Anti-crease bending processor for thin metal pipe

A bending process and thin metal technology, applied in the field of deep processing machinery and equipment, to achieve the effect of reducing manufacturing costs, convenient and fast operation, and meeting technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

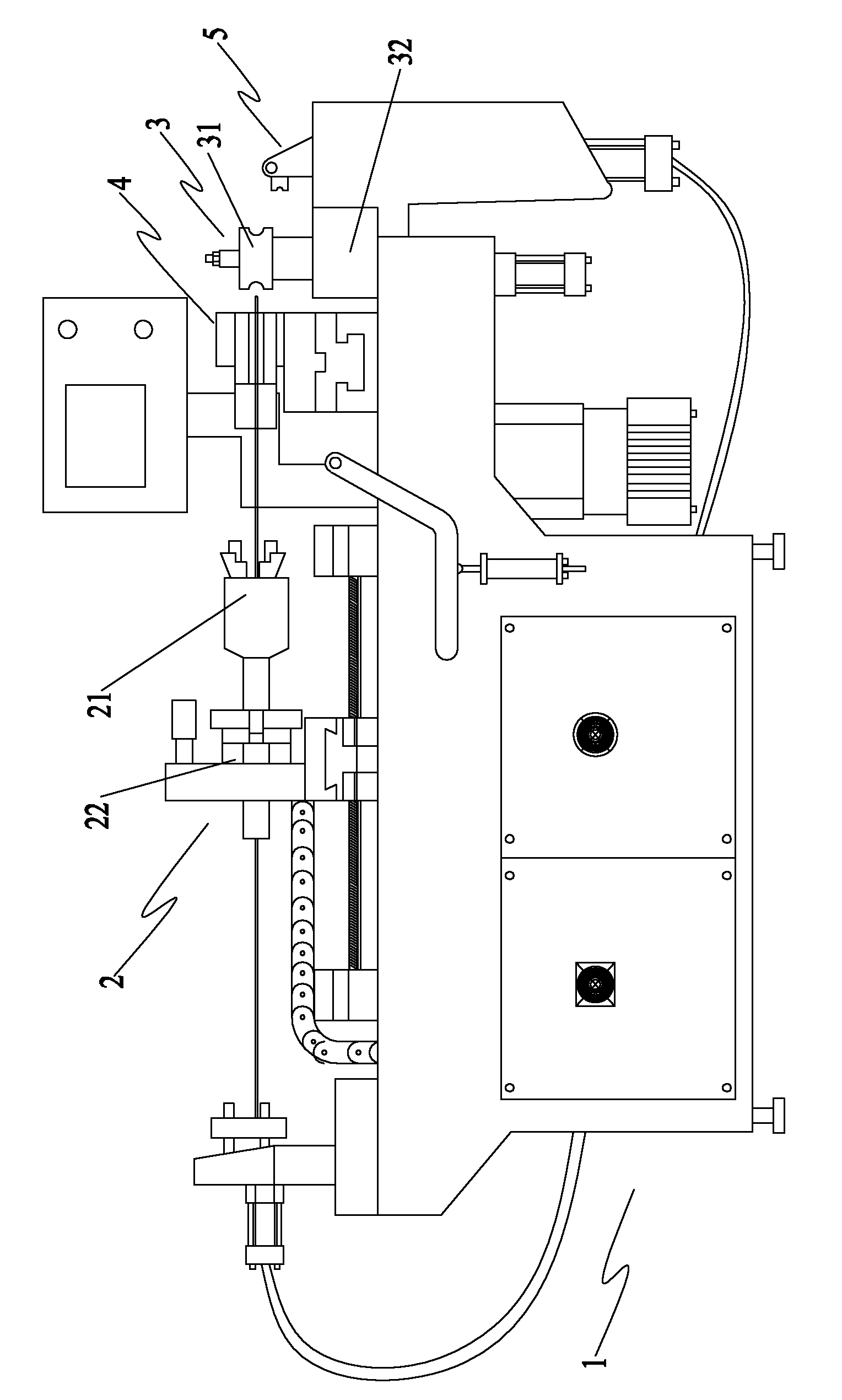

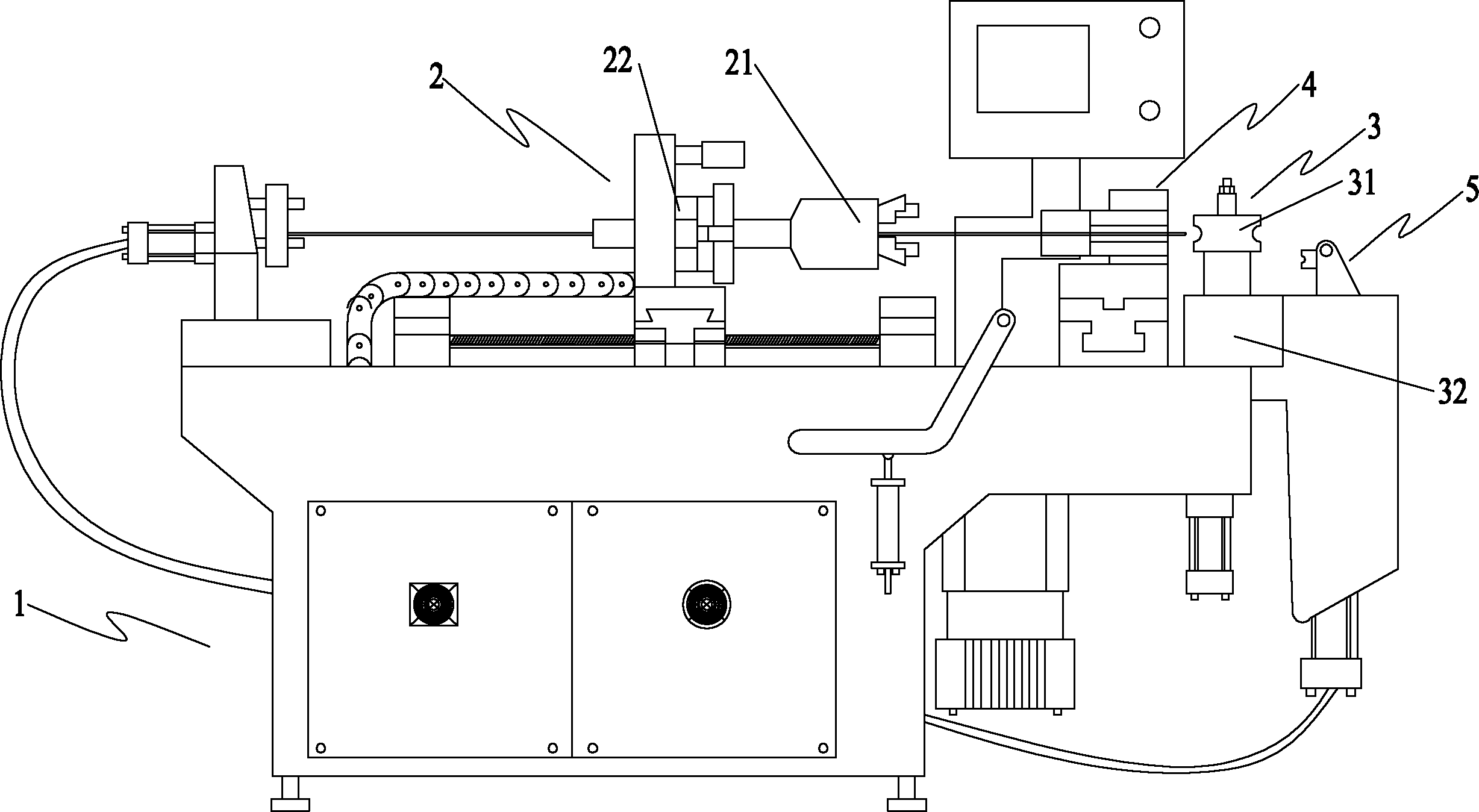

[0022] like Figures 1 to 2 As shown, the metal thin tube anti-wrinkle bending processing device of the present invention includes a base 1, and the base 1 includes a feeding part 2, a bending part 3, a guiding part 4, a clamping part 5, and an anti-wrinkle part and electrical control systems.

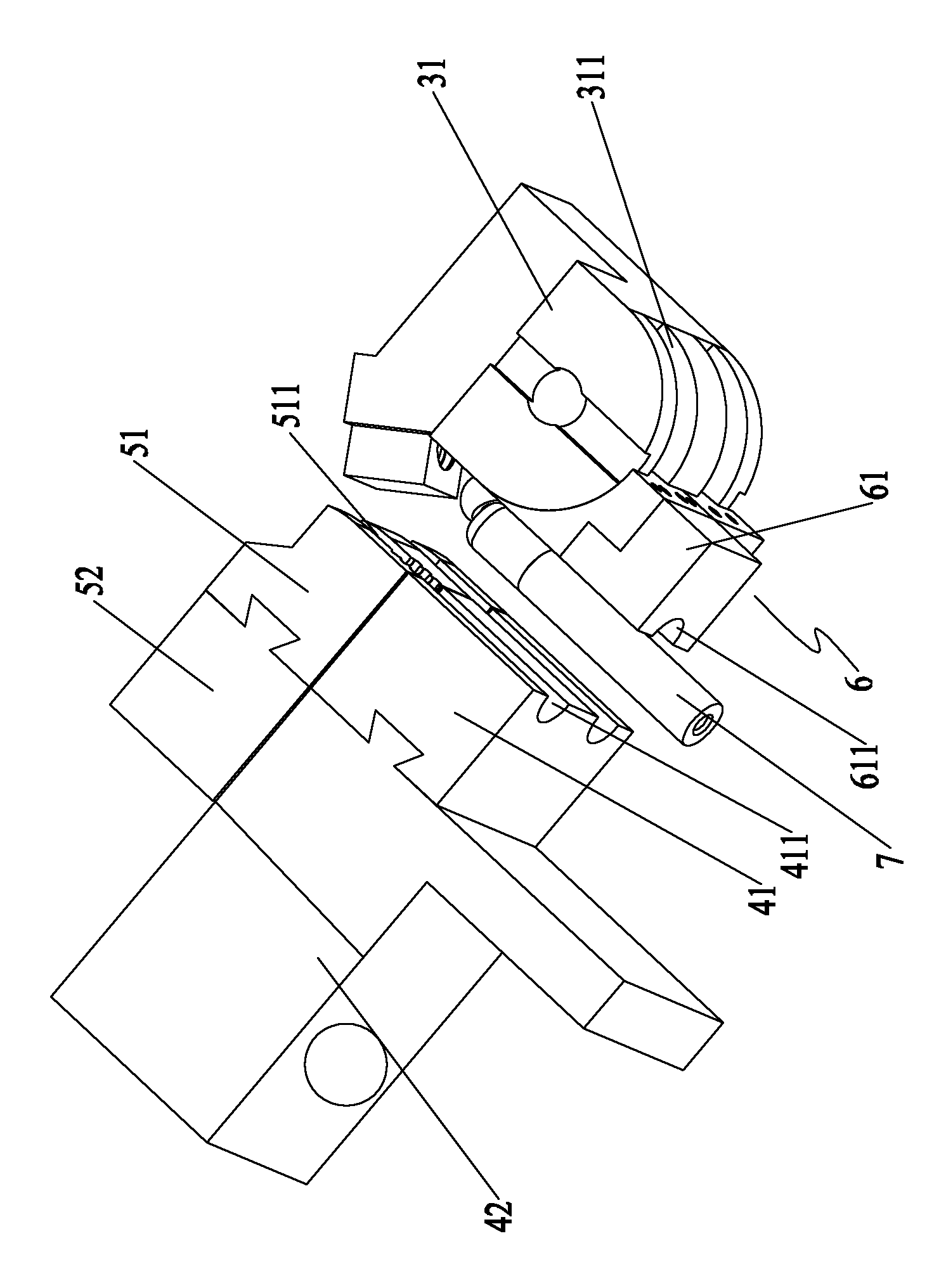

[0023] The above-mentioned bending mold part 3 includes a bending mold 31, a bending mold base 32 and a mechanical rotation system; wherein, the bending mold 31 is installed on the bending mold base 32 and cooperates with the transmission connection of the mechanical transmission system, and its side wall is circumferentially arranged There is a semicircular groove 311 , the bending die base 32 is installed on the machine base 1 , and the mechanical transmission system is installed inside the machine base 1 .

[0024] The mold guide part 4 includes a mold guide 41, a mold guide base 42 and a servo boost system; wherein, the mold guide 41 is matched with the bending mold 31 and moves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com