Trimming head for polishing pad

A polishing pad and rotary joint technology, which is applied in the direction of grinding/polishing equipment, abrasive surface adjustment devices, grinding machine parts, etc., can solve the problems of insufficient compactness and complex structure, and achieve high practicability, stable and reliable movement, Compact and beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

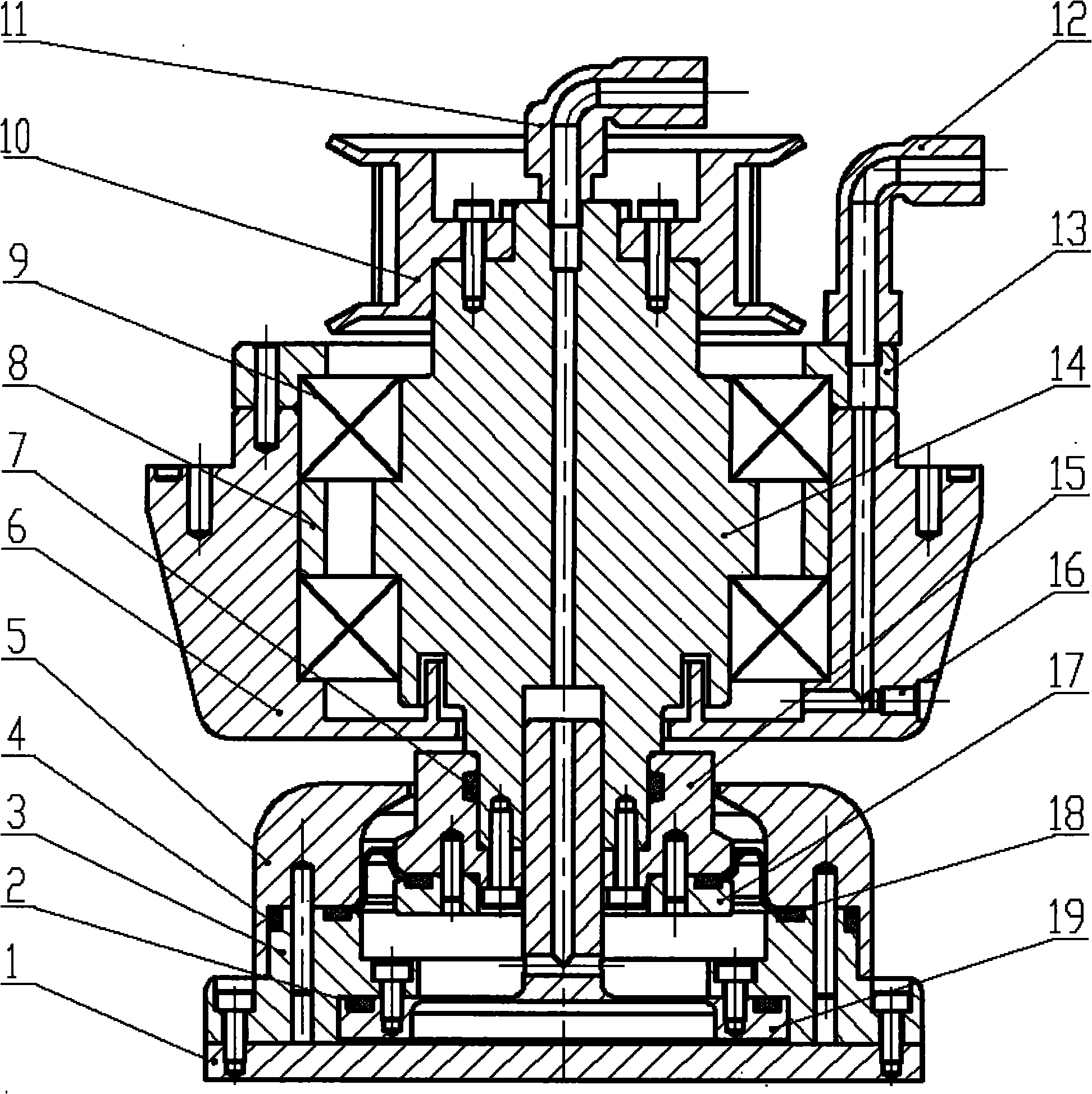

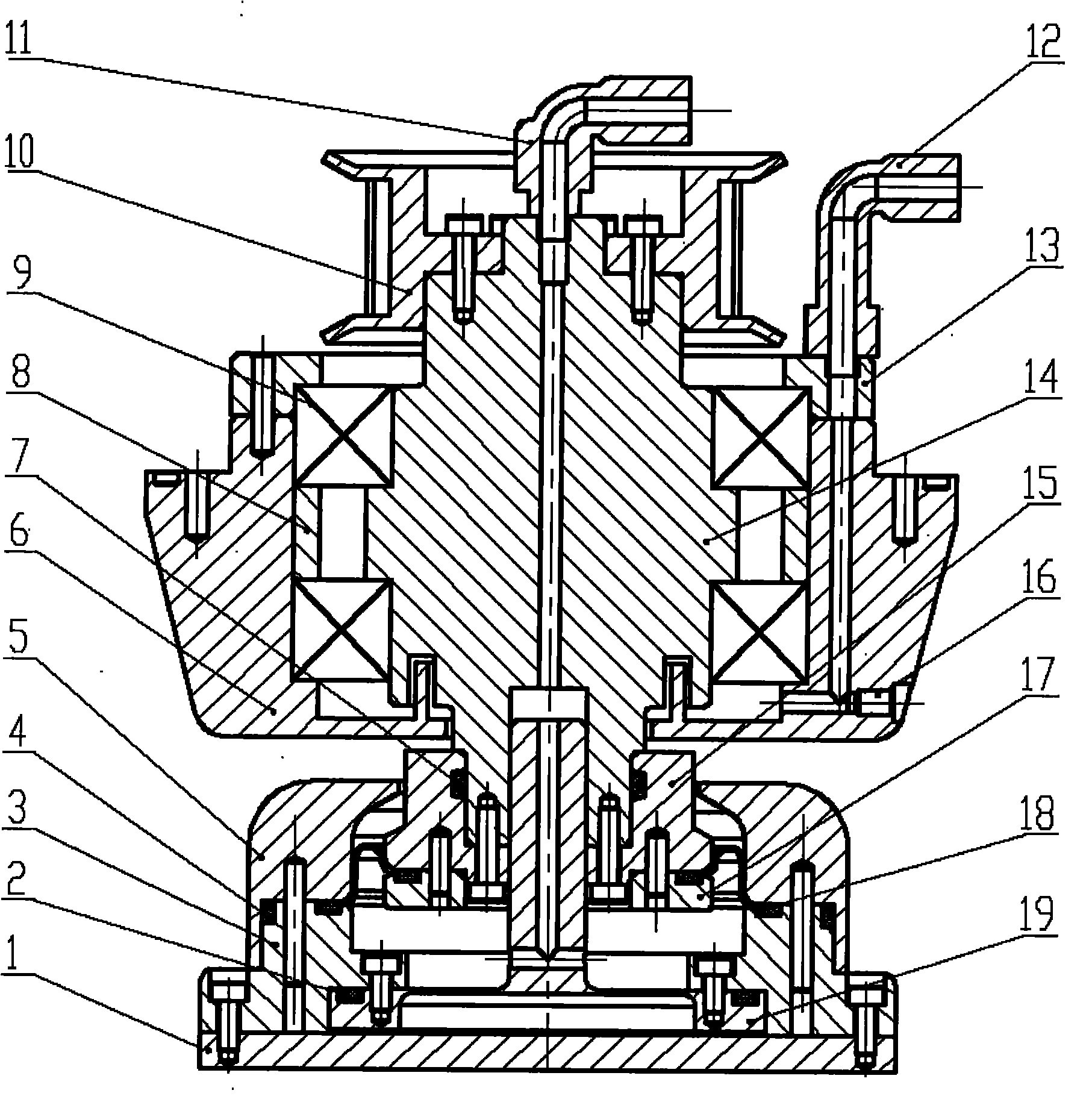

[0017] The present invention provides a polishing pad dressing head, and the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0018] like figure 1 As shown, the main shaft 14 is axially positioned by two sets of bearings 9 to avoid the axial movement of the main shaft. The bearings 9 are installed and fixed in the bearing housing 6 through the bearing end cover 13 and the sleeve 8; the bearing housing 6 and the bearing end cover 13 are arranged There are connected air holes, and the quick-change joint 12 is installed on the air hole of the bearing end cover 13; the seal between the main shaft 14 and the bearing seat 6 includes a labyrinth seal and an air seal; the top of the main shaft 14 is fixedly connected with the timing belt 10 by screws, The bottom end of the main shaft 14 is fixedly connected with the flange 15 and the pressure plate 17 by screws; the protective cover 5, the pressure plate 3, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com