Cylinder beam integrated hydraulic press

An integrated, hydraulic press technology, applied in the field of hydraulic press and cylinder beam integrated hydraulic press, can solve the problems of weakening of the upper beam rigidity and strength of the working cylinder hole, easy loosening of the threaded connection, and high quality of the whole machine, and achieves low manufacturing cost and high structure. Solid, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

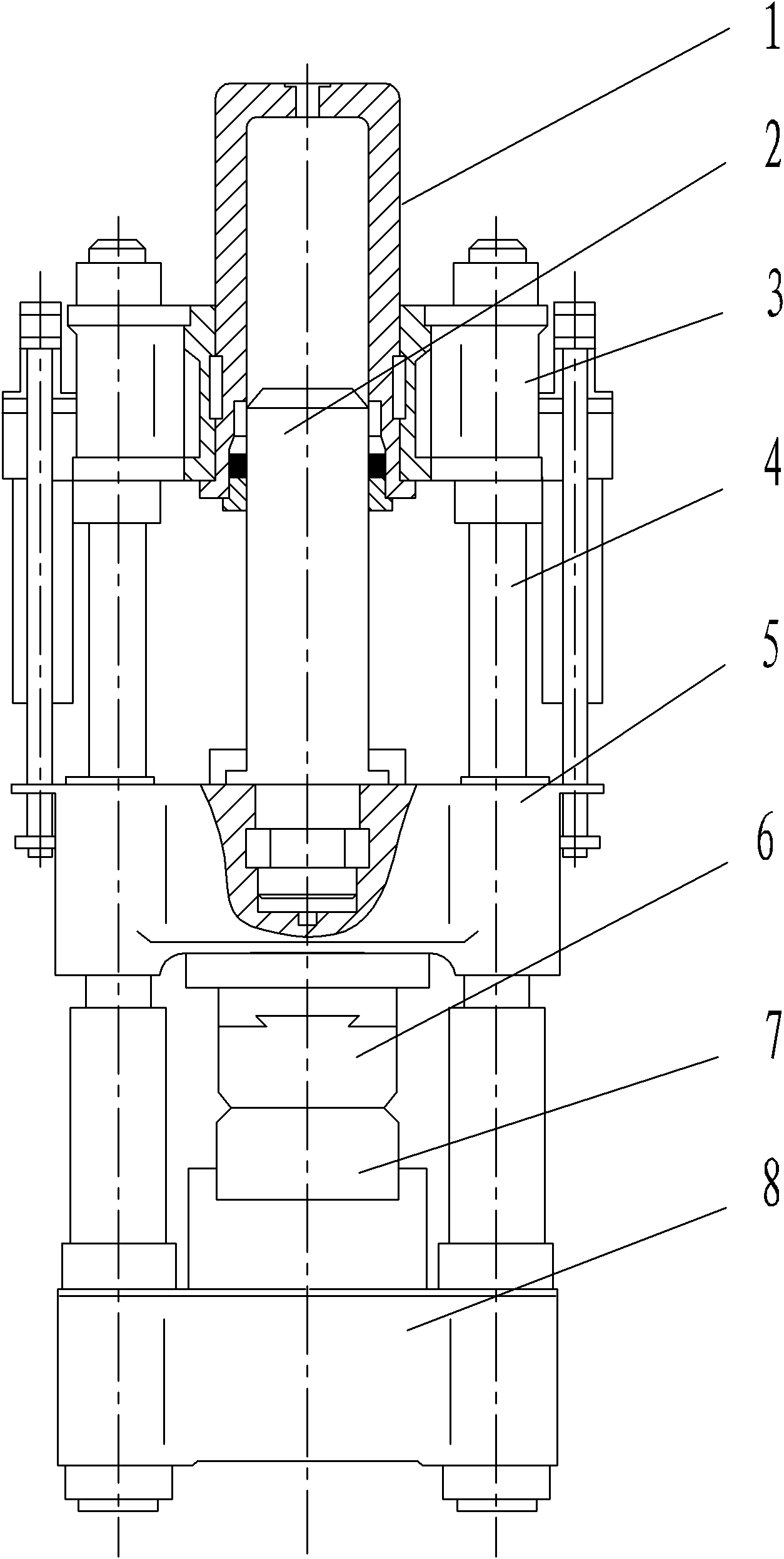

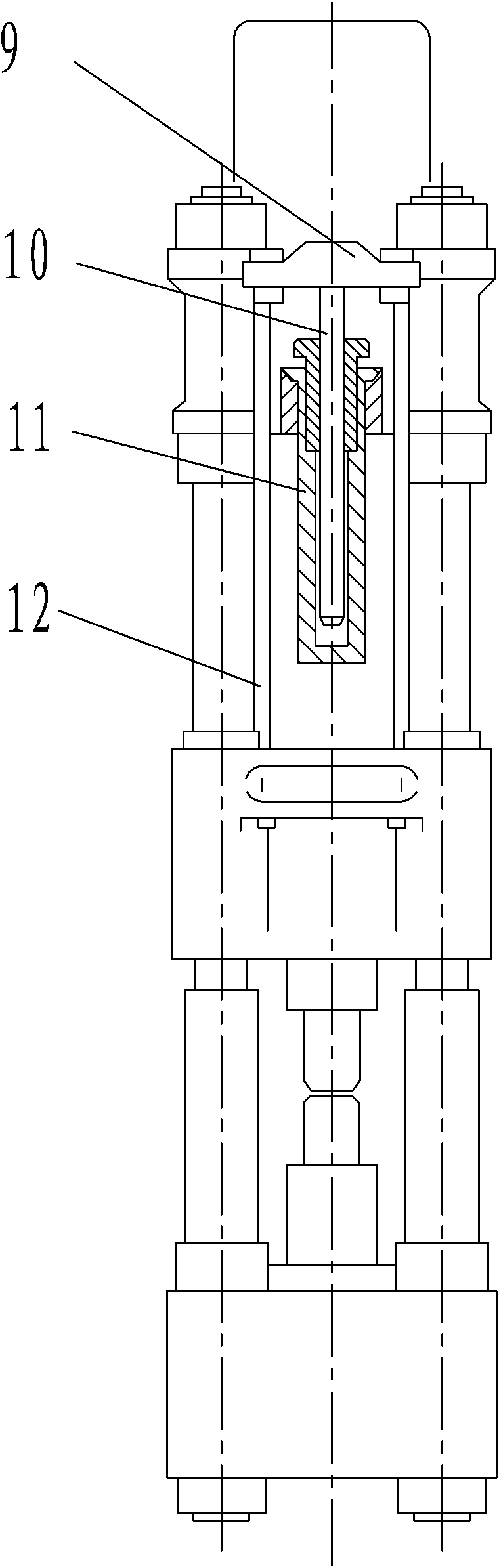

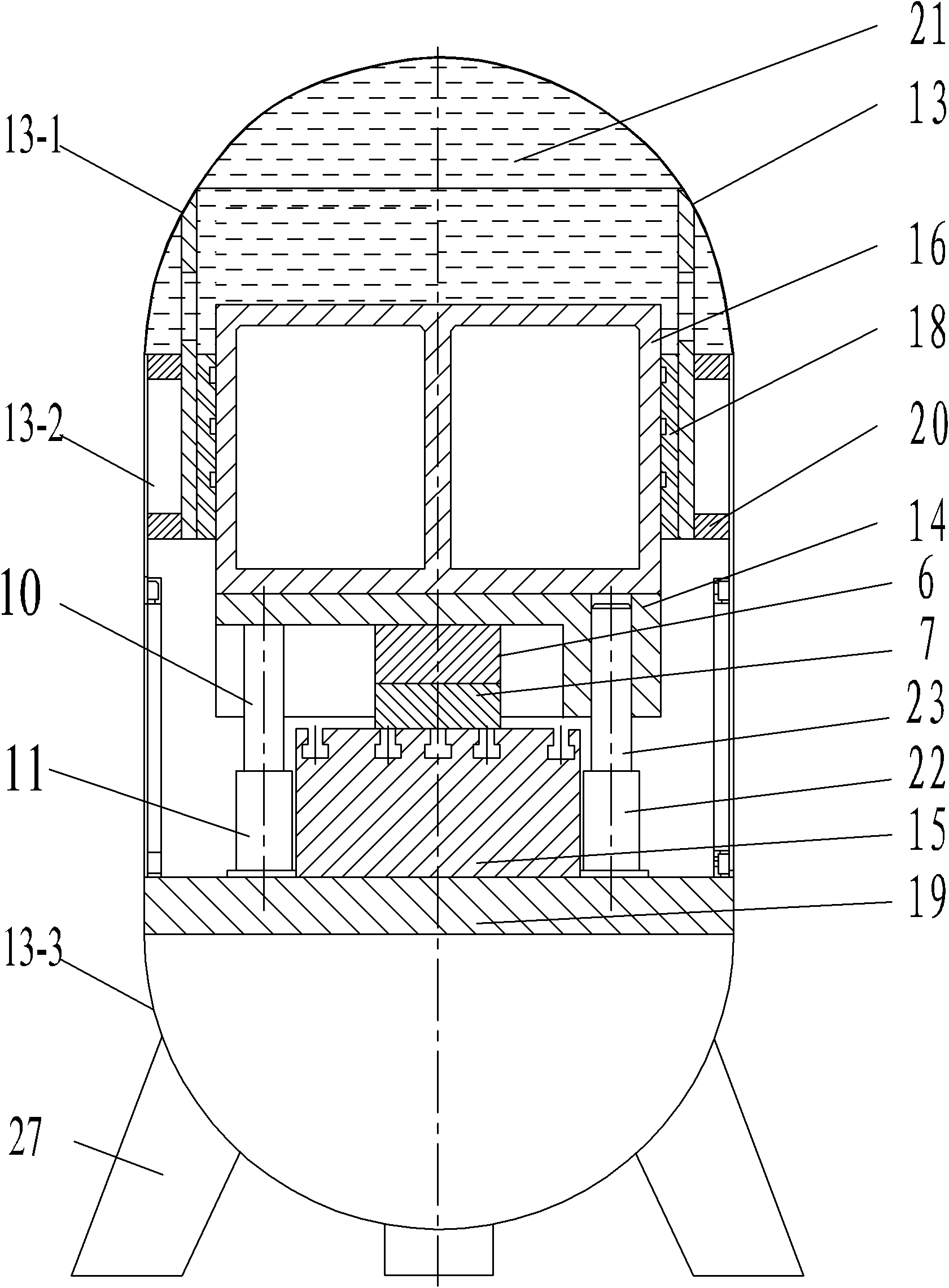

[0008] Specific implementation mode one: combine Figure 3-Figure 5 To illustrate this embodiment, the cylinder-beam integrated hydraulic press of this embodiment includes an upper die 6, a lower die 7, a workbench 15 and two return cylinders 11, and the hydraulic press also includes a housing 13, a slider 14, and a thrust plunger 16 , a sealed guide sleeve 18, a cage 20, a fixed plate 19, two guide sleeves 22, two guide posts 23 and a plurality of legs 27, the inner wall of the housing 13 is fixedly equipped with a cage 20, the cage 20 is fixed with a sealed guide sleeve 18, the thrust plunger 16 is set in the sealed guide sleeve 18, and moves up and down in the sealed guide sleeve 18, the cage 20, thrust plunger 16, belt The sealed guide sleeve 18 and the upper part of the housing 13 form a high-pressure fluid chamber 21, and the lower end surface of the thrust plunger 16 is provided with a slider 14, the slider 14 is an inverted concave slider, and the upper mold 6 is fixed...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination image 3 and Figure 4 The present embodiment will be described. The casing 13 of the present embodiment has a thickness smaller than 1 / 40 of its outer diameter. With such arrangement, the quality of the hydraulic press is lighter. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination image 3 and Figure 4 Describe this embodiment, the housing 13 of this embodiment is composed of an upper housing 13 - 1 , a middle housing 13 - 2 , and a lower housing 13 - 3 which are sequentially fixedly connected from top to bottom. Such arrangement facilitates manufacture. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com