Packing fluid for branch well drilling

A technology of filling liquid and micelles, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of easy adsorption, oil flow obstruction, oil well productivity decline, etc., achieve strong suspension ability and improve oil well productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the preparation of the filling liquid that is made up of water, micelle viscosifier and fluid loss reducer

[0020] In 300 ml of Bohai sea water, add 3 grams of N, N'-bis(hexadecyldimethyl)-1,3-dipropylene diammonium bromide and 6 grams of N, N'-bis(dodecyl Alkyl dimethyl)-1,2-ethylene diammonium bromide was stirred for 20 minutes with a speed of 10000r / min on a high stirrer to make it dissolve completely, then add 6 grams of emulsified paraffin (Hubei Hanke New Technology Co., Ltd. Co., Ltd., code-named HFL), stirred for 10 minutes to obtain a filling solution composed of water, surfactant and emulsified paraffin, wherein the mass-number ratio of water, surfactant and emulsified paraffin was 100:3:2. Among them, the surfactant is N, N'-bis(hexadecyldimethyl)-1,3-dibromide propylene diammonium salt and N,N'-bis(dodecyldimethyl)- 1,2-dibromide ethylenediammonium salt, the mass-to-number ratio is 1:2.

Embodiment 2

[0021] Embodiment 2, the preparation of the filling liquid that is made up of water, micellar viscosifier and fluid loss reducer

[0022] In 300 ml of fresh water, add 9 grams of N,N'-bis(tetradecyldimethyl)-1,3-dipropylene diammonium bromide and 3 grams of N,N'-bis(hexadecane Dimethyl)-1,3-propylene diammonium bromide was stirred for 20 minutes at a speed of 10000r / min on a high stirrer to make it completely dissolved, and then added 9 grams of 3-chloro-2-hydroxypropyl Trimethylammonium chloride etherified starch (Hubei Hanke New Technology Co., Ltd., code name HFD), stirred for 10 minutes to obtain a filling solution composed of water, surfactant and cationic starch, wherein water, surfactant and The mass-to-number ratio of the cationic starch is 100:4:3. Among them, the surfactant is N, N'-bis(tetradecyldimethyl)-1,3-dibromide propylene diammonium salt and N,N'-bis(hexadecyldimethyl)- 1,3-dibromide propylene diammonium salt, the mass-to-number ratio is 3:1.

Embodiment 3

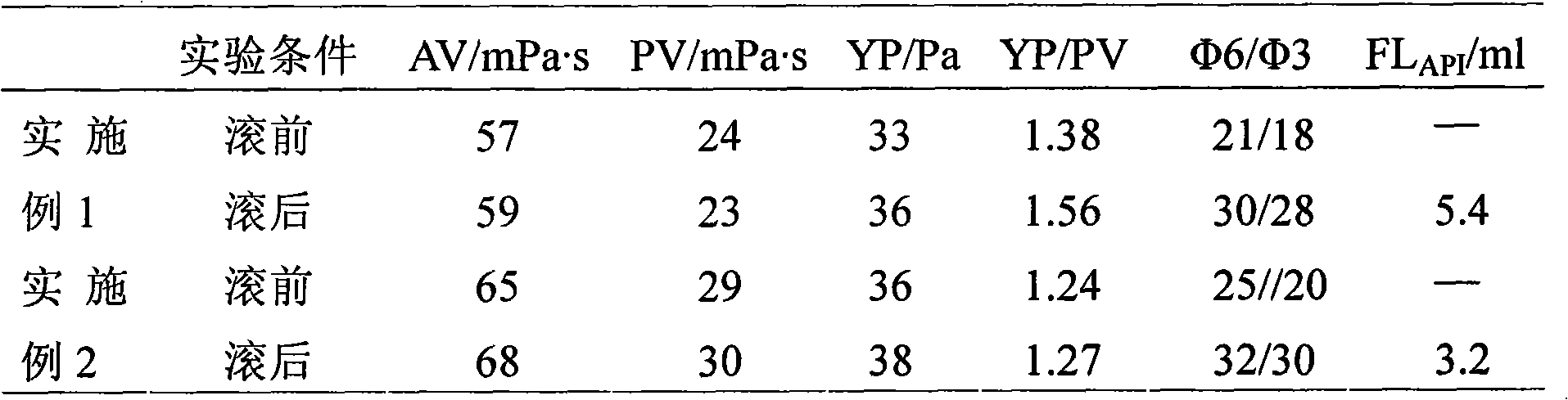

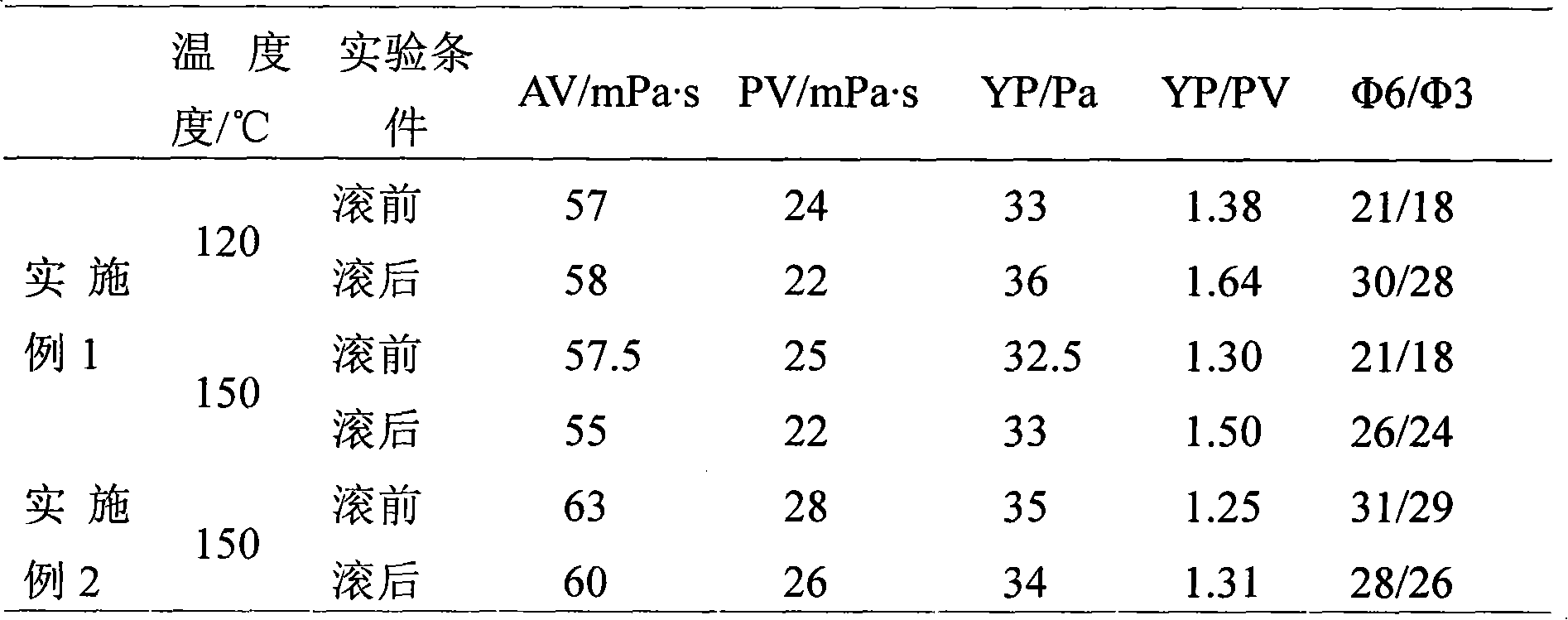

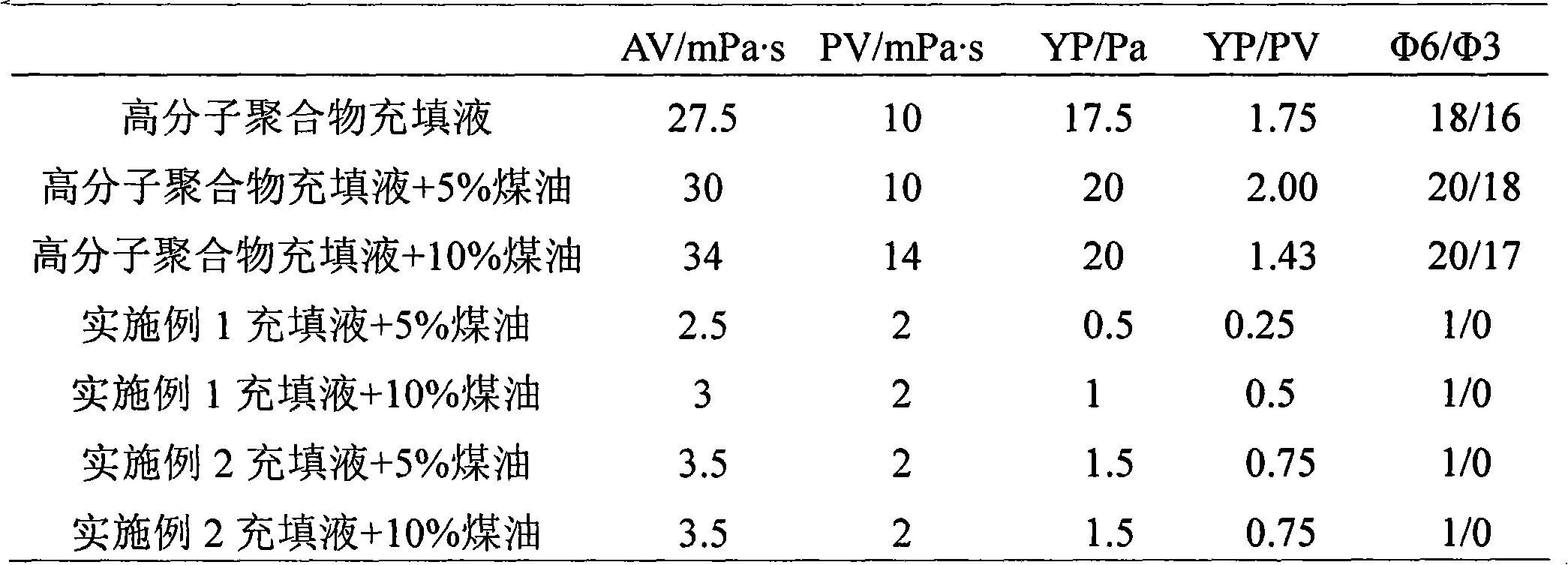

[0023] Performance evaluation of embodiment 3, embodiment 1 and embodiment 2 filling liquid

[0024] (1) Rheology and fluid loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com