Method for collecting silicon powder from slurry generated during back lapping process using centrifuge, and centrifuge therefor

A technology of back grinding and centrifuge, which is applied in the direction of centrifuge, centrifuge with rotating drum, silicon, etc., which can solve the problems of low collection performance and low purity of silicon powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

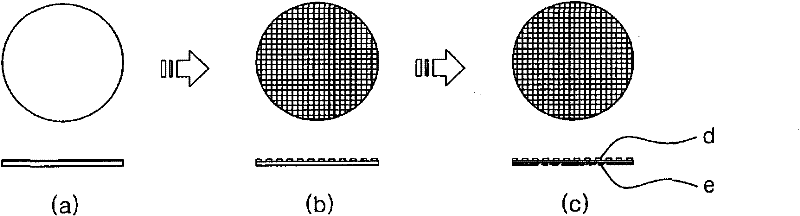

[0055] figure 1 The processing of a semiconductor wafer is illustrated. Such as figure 1 As exemplified in (a), a silicon wafer is produced by cutting a silicon single crystal ingot into a thickness of approximately 600 to 800 μm and grinding one surface thereof into a mirror shape. Such as figure 1 As illustrated in (b), a circuit pattern "d" is formed on the top surface of the wafer. Such as figure 1 As exemplified in (c), by the back grinding process of the post-processing step, the back surface "e" of the wafer having the circuit pattern "d" on its top surface is ground so that the wafer having an initial thickness of about 600˜800 μm is processed into a thickness of approximately 200 μm.

[0056] Semiconductor wafers made by cutting a single crystal silicon ingot have a purity of approximately 99.999999999% (11N). Therefore, when the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com