Low whitening alpha-cyanoacrylate adhesive

A cyanoacrylate and adhesive technology, which is applied in adhesives, non-polymer organic compound adhesives, non-polymer adhesive additives, etc., can solve problems affecting the scope of use, and achieve the effect of reducing whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

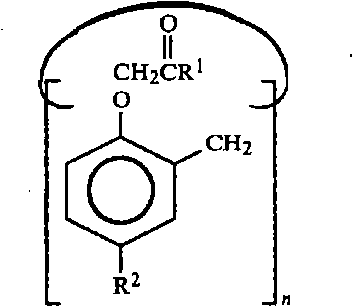

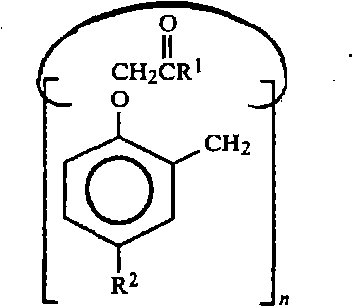

Image

Examples

Embodiment 1

[0016] Alpha-cyanoacrylate selects alpha-cyanoacrylate ethyl ester, calixarene selects 4-p-tert-butylcalix[8]arene octaethyl acetate, anionic polymerization inhibitor selects p-toluenesulfonic acid, free radical polymerization inhibitor Use hydroquinone. Put ethyl alpha-cyanoacrylate into a three-necked flask, and add 4-p-tert-butylcalix[8]arene 8, which accounts for 2% of the weight of ethyl alpha-cyanoacrylate, to ethyl alpha-cyanoacrylate. The low-whitening α-cyanoacrylate adhesive can be prepared by mixing octaethyl acetate, 200ppm p-toluenesulfonic acid and 1000ppm hydroquinone evenly at room temperature.

[0017] The curing speed, 24h shear strength and whitening data measured by Example 1 are shown in the following table:

[0018] Test 1: 2% 4-tert-butylcalix[4]arene-tetraethyl acetate

[0019] Test 2; without 4-tert-butylcalix[4]arene-tetraethyl acetate

[0020] Test 3: 7% 4-tert-butylcalix[4]arene-tetraethyl acetate

[0021]

Embodiment 2

[0023] α-cyanoacrylate is selected from α-cyanoacrylate, calixarene is selected from 4-tert-butyl calix[4]arene-tetraethyl acetate, anionic polymerization inhibitor is selected from methanesulfonic acid, and free radical polymerization inhibitor is selected from paracetamol. Methoxyphenol. Put α-cyanopropyl acrylate into a three-necked flask, and add [4] aromatic hydrocarbon-tetraethyl acetate, 150 ppm methyl ethyl acetate, 0.7% by weight of α-cyano ethyl acrylate to α-cyano propyl acrylate. Sulfuric acid and 800ppm of p-methoxyphenol can be made into low-whitening α-cyanoacrylate adhesive by stirring evenly at room temperature.

[0024] The curing speed, 24h shear strength and whitening data measured by Example 2 are shown in the following table:

[0025] Test 1: 0.7% 4-p-tert-butylcalix[8]arene octaethyl acetate

[0026] Test 2; without 4-p-tert-butylcalix[8]arene octaethyl acetate

[0027] Test 3: 0.1% 4-p-tert-butylcalix[8]arene octaethyl acetate

[0028]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com