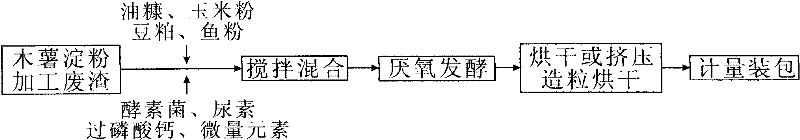

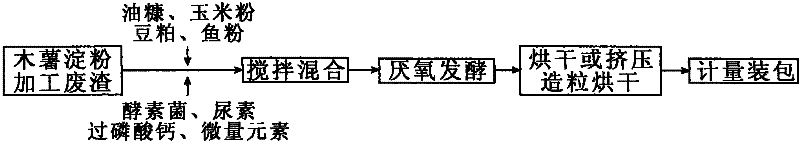

Method for preparing biological feed from arrow root starch processing waste residue

A cassava starch and feed technology, applied in animal feed, animal feed, food processing, etc., can solve the problems of waste of resources, decomposition, low digestion and absorption rate, etc., to reduce production costs and environmental costs, improve absorption rate and effective transformation The effect of increasing the rate, amino acid and lactic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A cassava starch processing enterprise in Guangxi uses the fresh waste residue produced by cassava starch processing to prepare biological feed. The raw materials are formulated according to the following weight percentages: 55% of cassava starch processing waste residue, 20% of oil bran, 8% of corn flour, 12.6% of soybean meal, and 0.1% of enzyme bacteria %, brown sugar 0.2%, fish meal 2%, urea 0.5%, superphosphate 1.5%, salt 0.1%, and copper sulfate, ferrous sulfate and zinc sulfate each 105g / t; mix the above raw materials for 12min, and control the moisture content at 50%, mixed and stacked in strips with a width of 2.0m and a height of 1.5m, and anaerobically fermented for 2 days; dried at 60°C to make powdered feed.

[0016] It is used for experimental breeding of lean-meat pigs, with an average of 2.5-3.0kg per head per day. Under the condition of the same feed cost, pigs can generally gain 5%-10% in weight and 10-15% in income after using this biological feed . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com