Large-torque driving device of engine

A transmission device, high torque technology, applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve the problems of not being able to install an air compressor, the transmission torque is not enough to meet the requirements of use, etc., to achieve high reliability, simple structure, The effect of large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

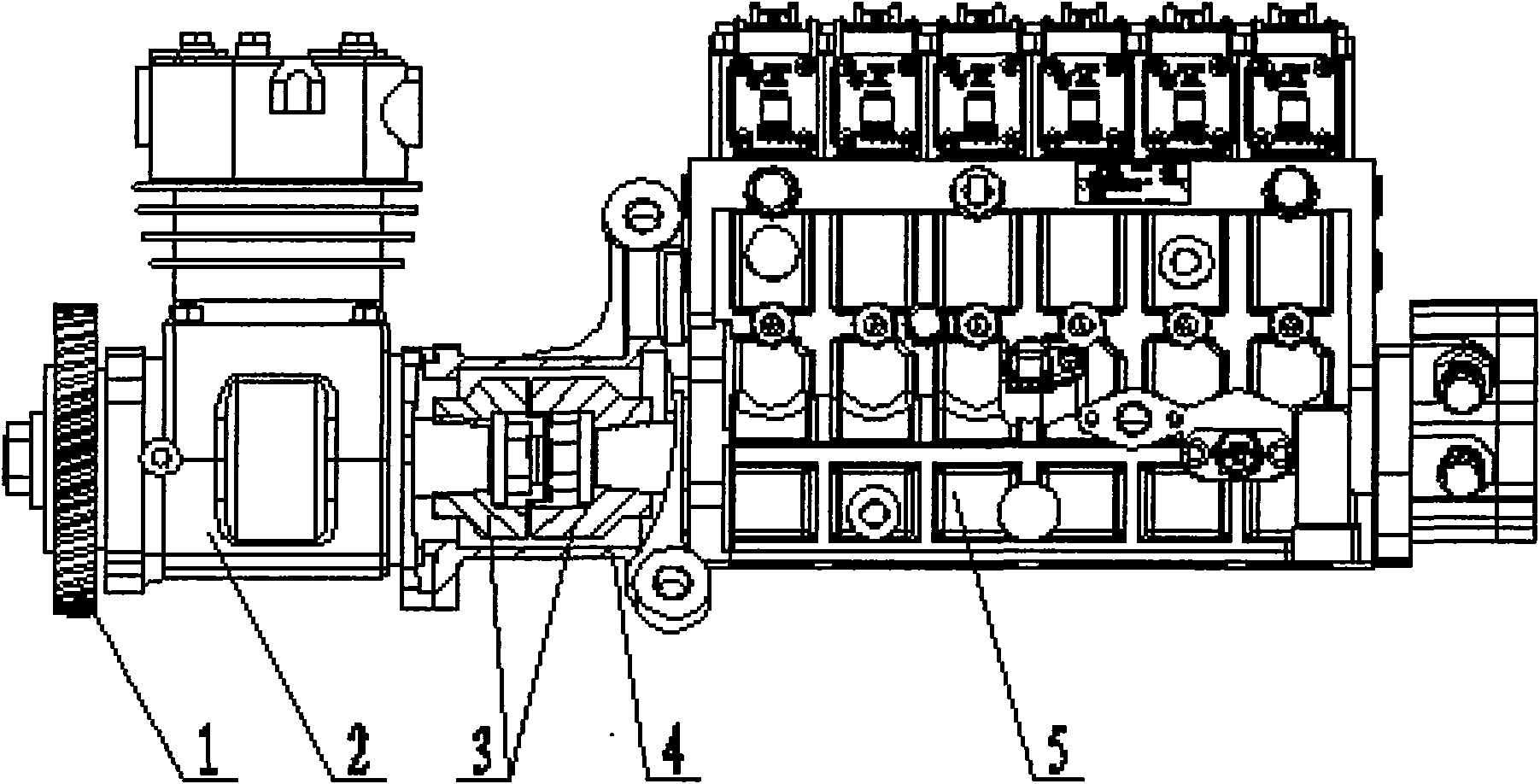

[0024] like figure 1 As shown, the engine high-torque transmission device of the present invention includes a gear assembly 1, a transmission claw assembly 3, and a transmission cover 4. The gear assembly 1 is engaged with the gear of the engine, and the gear assembly 1 is installed on the front end of the crankshaft of the air compressor 2 to control air compression. The engine 2 is running, and at the same time, the operation of the electronic fuel injection pump 5 and the timing phase angle are controlled by the transmission claw assembly 3. The transmission cover 4 connects the air compressor 2 and the electronic fuel injection pump 5 to form a sealed cavity, and the transmission claw assembly 3 is sealed in the In the cavity, lubricate and protect the transmission claw assembly 3.

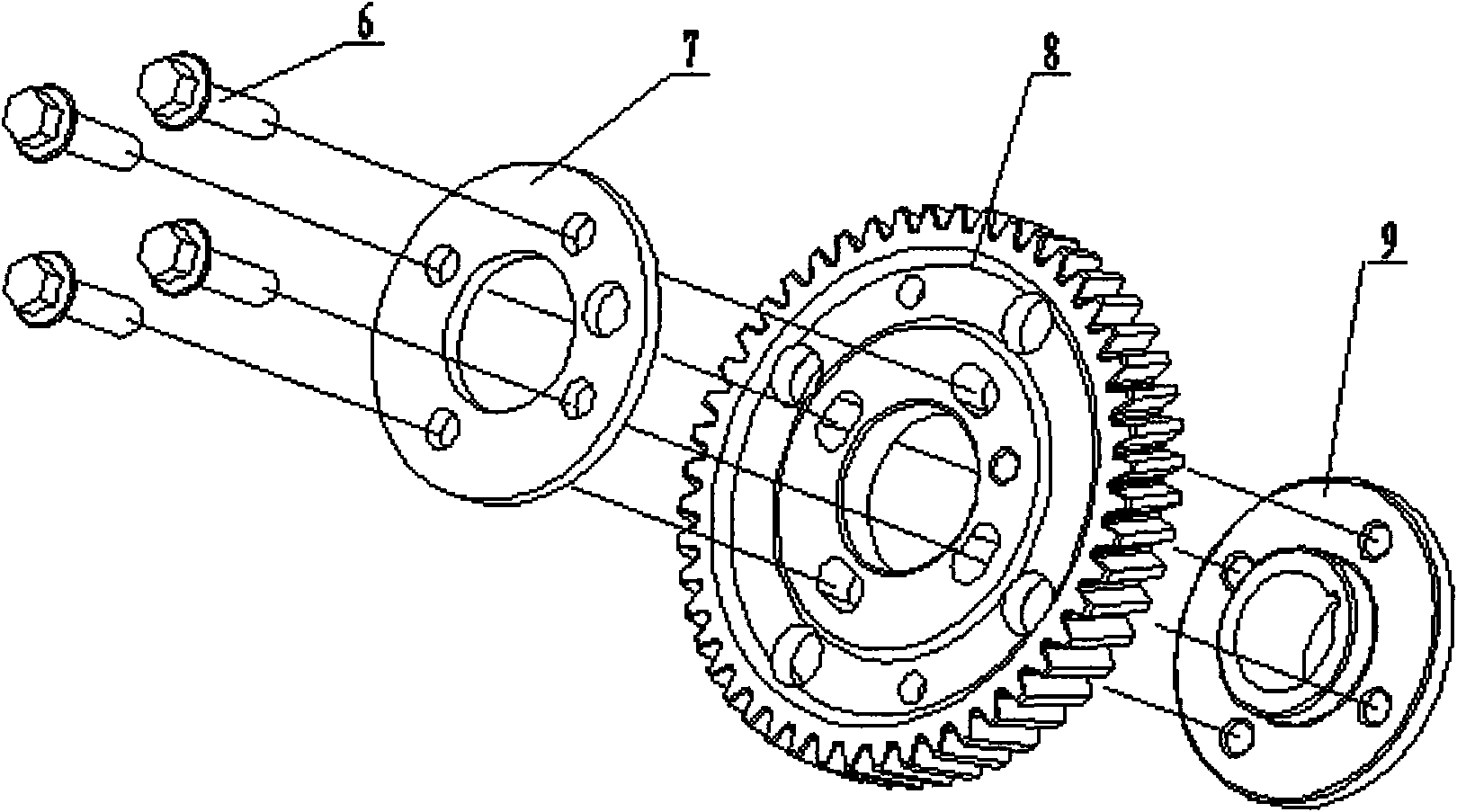

[0025] like figure 2 As shown, the gear assembly includes bolts 6, gear platen 7, air compressor gear 8, and gear seat 9. The air compressor gear 8 is installed on the gear seat 9 through fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com