Continuous sewage treatment device for petroleum gas well

A technology for oil and natural gas and treatment devices, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Longer service life, improved aesthetics, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

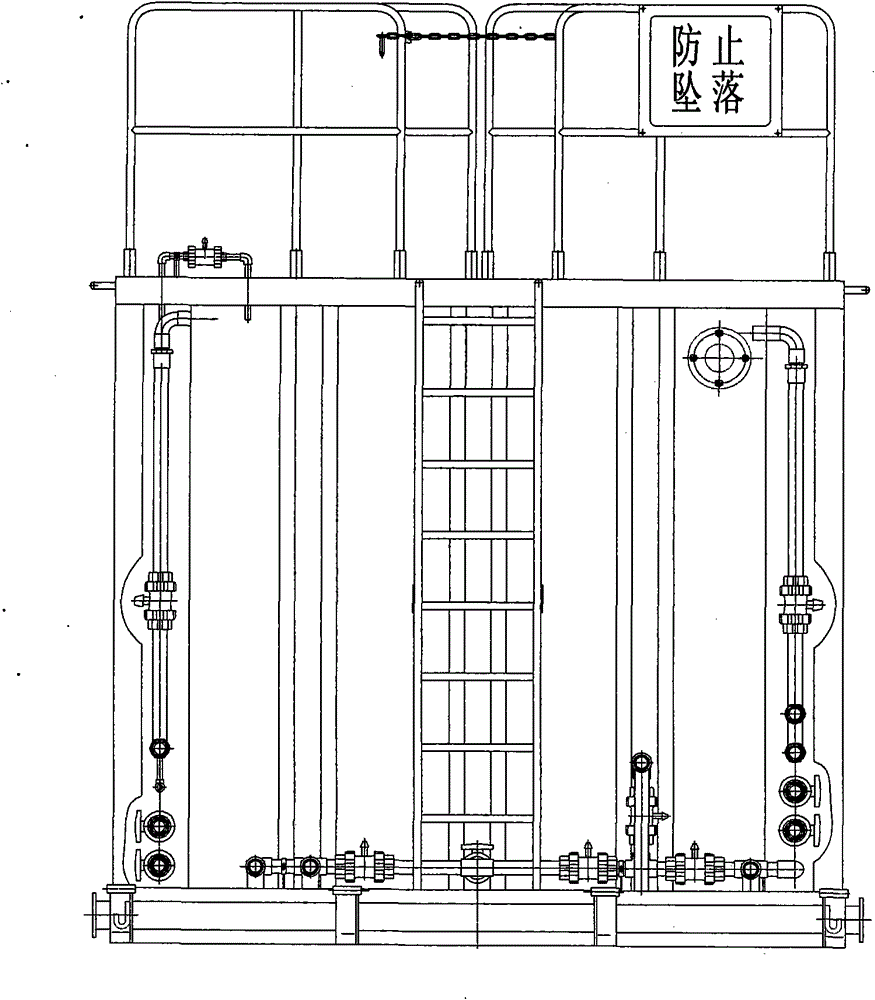

[0076] Such as Figure 1-3 As shown, the invention discloses a continuous treatment device for oil and gas drilling sewage, which includes a control room, a treatment tank and a reverse osmosis device.

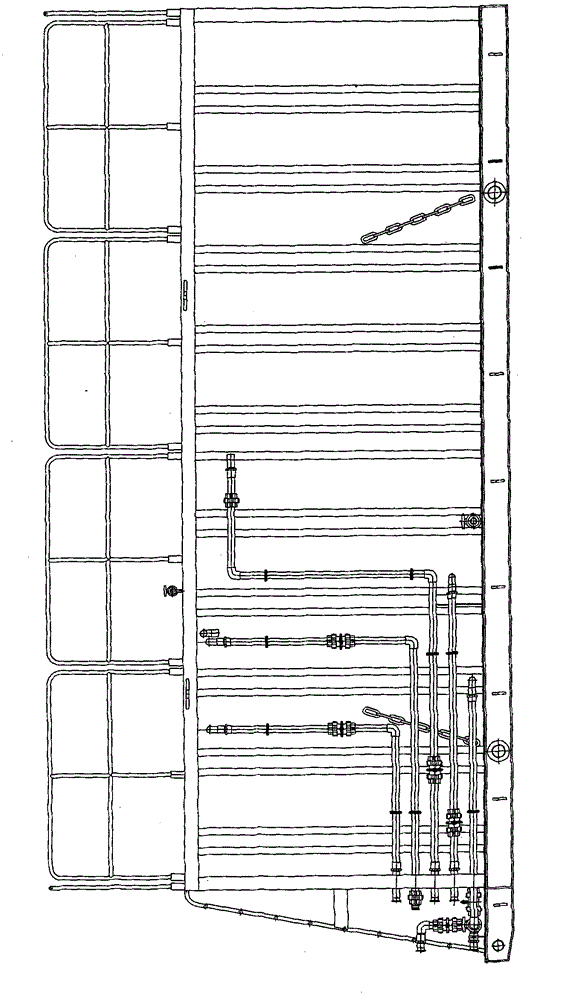

[0077] Such as Figure 4-12 As shown, a pipe rack structure is arranged between the control room, the treatment tank and the reverse osmosis device, including a pipe row support 1, and the pipe row support 1 includes two longitudinal angle steels 5, and the upper part of the two longitudinal angle steels 5 is fixedly connected at least Two horizontal positioning angle steels 4, on the vertical angle steel 5 between the two horizontal positioning angle steels 4, a plurality of evenly distributed partitions 6 are fixedly arranged, the installation direction of the partition boards 6 is the same as that of the horizontal positioning angle steels 4, and the two vertical angle steels 5 The corresponding partitions 6 are in the same position, and a groove for placing the PVC pipe 2...

Embodiment 2

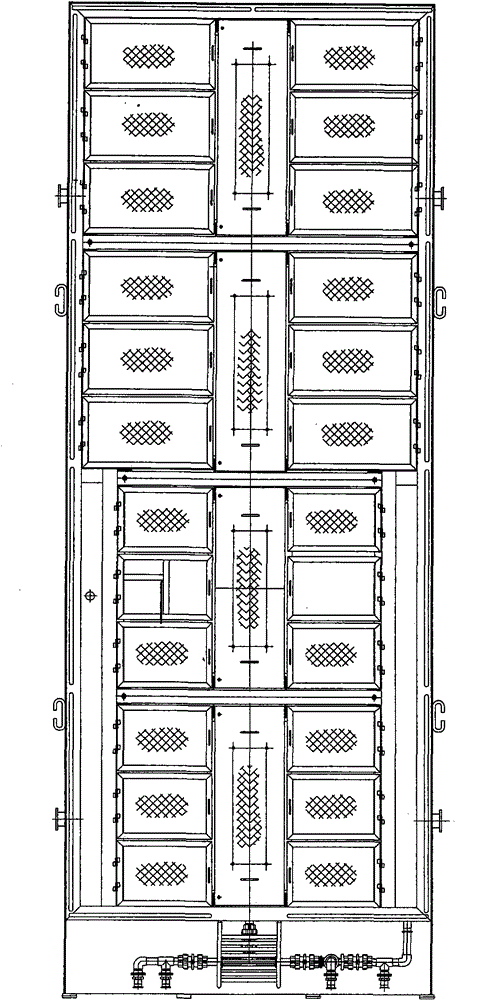

[0079] As a preferred embodiment of the present invention, such as Figure 13-15As shown, the top structure of the treatment pool includes the end pool mouth wall 11 and the side pool mouth wall 12, and the supporting square steel 4 is installed between the two side pool mouth walls 12, and the end pool mouth wall 11 and the supporting side A passageway bracket 1 is installed on the steel 4, and the embedded passageway 3 between the end pool mouth wall 11 and the supporting square steel 4 is fixedly connected with the passageway bracket 1. The vertical angle steel 2 between the support square steel 4 and the end pool mouth wall 11 is provided with a loose-leaf cover net cover 7 covering the treatment pool 10 on the plane formed by the vertical angle steel 2 and the special-shaped angle steel on the edge of the embedded passageway 3. Closed protective railings are installed around the processing pool 10 . All the other are with embodiment 1.

Embodiment 3

[0081] As a preferred embodiment of the present invention, such as Figure 16 As shown, the pool mouth plate structure includes a pool mouth plate 1, an angle steel 2 is arranged on the side of the pool mouth plate 1 of each unit, the cross section of the angle steel 2 is an isosceles triangle, and the bottom edge of the isosceles triangle is welded on the side of the pool mouth plate 1 superior. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com