Preparation method of epoxy-modified ultra-matte acrylic acid coating

A technology of epoxy modification and acrylic acid, which is applied in the field of coatings, can solve problems such as poor salt spray resistance and light aging resistance, low testing standards, and difficult application of coatings, etc., to achieve reduced gloss and appearance leveling, excellent Good physical and mechanical properties and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

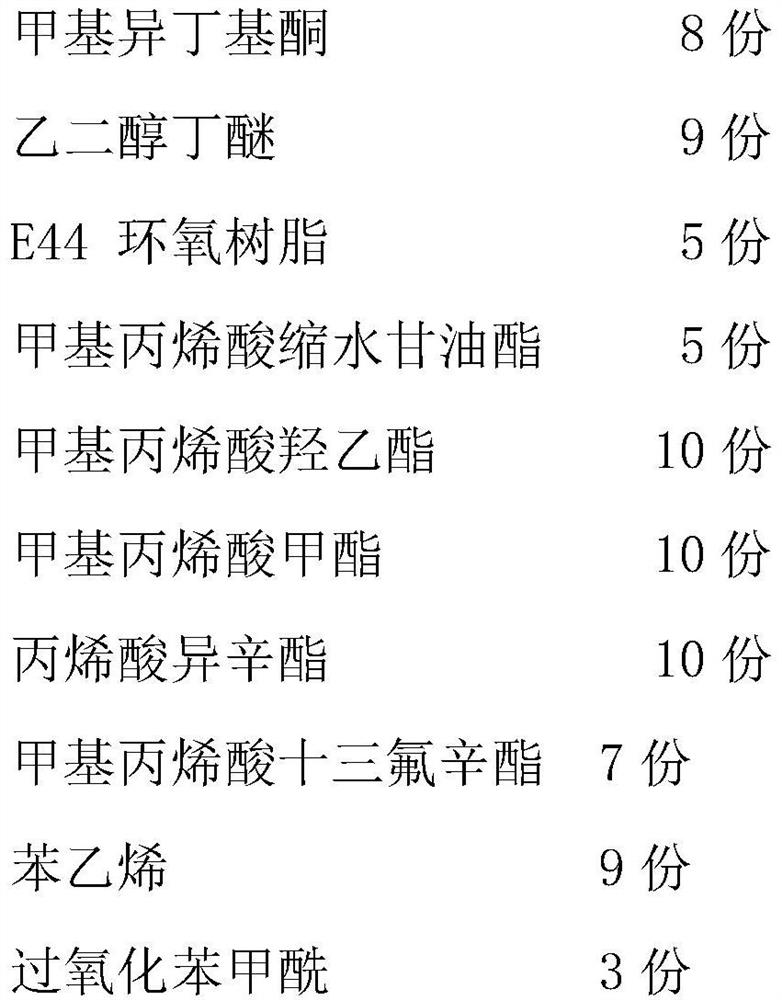

[0031] S1. Formula and preparation method of epoxy modified ultra-matte acrylic resin:

[0032]

[0033]

[0034] Glycidyl methacrylate, hydroxyethyl methacrylate, methyl methacrylate, isooctyl acrylate, trifluorooctyl methacrylate, silane coupling agent, styrene, benzene peroxide Formyl is mixed evenly and is called mixed solution A; the formula amount of benzoyl peroxide and butyl acetate is mixed evenly and is called mixed solution B. Add methyl isobutyl ketone, ethylene glycol butyl ether and E44 epoxy resin into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 115°C, and start adding the mixed solution A dropwise. After 4 hours of dripping, keep warm for half an hour, then add the mixed solution B dropwise, drop it for half an hour, then keep warm for 1 hour, cool down to 105°C, then add methyldiethanolamine dropwise according to the formula, drop it for half an hour, and heat up after the ...

Embodiment 2

[0051] S1. Formula and preparation method of epoxy modified ultra-matte acrylic resin:

[0052]

[0053] Glycidyl methacrylate, hydroxyethyl methacrylate, methyl methacrylate, isooctyl acrylate, trifluorooctyl methacrylate, silane coupling agent, styrene, benzene peroxide Formyl is mixed evenly and is called mixed solution A; the formula amount of benzoyl peroxide and butyl acetate is mixed evenly and is called mixed solution B. Add methyl isobutyl ketone, ethylene glycol butyl ether and E44 epoxy resin into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 115°C, and start adding the mixed solution A dropwise. After 4 hours of dripping, keep warm for half an hour, then add the mixed solution B dropwise, drop it for half an hour, then keep warm for 1 hour, cool down to 105°C, then add methyldiethanolamine dropwise according to the formula, drop it for half an hour, and heat up after the reaction Am...

Embodiment 3

[0070] S1. Formula and preparation method of epoxy modified ultra-matte acrylic resin:

[0071]

[0072]

[0073] Glycidyl methacrylate, hydroxyethyl methacrylate, methyl methacrylate, isooctyl acrylate, trifluorooctyl methacrylate, silane coupling agent, styrene, benzene peroxide Formyl is mixed evenly and is called mixed solution A; the formula amount of benzoyl peroxide and butyl acetate is mixed evenly and is called mixed solution B. Add methyl isobutyl ketone, ethylene glycol butyl ether and E44 epoxy resin into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 115°C, and start adding the mixed solution A dropwise. After 4 hours of dripping, keep warm for half an hour, then add the mixed solution B dropwise, drop it for half an hour, then keep warm for 1 hour, cool down to 105°C, then add diethanolamine dropwise according to the formula, drop it for half an hour, and raise the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com