Filter for filtering synthetic produced liquid in production process of dimethylformamide and filtering method thereof

A dimethylformamide and production process technology, applied in chemical instruments and methods, filtration loops, filtration separation and other directions, can solve the problems of poor connection status of the outlet of the filter screen, mesh deformation, deformation, etc., to improve the filtration effect, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

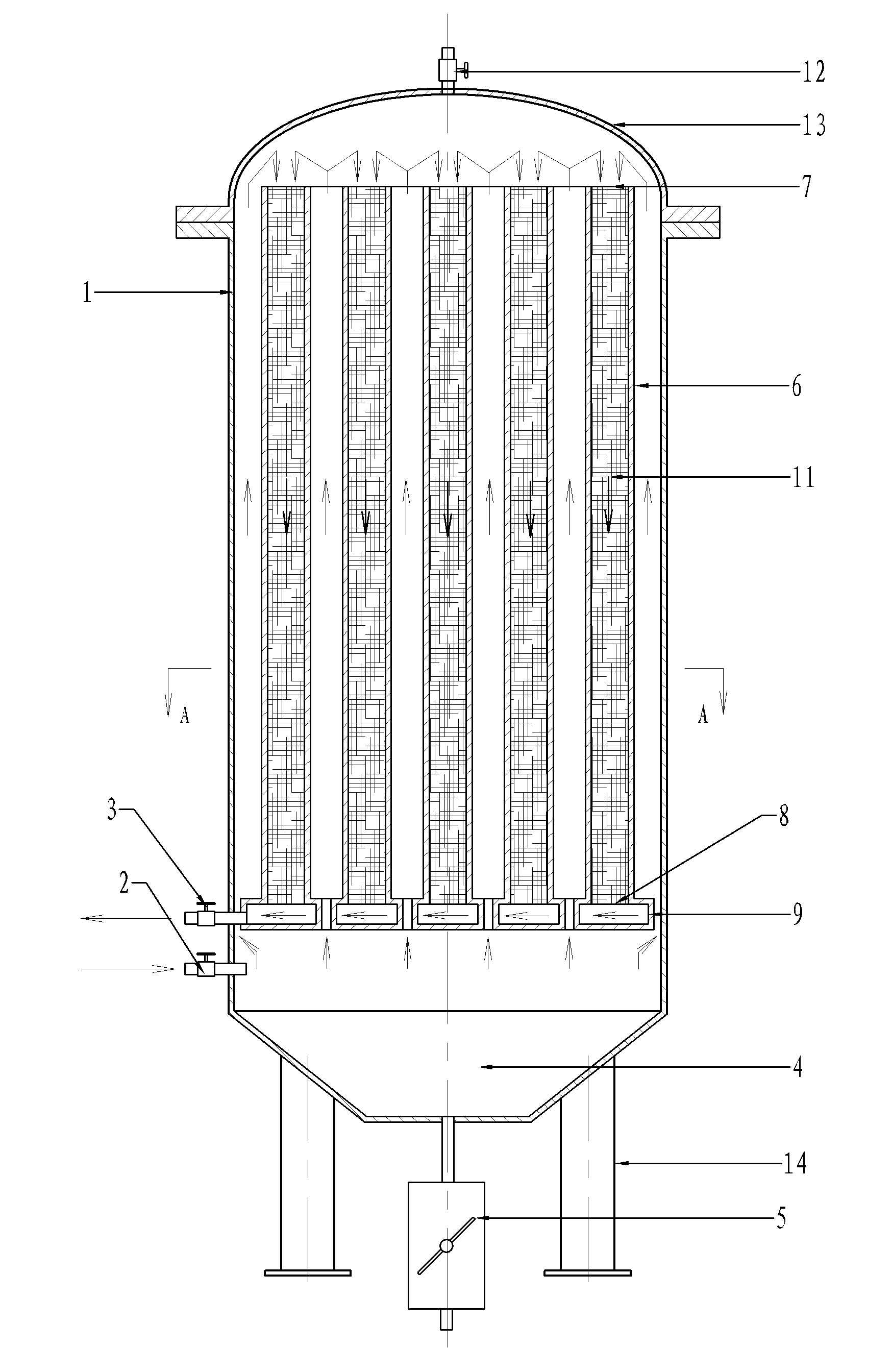

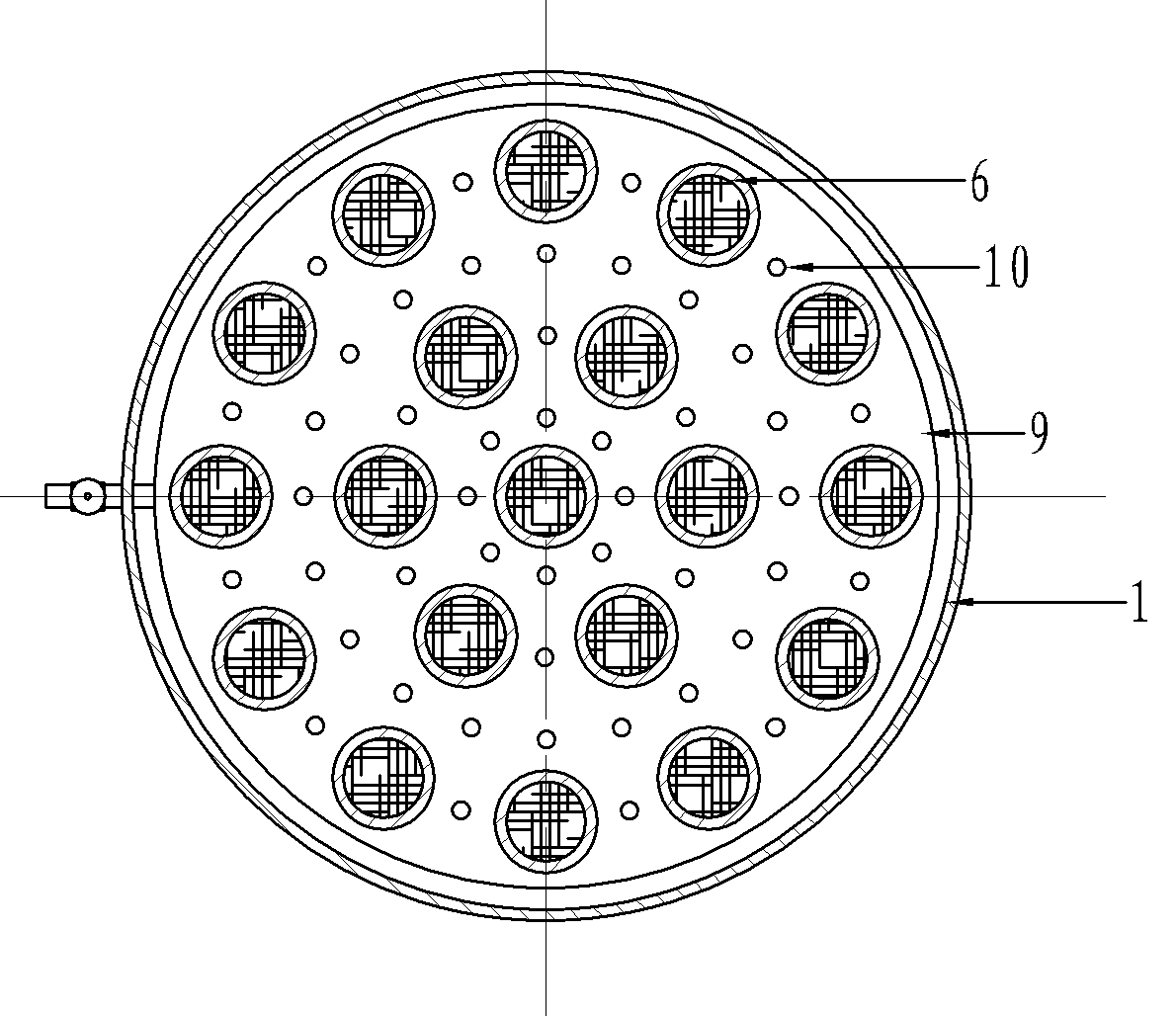

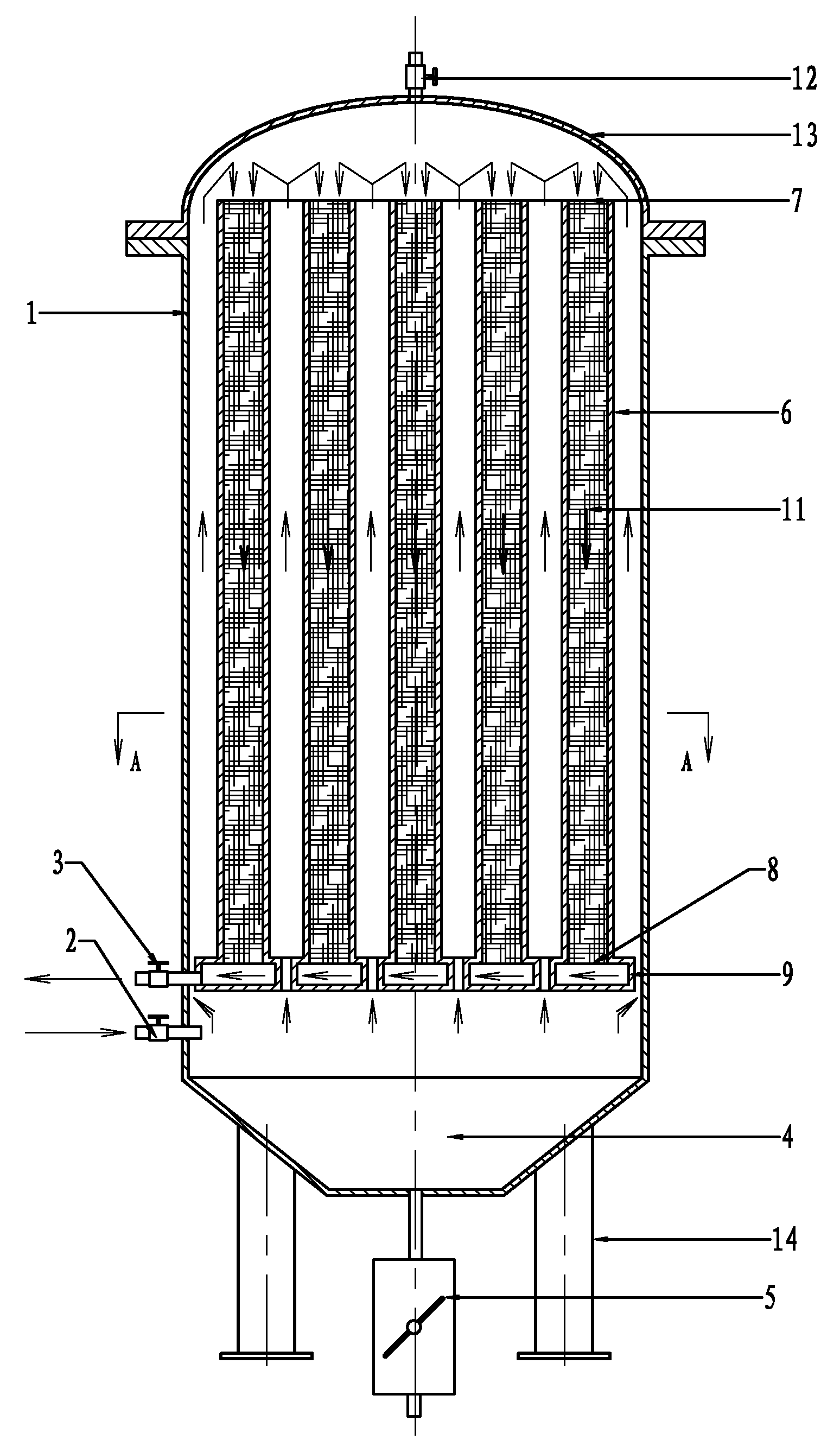

[0017] like figure 1 , 2 As shown, a filter for filtering synthetic production fluid in the production process of dimethylformamide, including a filter cylinder 1, a filter top cover 13, a synthetic production fluid input pipe 2, and a synthetic production fluid output pipe 3 , the bottom of the filter cylinder 1 is a sedimentation chamber 4, the sedimentation chamber 4 is connected to the synthetic production fluid input pipe 2, the bottom of the sedimentation chamber 4 is provided with a sediment discharge valve 5, and four support legs 14 are supported on the filter cylinder 1 At the bottom, the top of the filter top cover 13 is provided with an exhaust port 12, the filter cylinder 1 and the filter pipe 6 are made of stainless steel, and more than one vertically placed filter pipe 6 is installed inside the filter cylinder 1, The upper end of the filter tube 6 is the filter tube inlet port 7, the lower end of the filter tube 6 is the filter tube outlet port 8, the filter tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com