Surface treatment apparatus

A technology of surface treatment device and supply device, applied in feeding device, chemical/physical process, chemical/physical/physical-chemical process, etc., can solve the problems of increased calorific value, corrosion, pump damage, etc. The effect of suppressing uneven treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

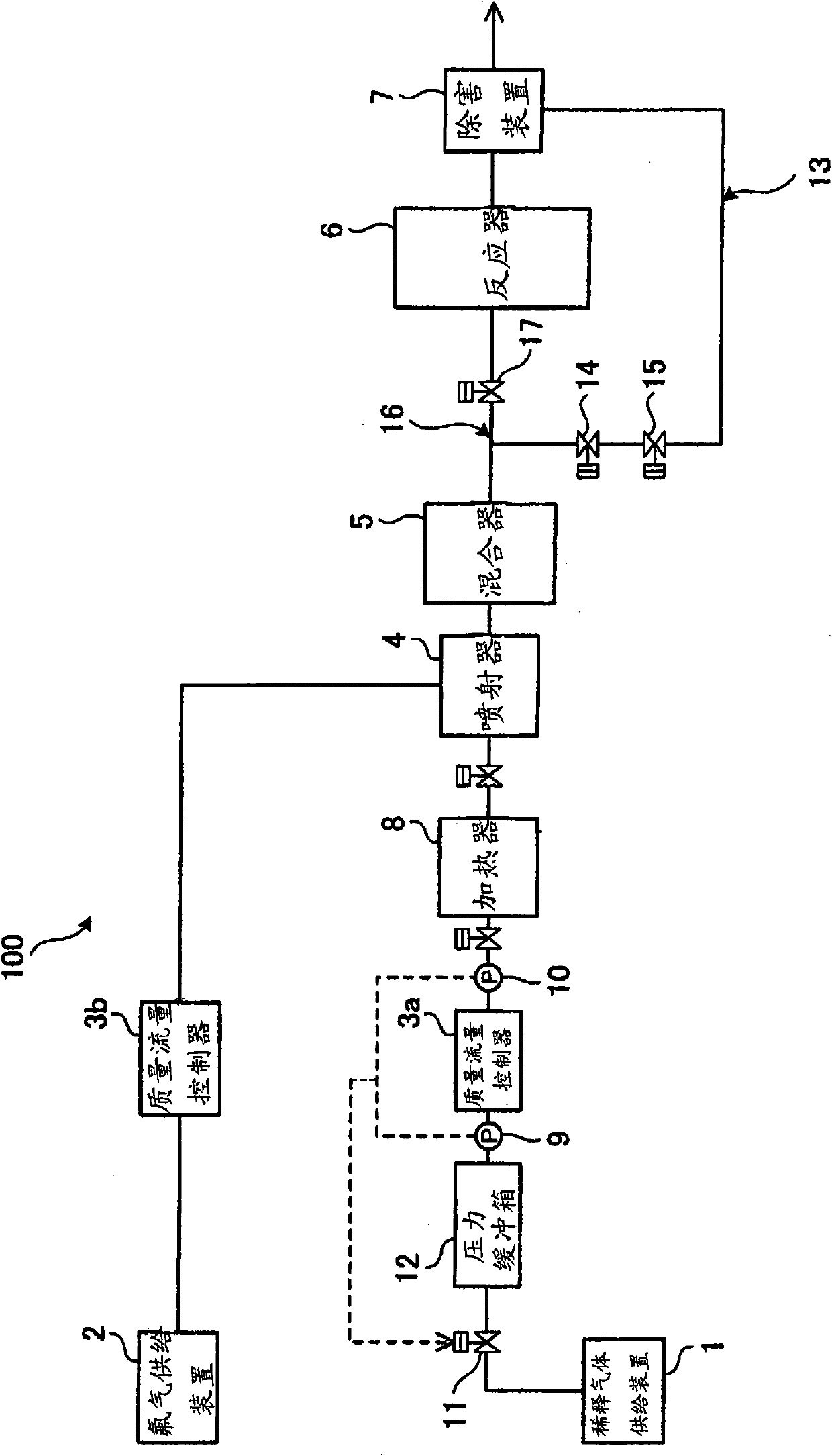

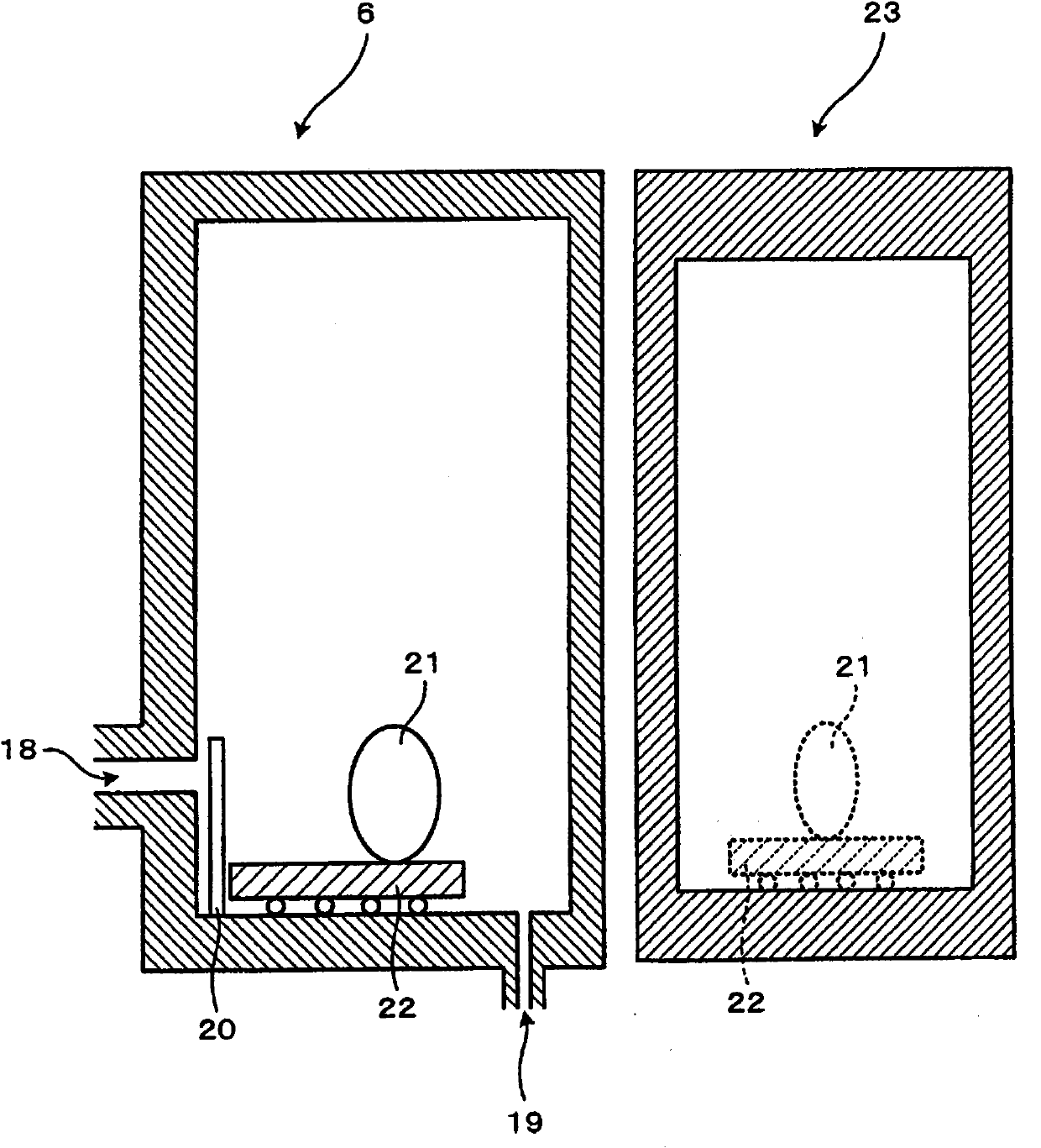

[0068] Here, a first embodiment of the surface treatment device of the present invention will be described. figure 1 It is a schematic configuration diagram of main parts of a surface treatment device according to an embodiment of the present invention, figure 2 yes figure 1 A schematic cross-sectional view of the reactor.

[0069] figure 1 Among them, the surface treatment device 100 includes: a dilution gas supply device 1, a fluorine gas supply device 2, a mass flow controller (first flow rate adjustment mechanism) 3a connected to the dilution gas supply device 1 via piping, and a fluorine gas supply device via piping. Two mass flow controllers (second flow adjustment mechanism) 3b connected to each other are connected to the injector 4 connected to the mass flow controllers 3a and 3b through pipes, respectively, and the injector 4 is connected to the injector 4 through pipes and installed on the downstream side of the injector 4 The mixer 5, the reactor 6 for treating ...

no. 2 Embodiment approach

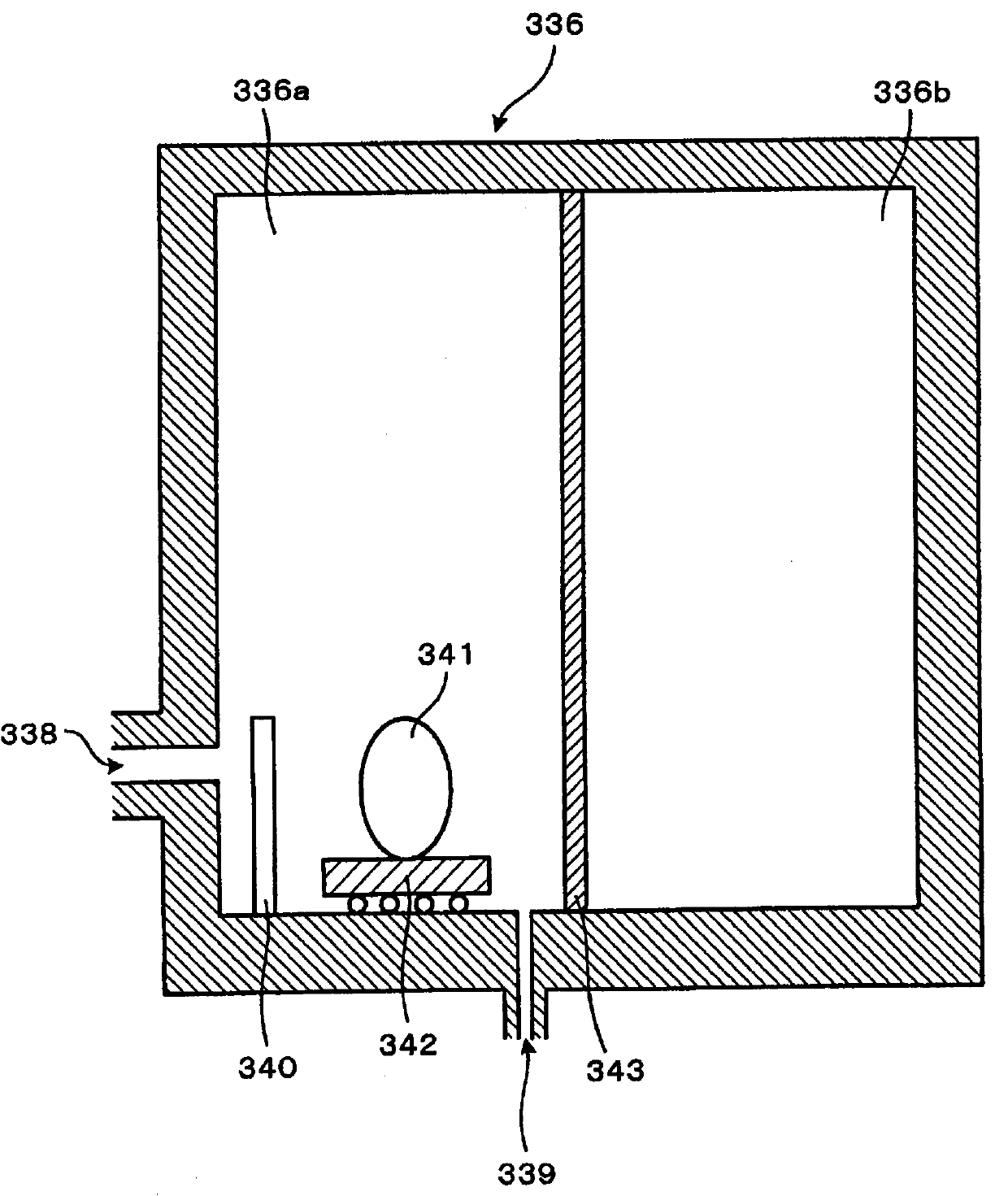

[0107] Here, a second embodiment of the surface treatment device of the present invention will be described. image 3 It is a schematic structural view of the main part of the surface treatment apparatus of 2nd Embodiment. In addition, since the same reference numerals as in the first embodiment are basically the same components as in the first embodiment, description thereof will be omitted.

[0108] image 3 Among them, the surface treatment device 200 includes: a dilution gas supply device 1, a fluorine gas supply device 2, a mass flow controller (first flow adjustment mechanism) 3a connected to the dilution gas supply device 1 via piping, and a fluorine gas supply device via piping. Two mass flow controllers (second flow adjustment mechanism) 3b connected to each other are connected to the injector 4 connected to the mass flow controllers 3a and 3b through pipes, respectively, and the injector 4 is connected to the injector 4 through pipes and installed on the downstream ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com