Three-in-one device of refrigerated compressed air dryer

A compressed air and dryer technology, applied in the field of refrigerated compressed air dryers, can solve the problems of large space occupation, low work efficiency, complex structure, etc., so as to reduce production and manufacturing costs, save installation and maintenance costs, and reduce equipment volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

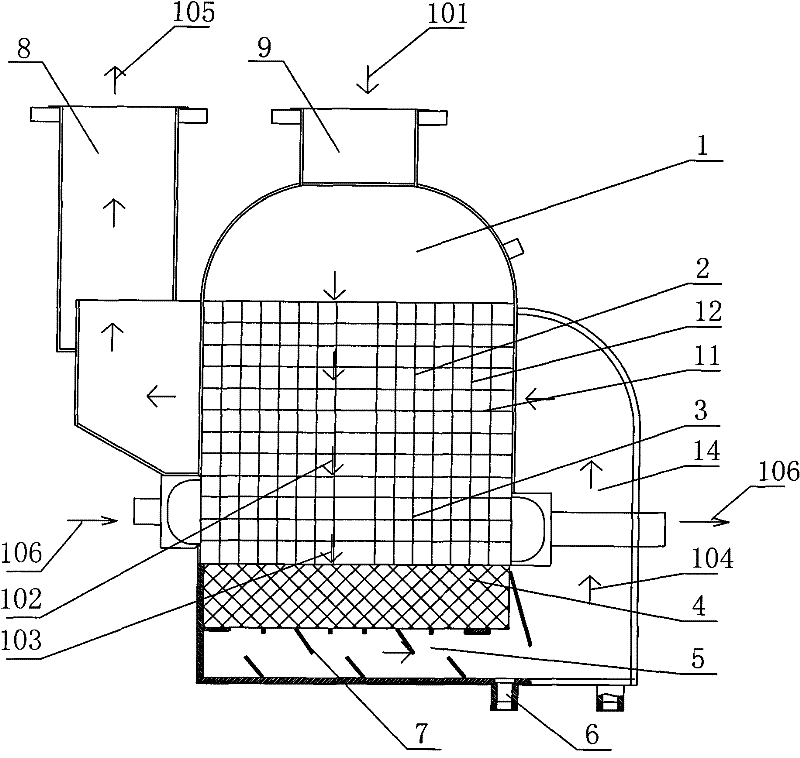

[0020] The specific implementation and working principle of the present invention will be described below in conjunction with the accompanying drawings.

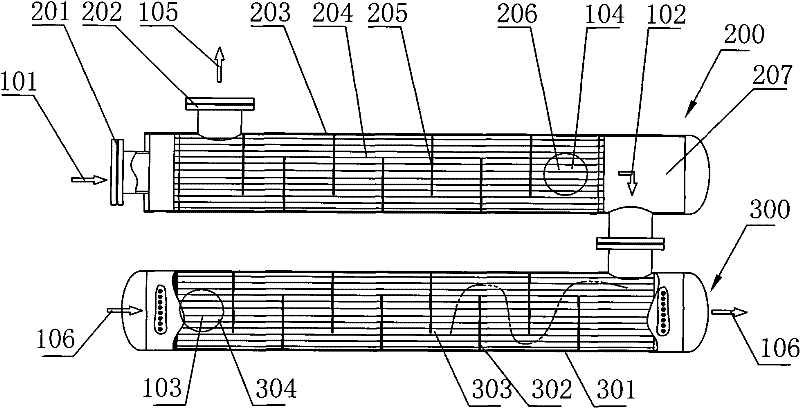

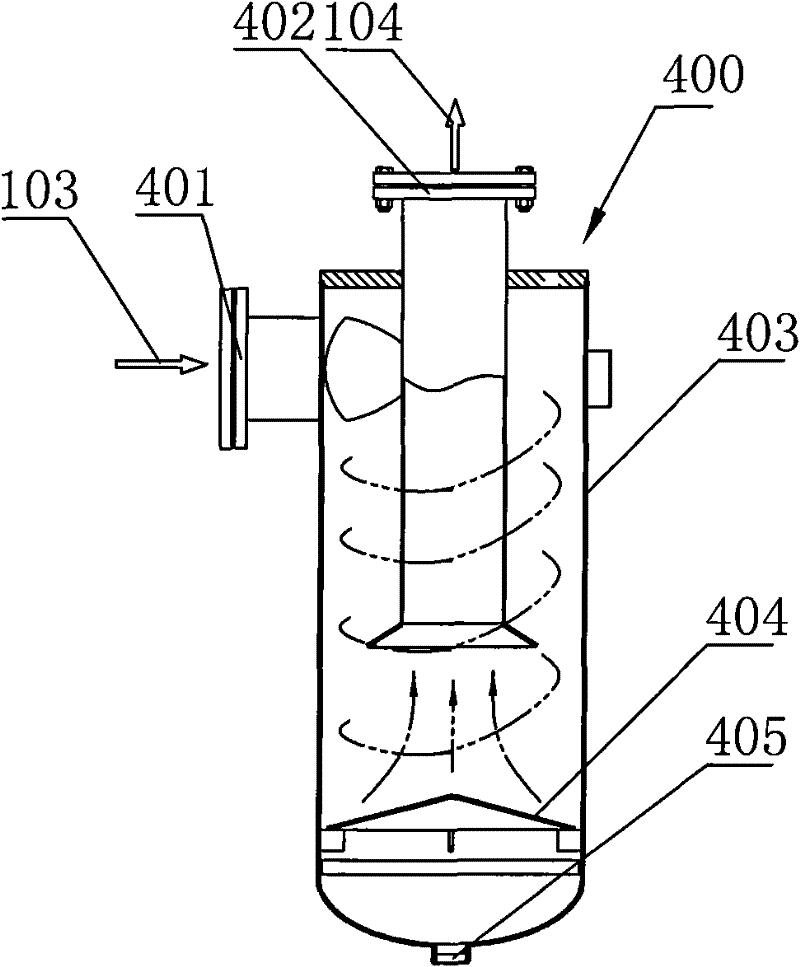

[0021] Such as image 3 , Figure 4 As shown, the refrigerated compressed air dryer of the present invention adopts an integrated structure of pre-cooling, evaporation and gas-liquid separation. The interior of the dryer shell is divided into multiple cavities, which are connected by pipelines; There are warm and humid air inlet 9 and diffusion chamber 1. Warm and humid air 101 enters from inlet 9, diffuses evenly in the diffusion chamber 1 and enters the pre-cooling chamber 2 and evaporation chamber 3 at the bottom of the diffusion chamber 1. Chamber 3 is set as Figure 5 Shown honeycomb heat exchanger 10, honeycomb heat exchanger 10 adopts such as Figure 6 The aluminum plate 15 shown in the figure is stamped into a shape similar to a trapezoidal city wall crenel that is continuously staggered, and the upper and lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com