Process for producing aluminum electrode plate for electrolytic capacitor

A technology of electrolytic capacitor and manufacturing method, applied in the direction of electrolytic capacitor manufacturing, electrolytic capacitor, capacitor electrode, etc., can solve the problems such as the inability to increase the etching rate and the dissolution of the etched part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

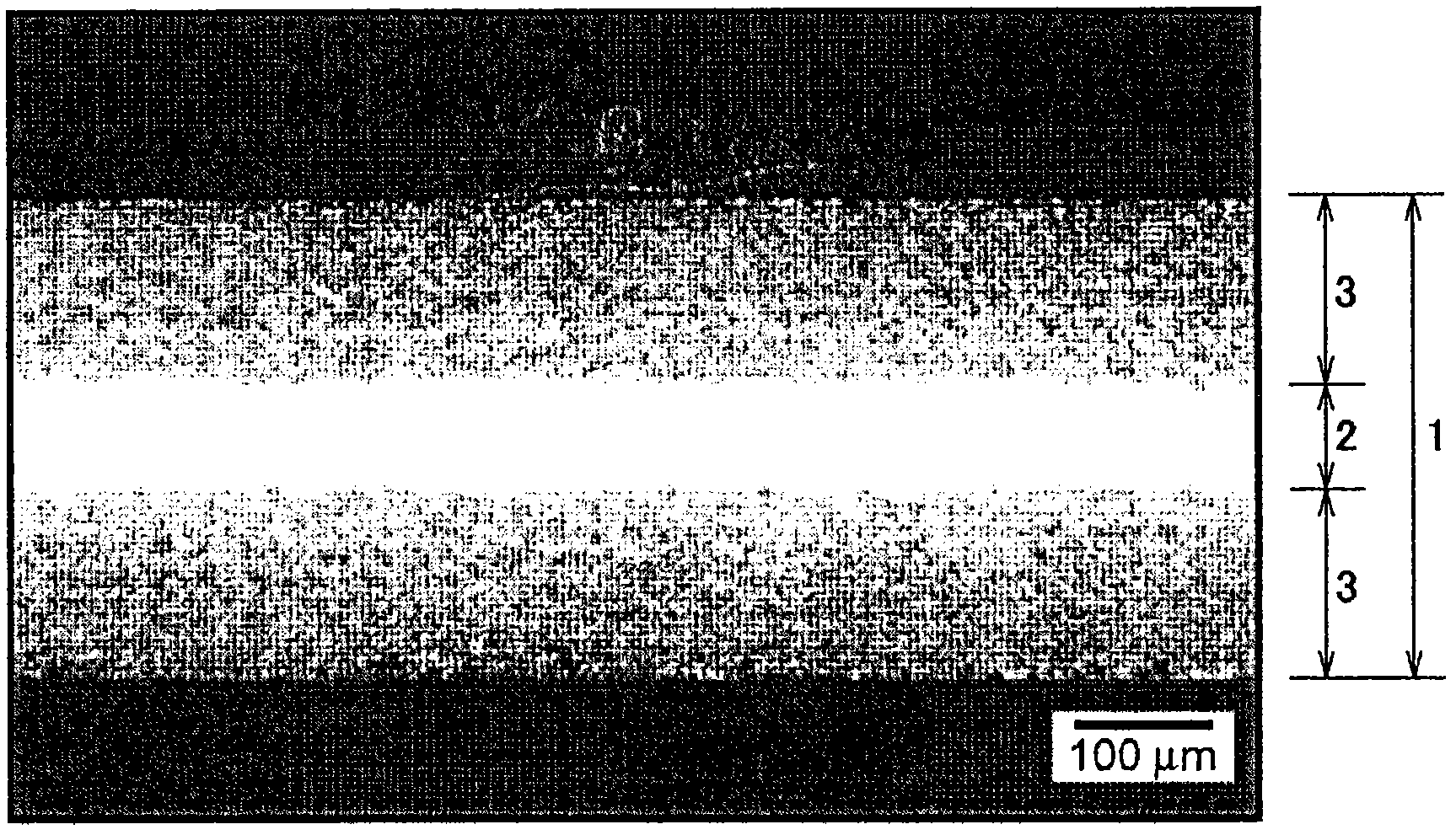

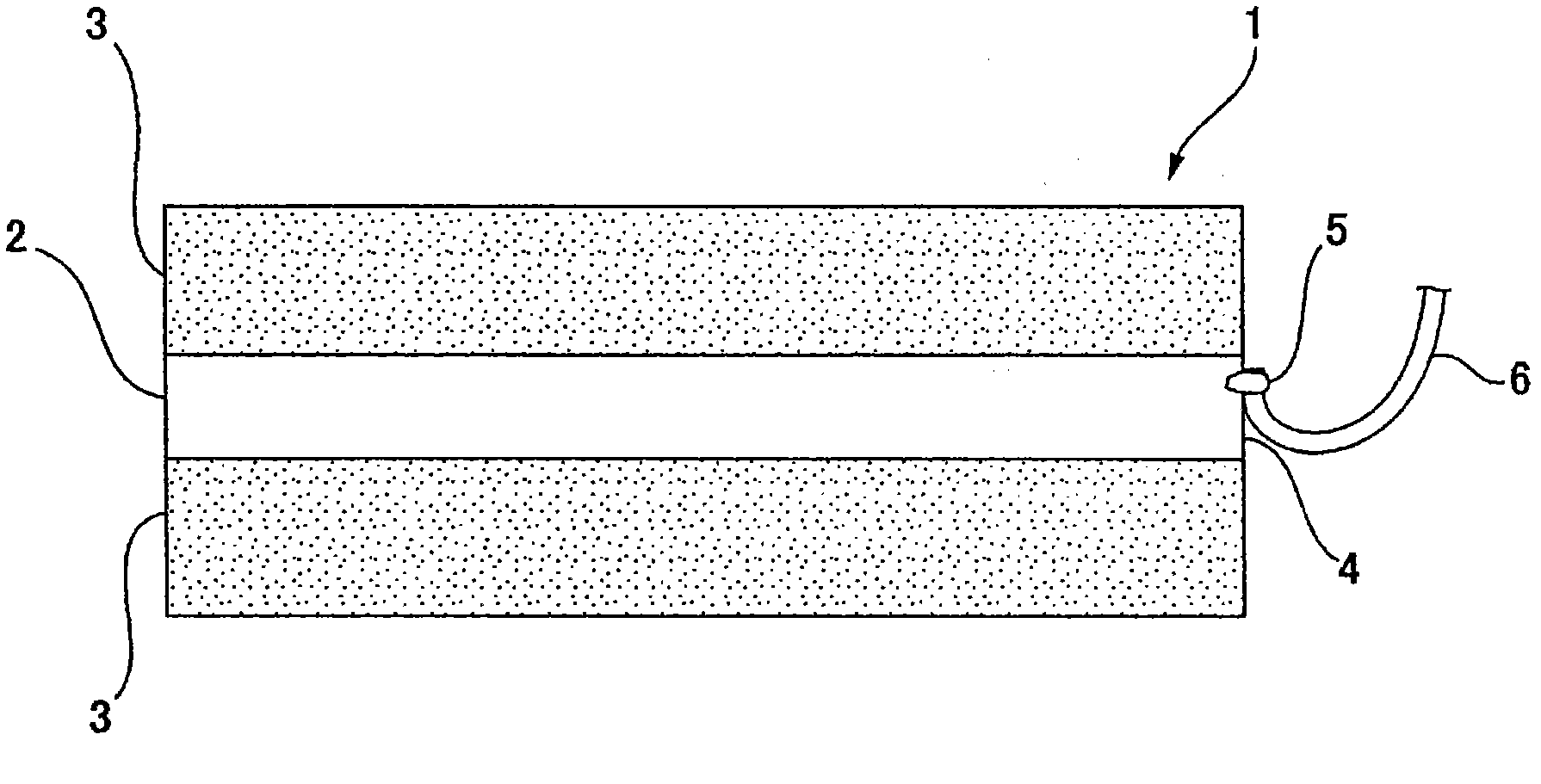

Image

Examples

Embodiment

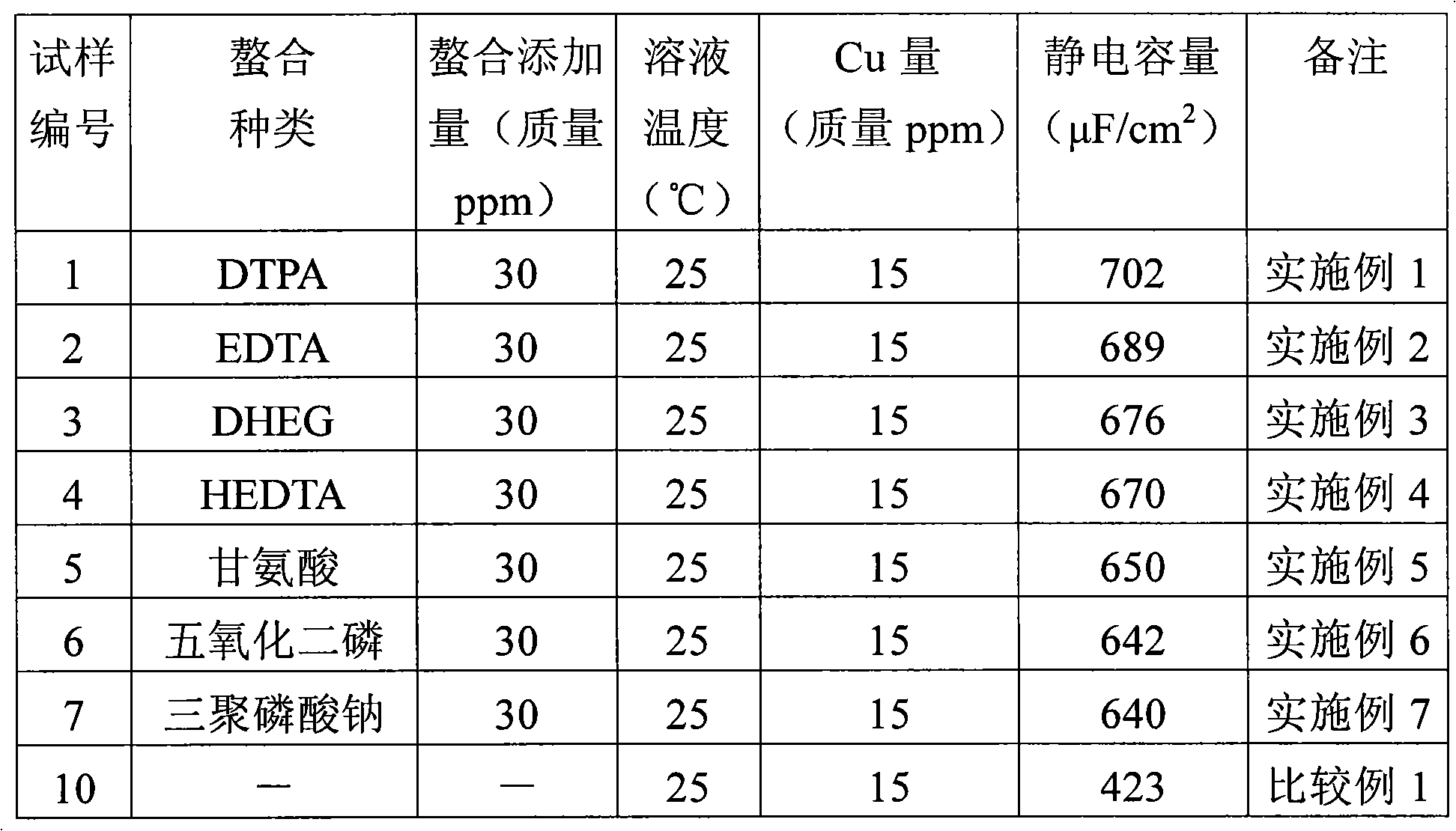

[0040] Next, examples of the present invention will be described.

[0041] (examination result of kind of additive)

[0042] Firstly, the slab with the purity of aluminum above 99.99% by mass, containing 15ppm of copper, 30ppm of iron, 40ppm of silicon, and the rest of other unavoidable impurities undergoes specified rolling to obtain an aluminum plate with a thickness of 0.25mm, and then , Alternating current etching was performed on the aluminum plate under the following conditions to obtain an etched plate.

[0043] First stage etching (first etching process)

[0044] Composition of etching solution: mixed aqueous solution of 3 mol / L hydrochloric acid + 0.5 mol / L sulfuric acid

[0045] Etching solution temperature: 40°C

[0046] Electrolysis waveform: sine wave AC, frequency 50Hz

[0047] Current density: 0.5A / cm 2

[0048] Power: 30C / cm 2

[0049] Second stage etching (Second etching process)

[0050] Composition of etching solution: mixed aqueous solution of 7 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com