High-grade highway structure of soaked sand dredger filling embankment in coastal region

A high-grade dredging sand filling technology, applied in roads, roads, buildings, etc., can solve the problems of high cost, long cycle, poor stability, etc., achieve the effect of reducing direct investment, improving comprehensive road performance, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

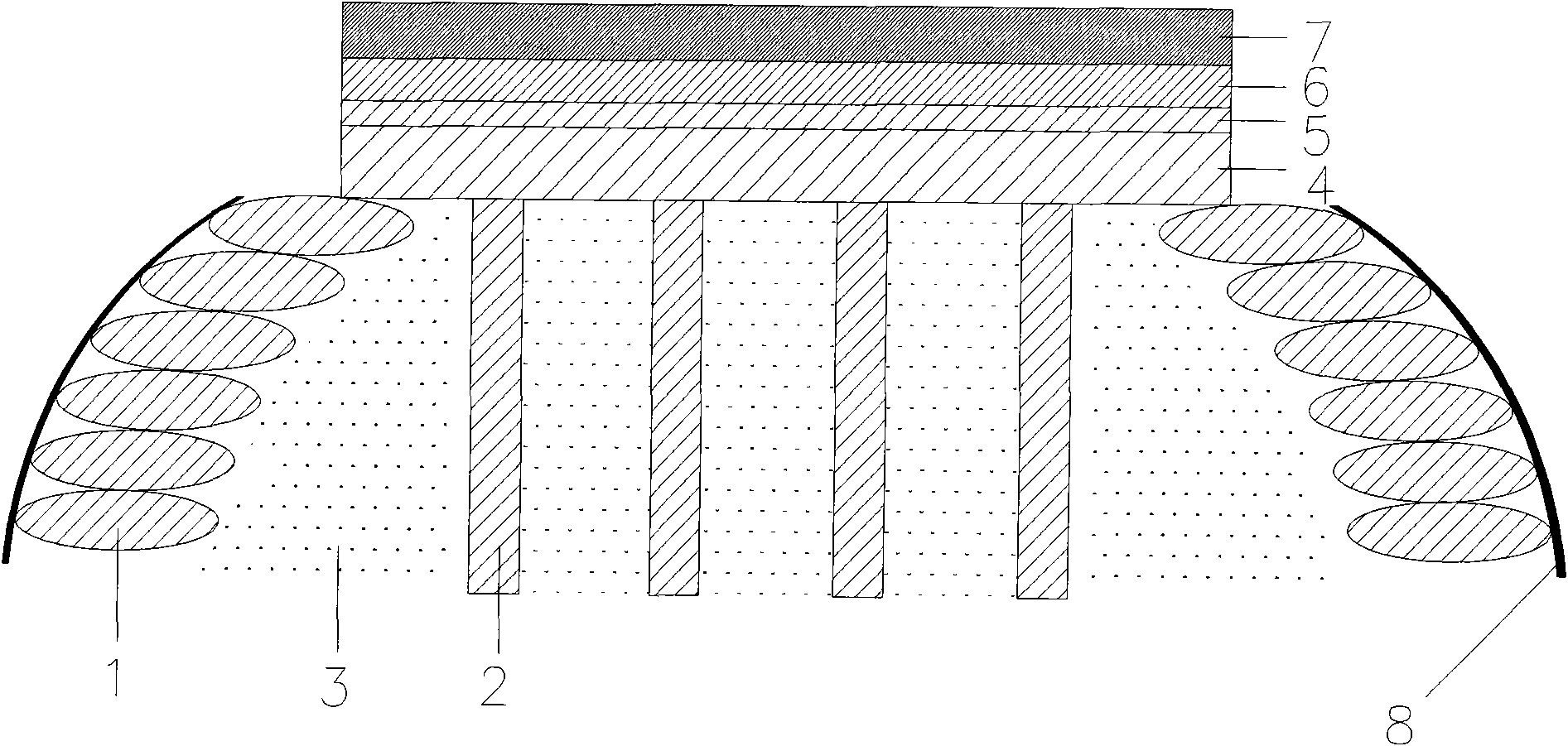

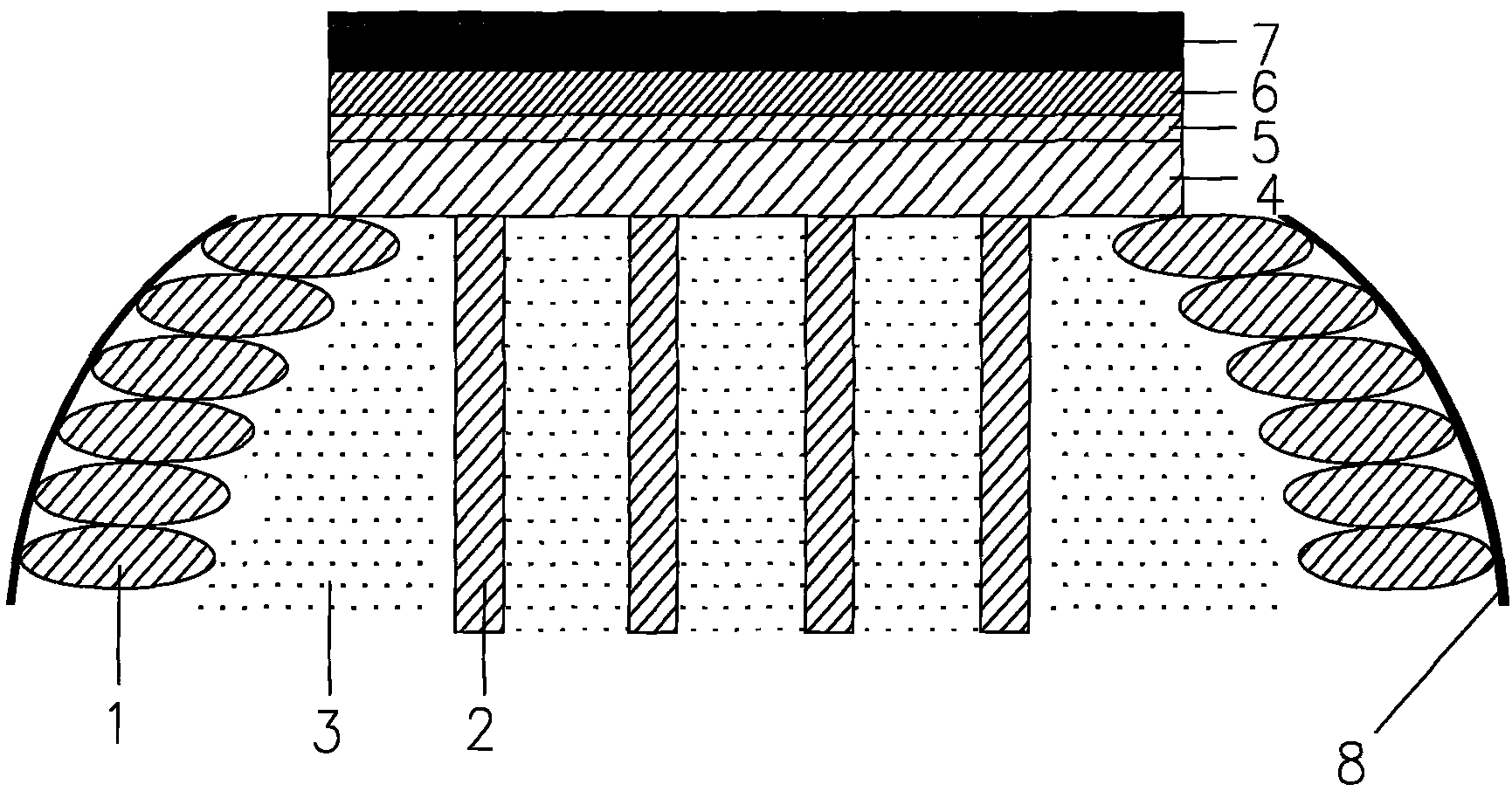

[0012] The specific technical characteristics are as follows:

[0013] 1. The bagged sand cofferdam 1, the anti-seepage protective layer outside the cofferdam 8, the dredged sand inside the cofferdam 3, the pile foundation in the dredged sand 2, the mountain stone layer 4, the solidified mud sand layer 5, cement The stable crushed stone layer 6 and the asphalt concrete layer 7 are formed.

[0014] 2. The bagged sand cofferdam 1 is built on both sides of the road bed, and waterproof and moisture-proof measures such as anti-seepage geotextile, molded bag concrete and embankment stone slope protection are adopted outside the cofferdam 8 .

[0015] 3. The height of the cofferdam is marked as the top surface of the lower road bed; the interior of the cofferdam uses dredging sand 3, the maximum particle size of the dredged sand is required to be less than 0.5mm, and the mud content is not more than 10%. The height of the cofferdam is equal to or not less than 0.5 meters.

[0016] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com