Method for manufacturing high-quality bamboo plywood template by utilizing bamboo wood efficiently

A processing method and template technology, applied in the direction of manufacturing tools, wood processing utensils, and the joining of wooden veneers, can solve the problems of difficult quality control and low utilization rate of bamboo materials, improve the utilization rate, and facilitate recycling and reuse. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

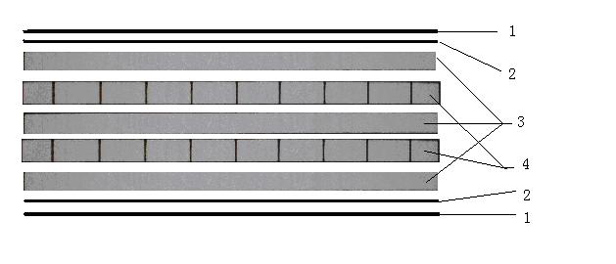

Image

Examples

Embodiment 1

[0043] A kind of concrete steps of the processing method of efficiently utilizing bamboo to manufacture high-quality bamboo glued formwork are:

[0044] Step 1: harvest fresh moso bamboo, remove sundries on the bamboo trunk, cut off the moso bamboo from the end of the root, and then cut straight moso bamboo sections with a length of 1.3 meters and 2.6 meters according to the curved shape and taper of the moso bamboo, and set them aside;

[0045] Step 2: Use the bamboo tube to remove the outer section equipment to remove the outer section of the bamboo section; select the number of cutting heads according to the diameter of the front end of the bamboo section, so that the opened bamboo pieces are as flat as possible, with a width of 15mm; use the bamboo slice to remove the inner section equipment to remove the inner section of the bamboo slice;

[0046] Step 3: Send the bamboo chips with two lengths of 1.3 meters and 2.6 meters from the inner section to the crushing machine for...

Embodiment 2

[0056] A kind of concrete steps of the processing method of efficiently utilizing bamboo to manufacture high-quality bamboo glued formwork are:

[0057] Step 1: Harvest fresh moso bamboo, remove the sundries on the bamboo trunk, choose moso bamboo that is 6 years old, and have a non-defective moso bamboo with a diameter of more than 10 cm; cut off the moso bamboo from the end of the root, and then divide the moso bamboo according to the curved shape and taper of the moso bamboo. Cut straight moso bamboo sections with a length of 1.3 meters and 2.6 meters for use;

[0058] Step 2: Use the bamboo tube to remove the outer section equipment to remove the outer section of the bamboo section; select the number of cutting heads according to the diameter of the front end of the bamboo section, so that the opened bamboo pieces are as flat as possible, with a width of Between 40mm; use the bamboo chip to remove the inner section equipment to remove the inner section of the bamboo chip; ...

Embodiment 3

[0069] A kind of concrete steps of the processing method of efficiently utilizing bamboo to manufacture high-quality bamboo glued formwork are:

[0070] Step 1: harvest fresh moso bamboo, remove sundries on the bamboo trunk, select moso bamboo that is 3 years old and have a non-defective moso bamboo with a diameter of more than 10 cm; cut off the moso bamboo from the end of the root, and then divide the moso bamboo according to the curved shape and taper of the moso bamboo Cut straight moso bamboo sections with a length of 1.3 meters and 2.6 meters for use;

[0071] Step 2: Use the bamboo tube to remove the outer section equipment to remove the outer section of the bamboo section; select the number of cutting heads according to the diameter of the front end of the bamboo section, so that the opened bamboo pieces are as flat as possible, with a width of 30mm; use the bamboo slice to remove the inner section equipment to remove the inner section of the bamboo slice;

[0072] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com