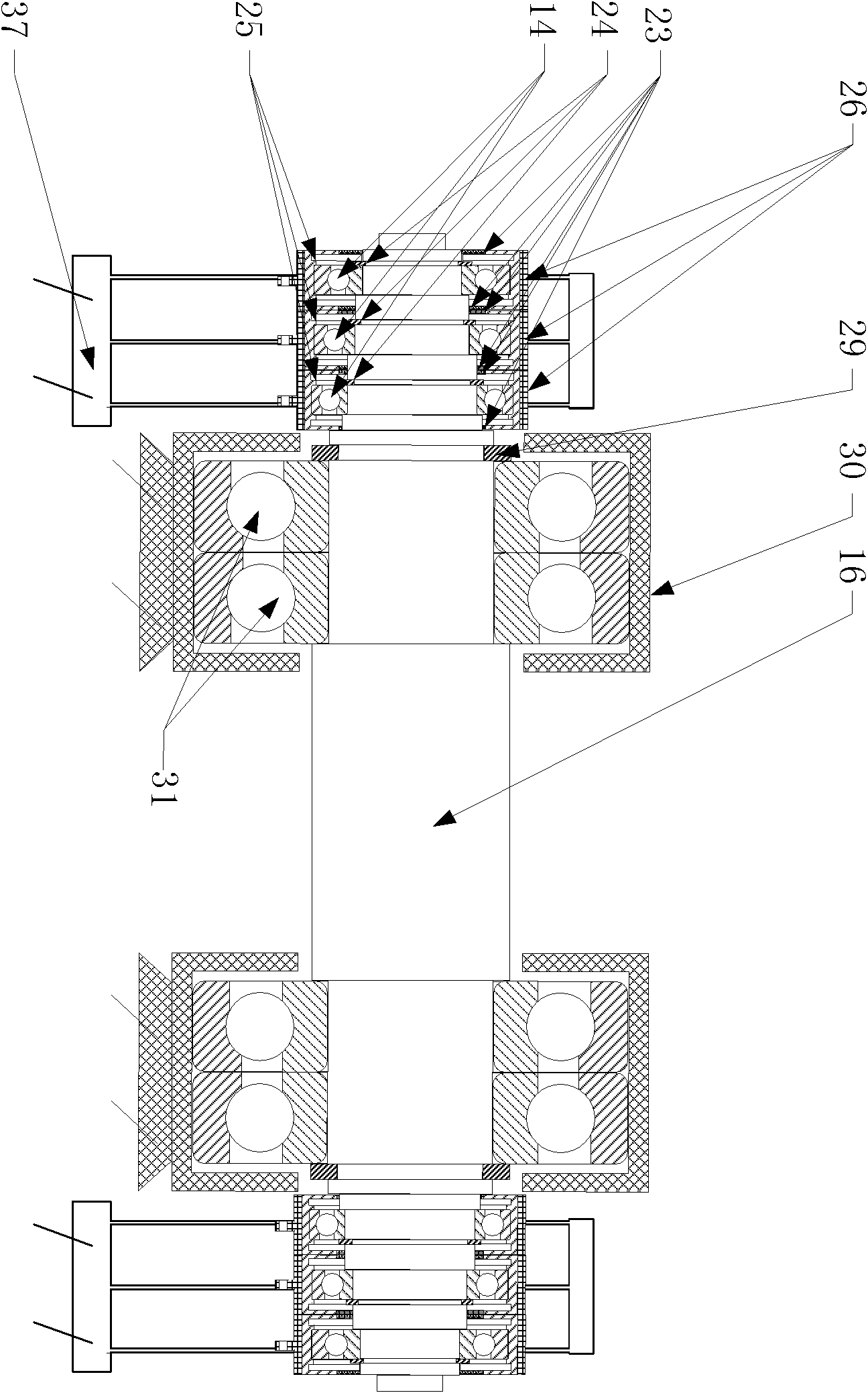

[0054] figure 1 It is the structural diagram of ABLT-1A type automatic control rolling bearing fatigue life and reliability strengthening testing machine. ABLT-1A consists of a test part, a loading part, a control part, a driving part and a lubricating part, including radial loading valve 1, pressure valve 2, pressure gauge 3, radial loading hydraulic cylinder 4, coupling 5, Electromagnetic reversing valve 6, lubricating system oil circuit 7, pressure gauge 8, pressure valve 9, high pressure pump station 10, axial loading force 11, axial loading cylinder 12, end load body 13, test bearing 14, medium load body 15 , Test main shaft 16, motor 17, multi-ribbed pulley 18, multi-ribbed belt 19, support bearing 20. The test part is composed of test bearing 14 and medium load body 15; the loading part is composed of radial loading hydraulic cylinder 4 and axial loading hydraulic cylinder 12. Apply radial load and axial load to the test bearing 14 and the medium load body 15 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com