Direct shear tester for field undisturbed soils

A direct shear tester and non-disturbance technology, applied in the field of direct shear tester, can solve the problems of large direct shear tester, inconvenient to carry on-site measurement, unfavorable transportation, etc., and achieve simple structure, low friction and easy to carry Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

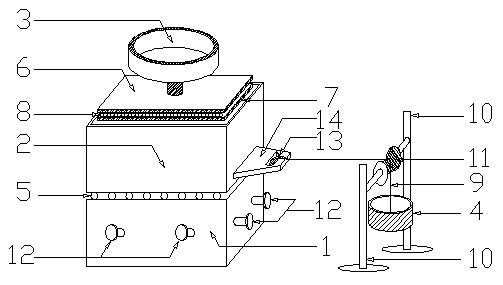

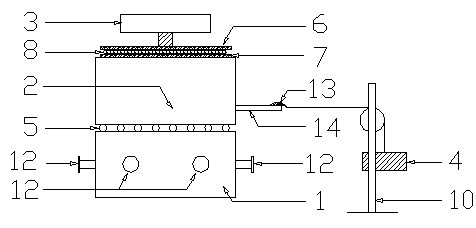

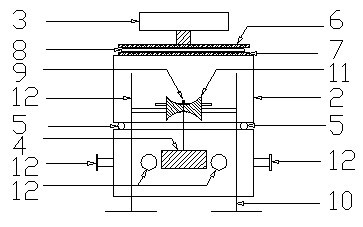

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 It is the front view of the present invention, image 3 for figure 2 right view of the Figure 4 for figure 2 As shown in the figure: the direct shear tester of the non-disturbed soil in the field of the present embodiment comprises a shearing device, a vertical loading device and a horizontal loading device, and the shearing device includes a lower shear box 1 and a sliding fit The upper shear box 2 is arranged on the lower shear box 1, and the vertical loading device includes a loading container I3 for accommodating heavy objects and is fixedly connected with the loading container I3 for undisturbed soil in the upper shear box 2. Vertically loaded force transmission assembly I, the horizontal loading device includes a loading container II4 for accommodating heavy objects and a force transmission assembly II connected to the loading container II4 for horizontally loading the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com