Thermoplastic elastomer composite processing method of color door frame type sealing strips

A thermoplastic elastomer and composite process technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of high cost, pollution, narrow position of the mouth mold, etc., to control production costs, smooth and clean surface, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

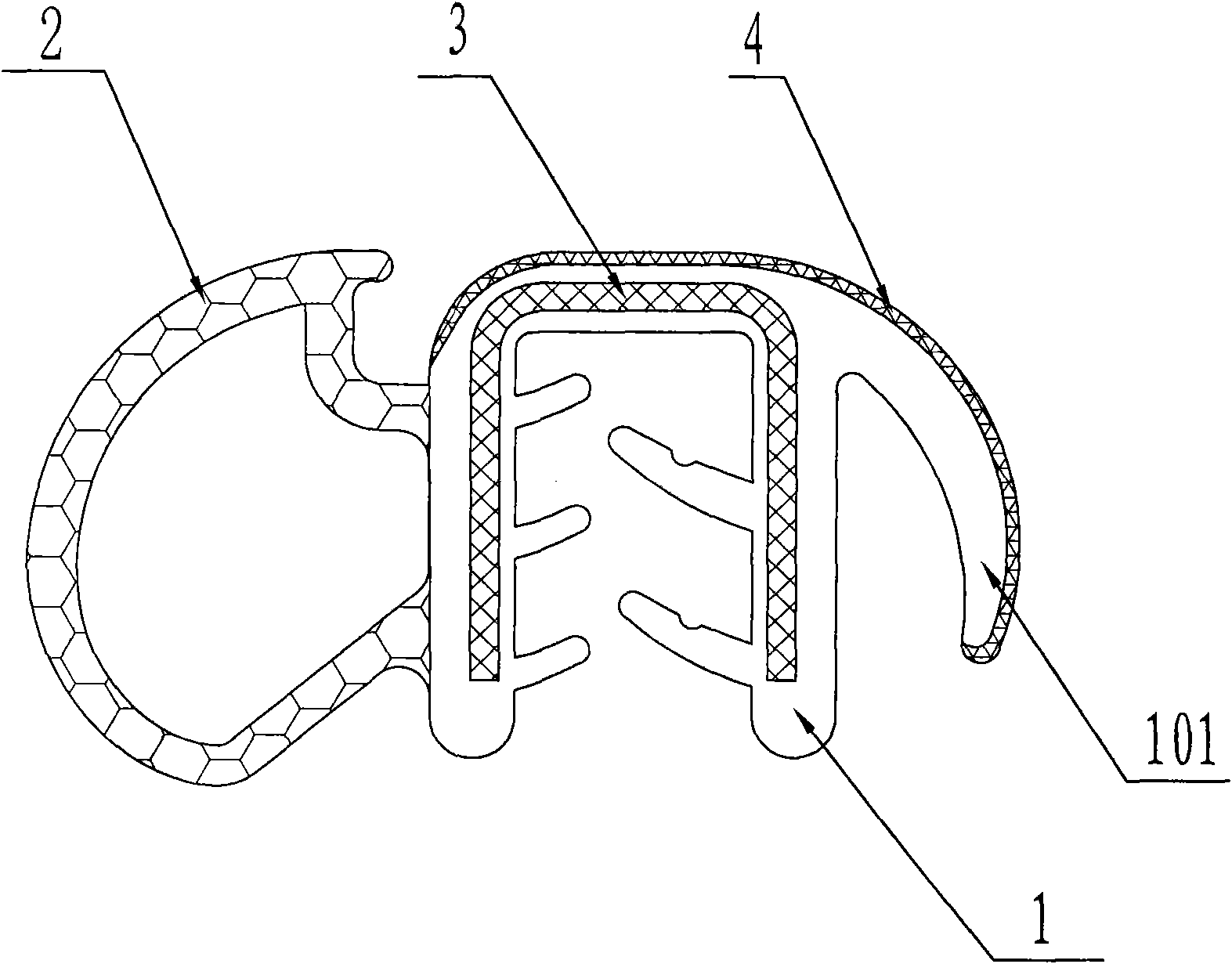

[0010] combine figure 1 As shown, the present invention is further described as follows:

[0011] The thermoplastic elastomer composite process method of the color door frame type sealing strip, the specific steps are:

[0012] (1). Feeding: feed dense rubber, foam rubber, and metal skeleton 3 into the extruder;

[0013] (2).Rubber extrusion: Preheat the die, apply silicone oil and load it into the machine head; the temperature of the compact rubber extruder is controlled at 45-55°C; the screw speed is 16.2±2rpm, and the pressure is 100-300MPa; The temperature of the foam rubber extruder is controlled at 40-50°C; the screw speed is 14±2rpm, and the pressure is 80-150MPa. Start the extruder to pull the rubber sealing strip backward; the extruded rubber sealing strip is as follows: figure 1 As shown, it is a combination of compact rubber 1, foam rubber 2, and metal skeleton 3;

[0014] (3). Microwave vulcanization: Start the microwave oven for vulcanization, and the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com