Curable composition and color filter

A curable composition and compound technology, applied in the field of curable compositions, can solve problems such as surface roughness, insufficient NMP resistance, non-NMP resistance storage stability, etc., achieve high contrast, high NMP tolerance, liquid Good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0360] The components of the following composition were further added to the obtained pigment dispersion liquid 1, and the curable composition (color resist liquid) of this invention was prepared after stirring and mixing.

[0361] ・(B) Alkali-soluble resin: Copolymer of benzyl methacrylate and methacrylic acid (= 70 / 30 [molar ratio]) Weight average molecular weight = 30,000 20.8 parts

[0362] ・(C) Polymeric compound: 20 parts of DPHA manufactured by Nippon Kayaku Co., Ltd.

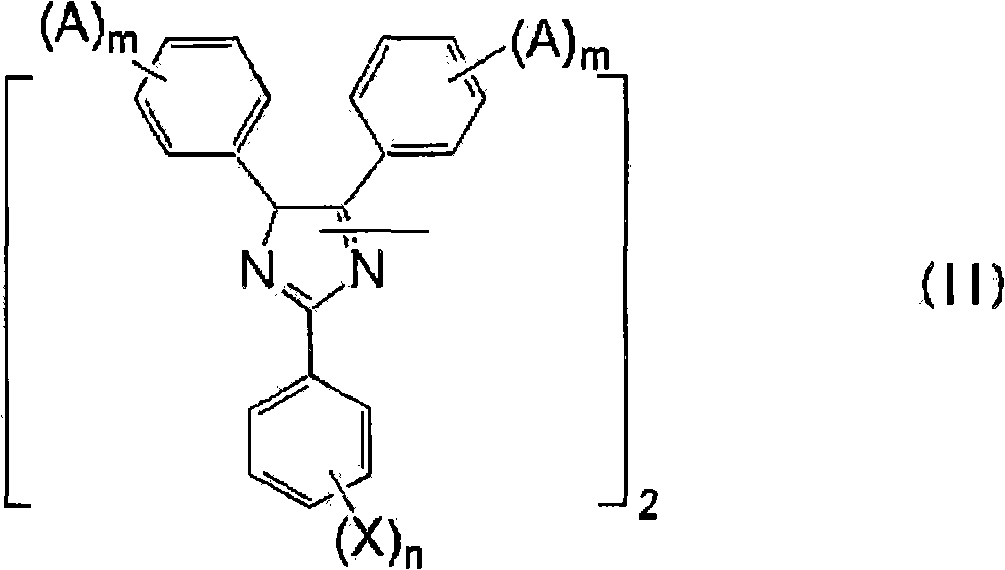

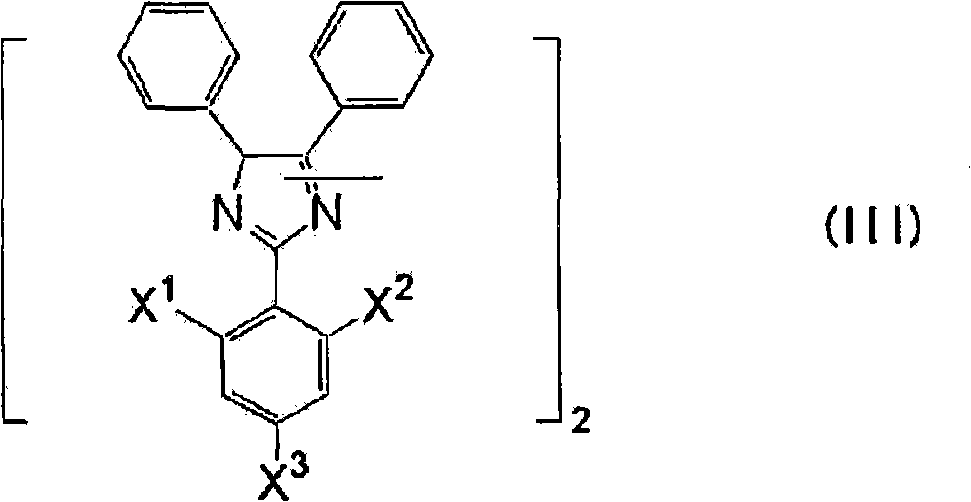

[0363] (D) Polymerization initiator: 3 parts of 2,2'-bis(2-chlorophenyl)-4,4',5,5'-tetraphenylbiimidazole

[0364] (E) Polymerization initiator: 3 parts of 4-[o-bromo-p-N,N-bis(ethoxycarbonyl)aminophenyl]-2,6-bis(trichloromethyl)-s-triazine

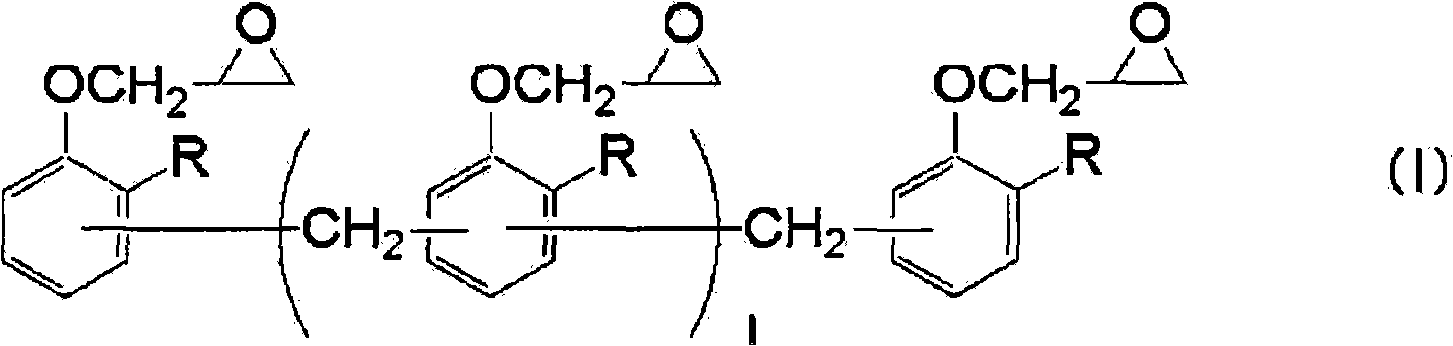

[0365] ・(F) Multifunctional epoxy compound: 5 parts of EPICLON695 manufactured by DIC Corporation

[0366] ·Diethylaminobenzophenone 0.5 parts

[0367] ·N-Phenylmercaptobenzimidazole 0.5 parts

[0368] ・Surfactant: (structure 1 below) 1.0 parts

[0369] 400 par...

Embodiment 2~16 and comparative example 1~6

[0375] In the composition of the curable composition of Example 1, the type and amount of the pigment, the amount of the alkali-soluble resin, the amount of the polymerizable compound, the type and amount of the polymerization initiator, and the amount of the polyfunctional epoxy compound are as follows: 2 was changed to prepare curable compositions of Examples 2-16 and Comparative Examples 1-6.

[0376] [Table 2]

[0377]

[0378] In Table 2, *1 means that the same compound as in Example 1 was used. *2 to *6 are as follows.

[0379] *2: 2,2'-bis(o-chlorophenyl)-4,4',5,5'-tetrakis-(3,4-dimethoxyphenyl)biimidazole

[0380] *3: Ciba Specialty Chemicals Co., Ltd. oxime-based initiator OXE-01 (oxime 1 shown below)

[0381] *4: Oxime 3 (a compound of 5'-2 of the above-mentioned exemplified compounds)

[0382] *5: Oxime 4 (the 5'-3 compound of the above-mentioned exemplified compounds)

[0383] *6: Difunctional epoxy compound EPICLON850-LC manufactured by DIC Corporation

...

Embodiment 33

[0394] In Example 1, (F) polyfunctional epoxy compound EPICLON695 was changed into EHPE-3150 (Daicel Chemical Industry Co., Ltd. polyfunctional epoxy resin) to prepare a curable composition, and it evaluated similarly to Example 1. The results are shown in Table 3.

[0395] Table 3 summarizes the results of the following evaluations using the obtained colored substrates. In addition, curable compositions are used for liquid preservation. All other evaluations were performed using non-TFT color filter substrates.

[0396] 〔NMP tolerance〕

[0397] [Chroma change]

[0398] After measuring the spectral characteristics of each colored substrate with a spectrophotometer MCPD-2000 manufactured by Otsuka Electronics Co., Ltd., each test piece was immersed in a 50° C. NMP (N-methylpyrrolidone) solution for 10 minutes. Next, after rinsing with pure water and drying at 85°C for 60 minutes, the spectral characteristics were measured again, and the degree of chromaticity change by NMP ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com