Composite optical film

A technology of optical film and light-concentrating layer, which is applied in the field of composite optical film, can solve the problems of not conforming to the trend of light and thin, increasing the thickness of the backlight module, and the complexity of the backlight module, etc., to achieve the effect of increasing light utilization efficiency, easy assembly, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] Preparation of composite optical film of the present invention

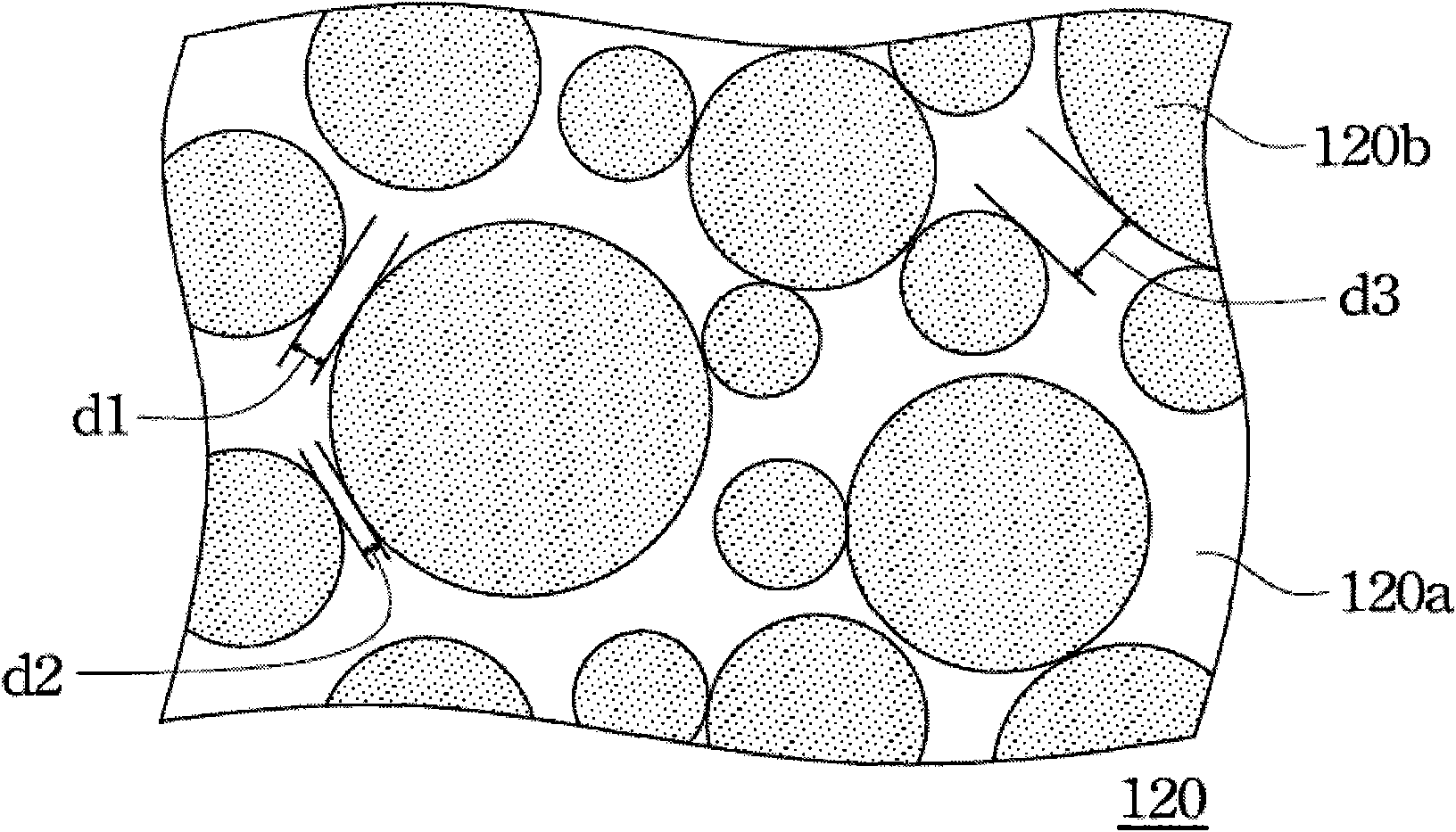

[0082] Firstly, the light diffusion layer 120 is formed on the base material 110 by coating, spraying or pasting. Taking coating as an example, the coating containing the micro-beads 120 b and the bonding agent 120 a can be coated on the substrate 110 . There is no particular limitation on the number of times of coating in the above-mentioned coating method, and it can be applied once or multiple times. Among them, multiple coatings can utilize a little fluidity before the paint is dry, so that the micro-beads 120b on the upper layer fill the depressions formed between the micro-beads 120b on the lower layer, so as to improve the tightness of the arrangement of the micro-beads 120b , the thickness of the light diffusion layer 120 can also be increased.

[0083] Next, the light-gathering layer 130 is formed on the light-diffusing layer 120, and the formation method can be direct lamination or coating. The...

specific Embodiment

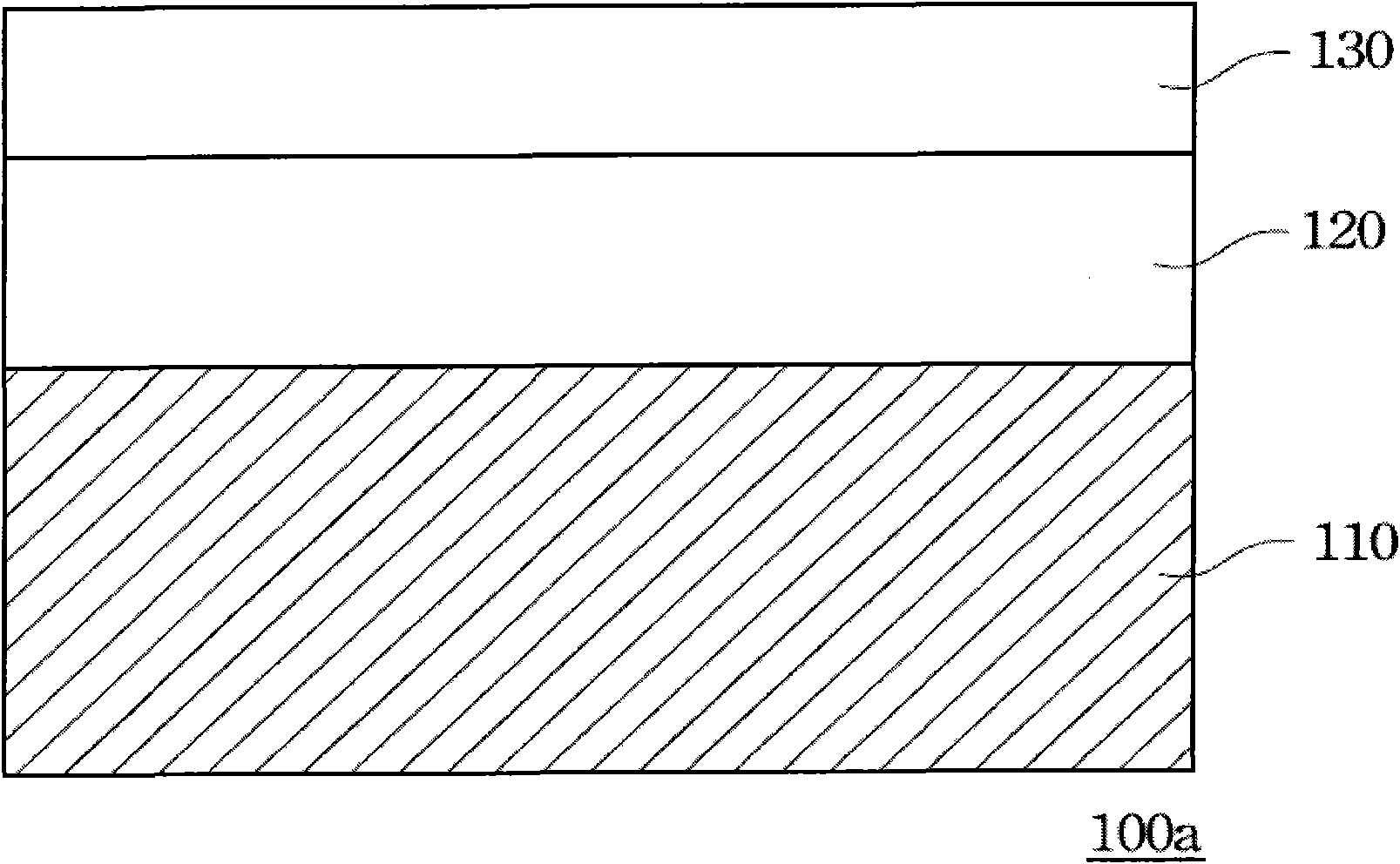

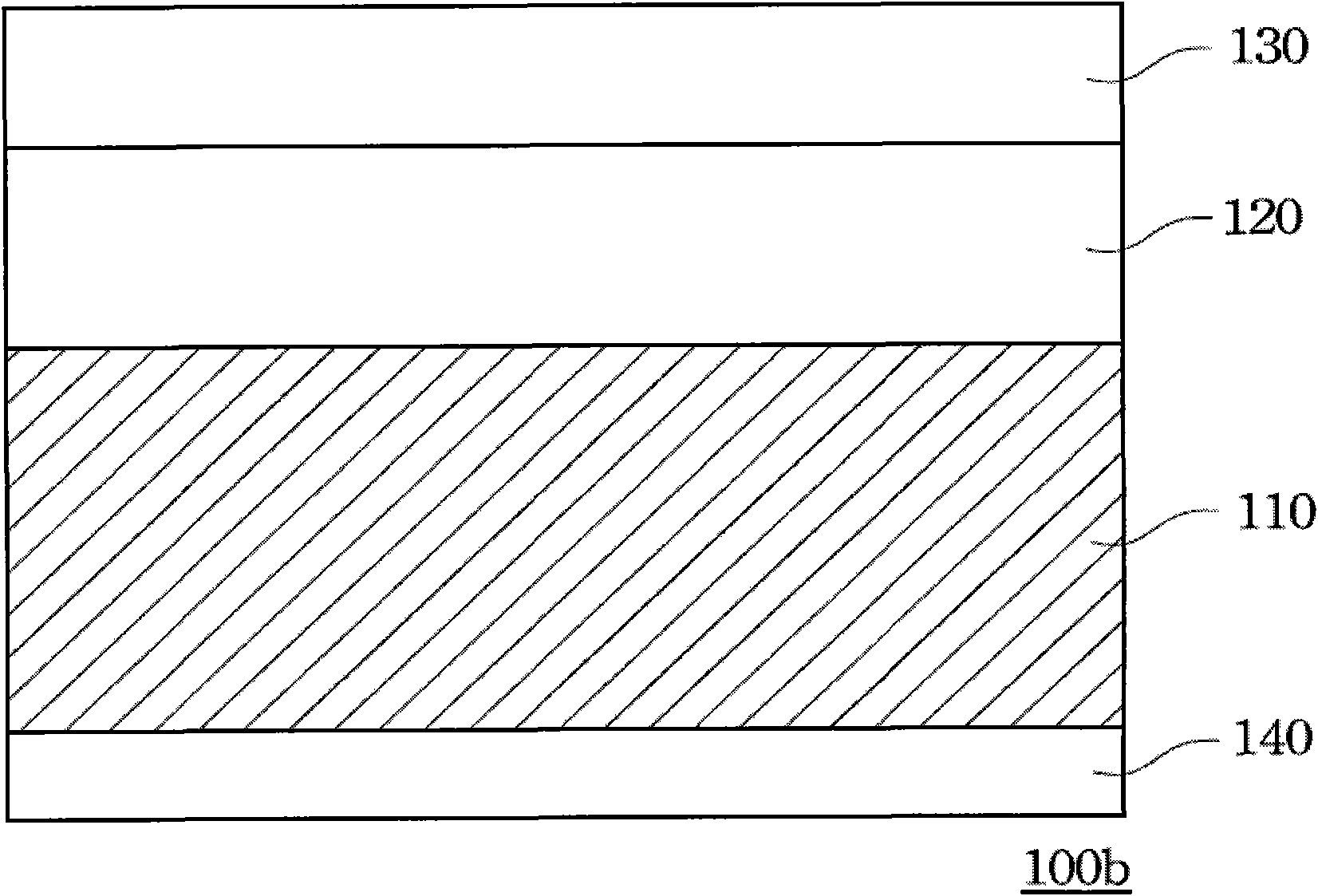

[0085] like image 3 ,for Figure 1A The cross-sectional structure schematic diagram of the specific embodiment.

[0086] exist image 3 Among them, the composite optical film 300 a has a substrate 310 , a light diffusing layer 320 and a light concentrating layer 330 in sequence from bottom to top. The light-diffusing layer 320 is composed of a coating having a concave-convex microstructure, and the average thickness of the light-diffusing layer 320 is H. The coating material of the light diffusion layer 320 contains a bonding agent 320a and microbeads 320b.

[0087] The light concentrating layer 330 on the light diffusing layer 320 has a plurality of prism columnar structures 330a, which can be used as light concentrating microstructures. The distance between adjacent prism columnar structures 330a is D, and the apex angle thereof is 40°-120°. The forming method of the prism columnar structure 330a may be slit die coating, micro gravure coating or roller coating. The resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com