Airbag shell inflatable suspension proppant and preparation method thereof

The technology of proppant and airbag shell is applied in the field of inflatable suspension proppant of airbag shell and its preparation, which can solve the problems of high construction cost, loss of self-suspending ability of proppant, etc. Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

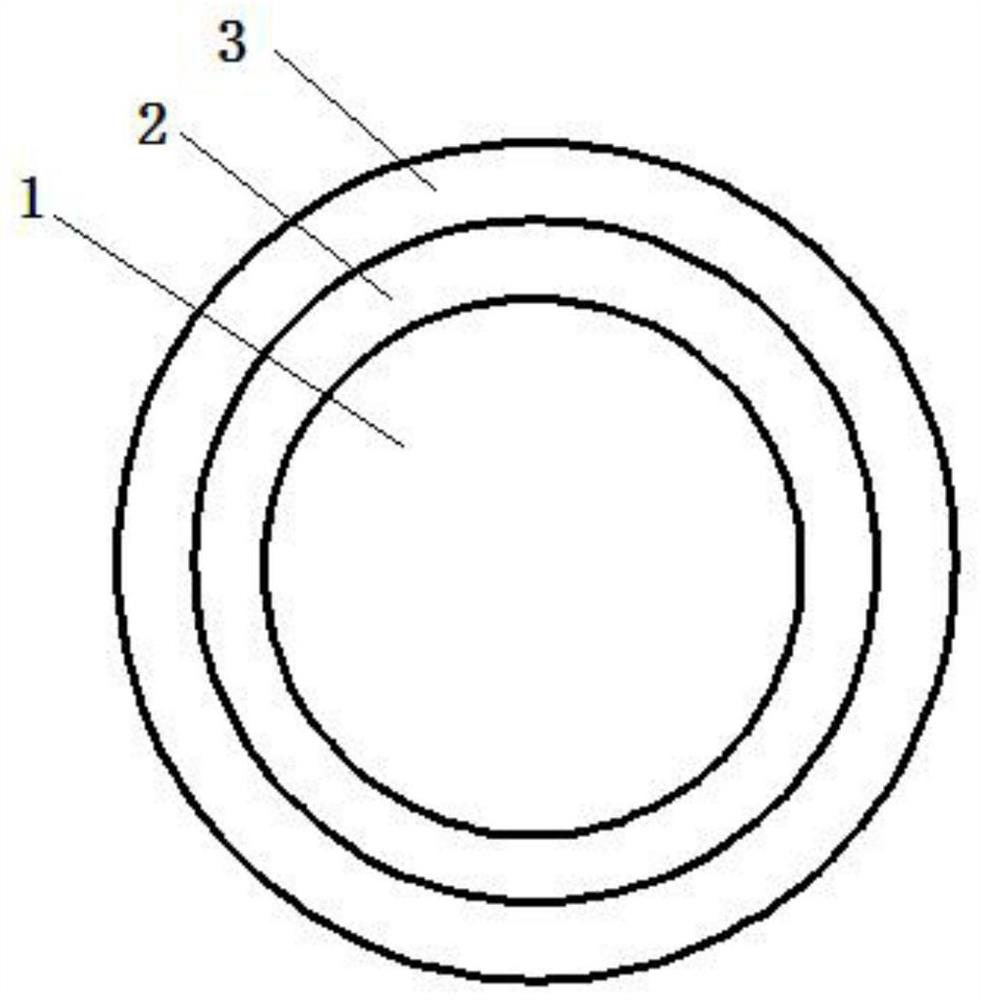

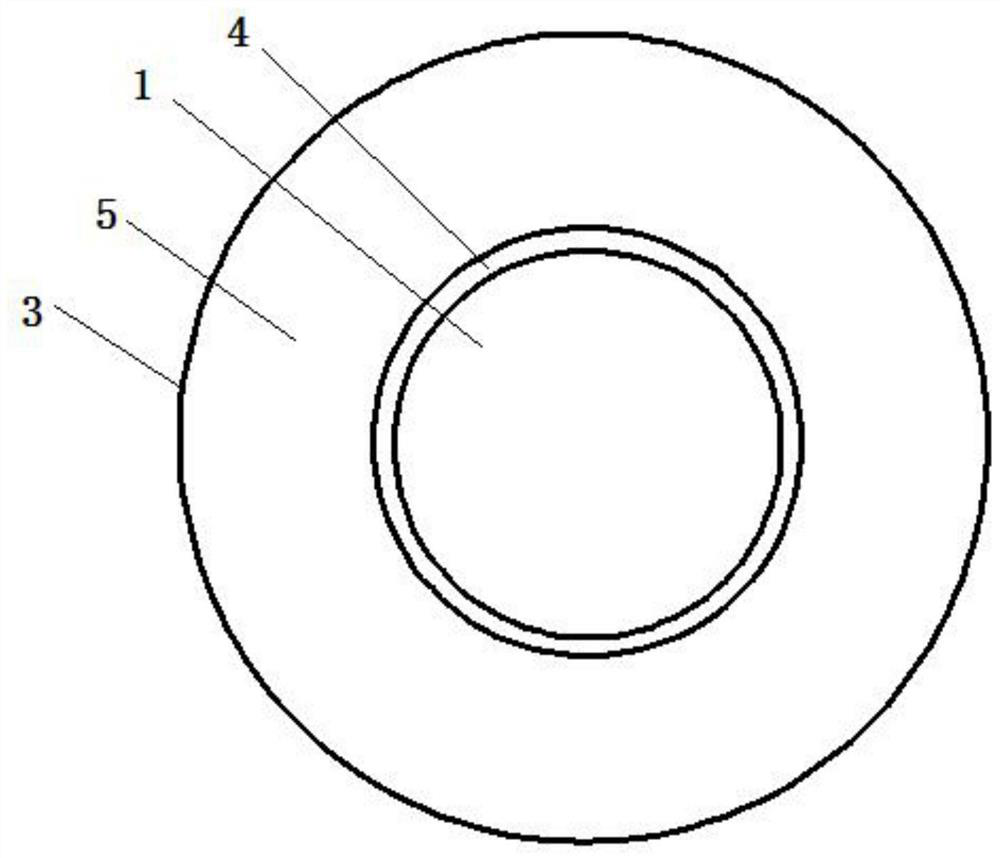

[0026] A kind of preparation process of air bag shell inflatable suspension proppant:

[0027] Step 1: Dissolve 0.02g glyceryl tripalmitate, 0.03g acrylic acid, and 0.05g polyurethane in 5mL petroleum ether, then atomize and spray the petroleum ether solution onto the surface of 100g quartz sand proppant, and the particle size range of quartz sand is 40 -70 mesh;

[0028] Step 2: Physically stir and mix the proppant obtained in step 1 with 0.06g sodium carbonate, 0.04g citric acid, 0.1g ammonium chloride, and 0.1g sodium nitrite powder, and use an adhesive to bond the gasifying agent powder to the proppant surface;

[0029] Step 3: Mix 0.1g polyethylene glycol diacrylate, 0.3g tert-butyl acrylate, 0.002g organic nano-montmorillonite and 2mL white oil evenly, mix 0.005g initiator with 1.5mL white oil, and the initiator It is a mixture of dibenzoyl peroxide and N,N-dimethylaniline (molar ratio 2:1), atomize and spray the white oil containing the shell agent and the shell enhan...

Embodiment 2

[0031] A preparation process of an airbag shell inflatable suspension proppant:

[0032] Step 1: Dissolve 0.01g of cetyl acetyl octaester, 0.1g of epoxy resin, and 0.05g of ethylenediamine in 5mL of acetone, and then atomize and spray the acetone solution onto the surface of 100g of quartz sand proppant. The range is 20-40 mesh;

[0033] Step 2: Physically stir and mix the proppant obtained in step 1 with 0.12g sodium carbonate, 0.08g citric acid, 0.3g ammonium chloride, and 0.3g sodium nitrite powder, and use an adhesive to bond the gasifying agent powder to the proppant surface;

[0034] Step 3: Mix 0.1g polyethylene glycol diacrylate, 0.8g tert-butyl acrylate, 0.1g styrene, 0.005g carbon nanotubes with 5mL kerosene, mix 0.01g initiator with 3.0mL kerosene, and initiate The agent is a mixture of dibenzoyl peroxide and N,N-dimethylaniline (molar ratio 2:1), and the kerosene containing the capsule shell agent and the capsule shell enhancer and the kerosene containing the ini...

Embodiment 3

[0036] A preparation process of an airbag shell inflatable suspension proppant:

[0037] Step 1: Dissolve 0.03g of pentaerythritol tetra(stearate), 0.2g of epoxy resin, and 0.1g of m-phenylenediamine in 5mL of toluene, and then atomize and spray the toluene solution onto the surface of 100g of ceramsite proppant. The particle size range is 20-40 mesh;

[0038] Step 2: Physically stir and mix the proppant obtained in step 1 with 0.25g urea, 0.2g oxalic acid, 0.37g sodium carbonate, and 0.5g sodium nitrite powder, and use an adhesive to bond the gasifying agent powder to the surface of the proppant;

[0039] Step 3: Mix 0.25g polyethylene glycol dimethacrylate, 1.0g tert-butyl acrylate, 0.55 butyl methacrylate, 0.018g nano-silicon dioxide and 7mL diesel oil, mix 0.02g initiator with 4.0mL The diesel oil is mixed evenly, the initiator is a mixture of dibenzoyl peroxide and N,N-dimethylaniline (molar ratio 2:1), the diesel oil containing the capsule shell agent and the capsule shel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com