Digital doubling and twisting tester

A testing machine and reducer technology, applied in spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of inconvenient testing and research, changing process and production management, and complicated operation, and achieve mechanical transmission. The mechanism is simple, the operation is convenient, and the effect of avoiding fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific example and accompanying drawing thereof, the present invention is described in more detail:

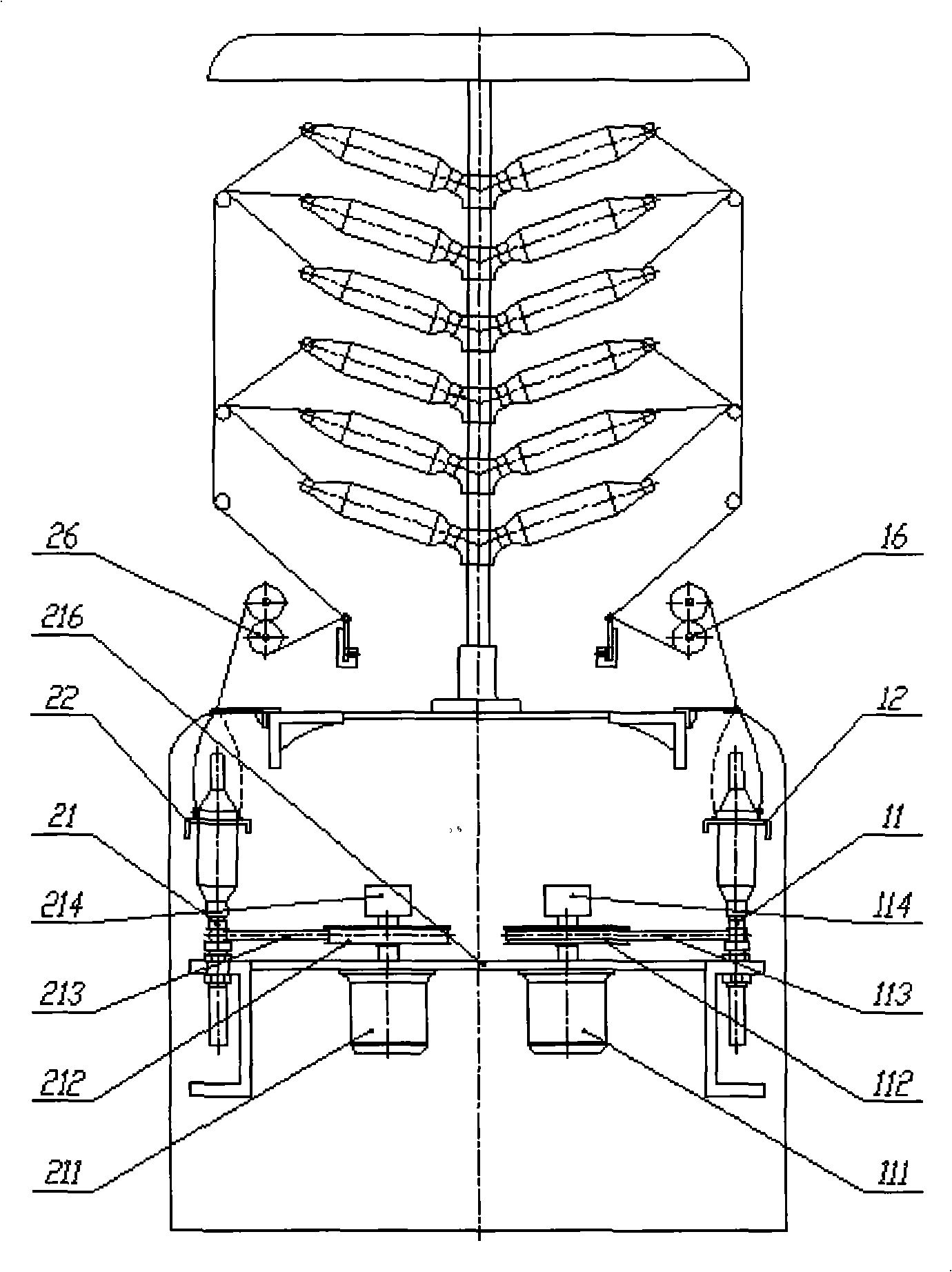

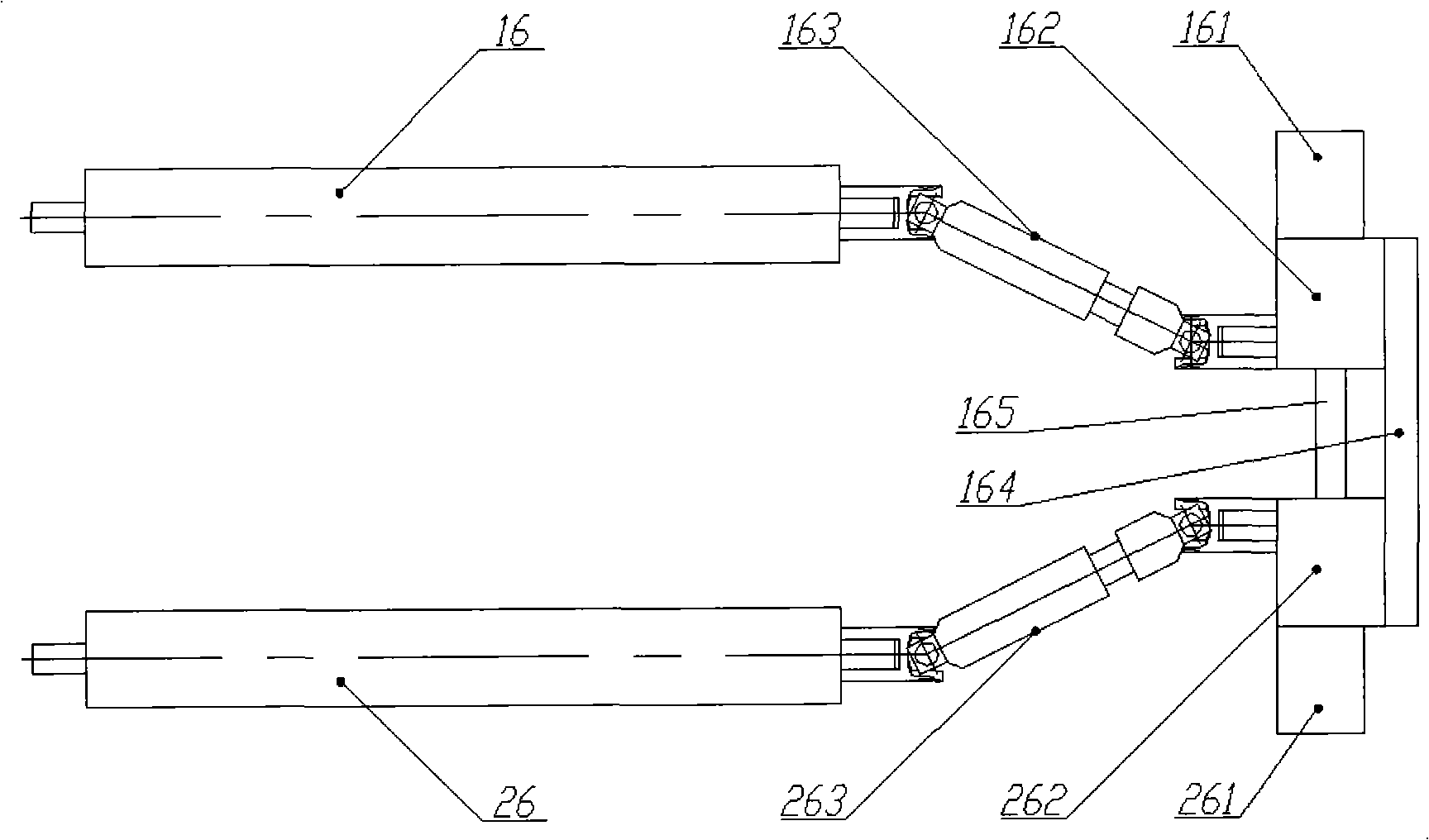

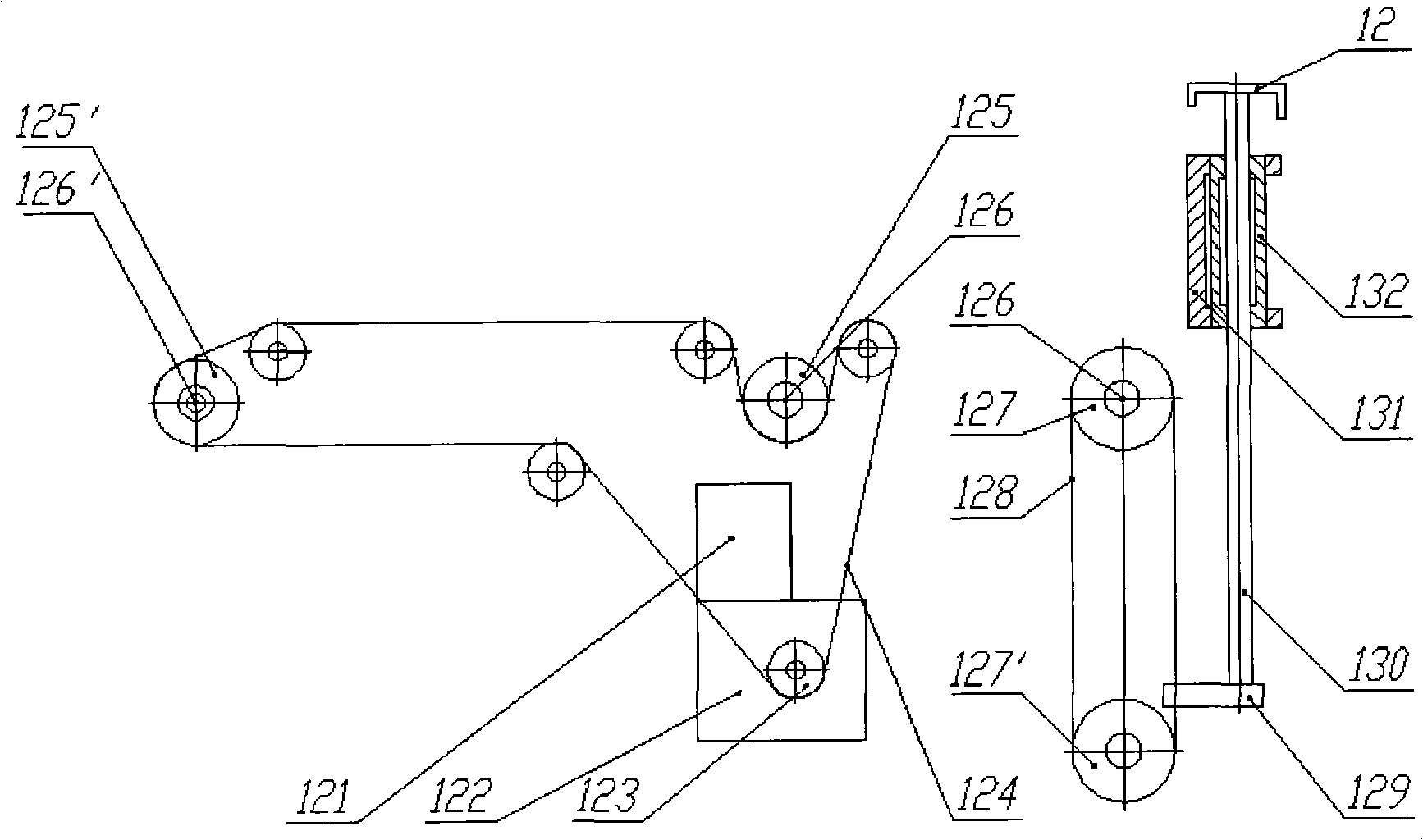

[0014] The digital twisting test machine (hereinafter referred to as the twisting machine for short in the present invention, see Figure 1-5 ), including double-sided symmetrical feeding mechanism, tension mechanism, twisting and winding mechanism, forming mechanism and digital control system with touch screen as interface.

[0015] The twisting machine of the present invention is a two-sided car or a double-sided car, and its cross section is a left-right symmetrical mechanical structure (see figure 1 ), the described feeding mechanism, tension mechanism, twisting winding mechanism and forming mechanism are two sets of mechanisms that are left and right the same.

[0016] The feeding mechanism of the present invention belongs to the prior art, and the yarn enters the tension mechanism after being drawn out by the yarn guide rod.

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com