Transmitting method and device of solar battery slice

A technology of solar cells and transmission devices, which is applied to circuits, electrical components, sustainable manufacturing/processing, etc., can solve problems such as machine jamming, paper breaking, jamming and paper breaking, and avoid machine jamming Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

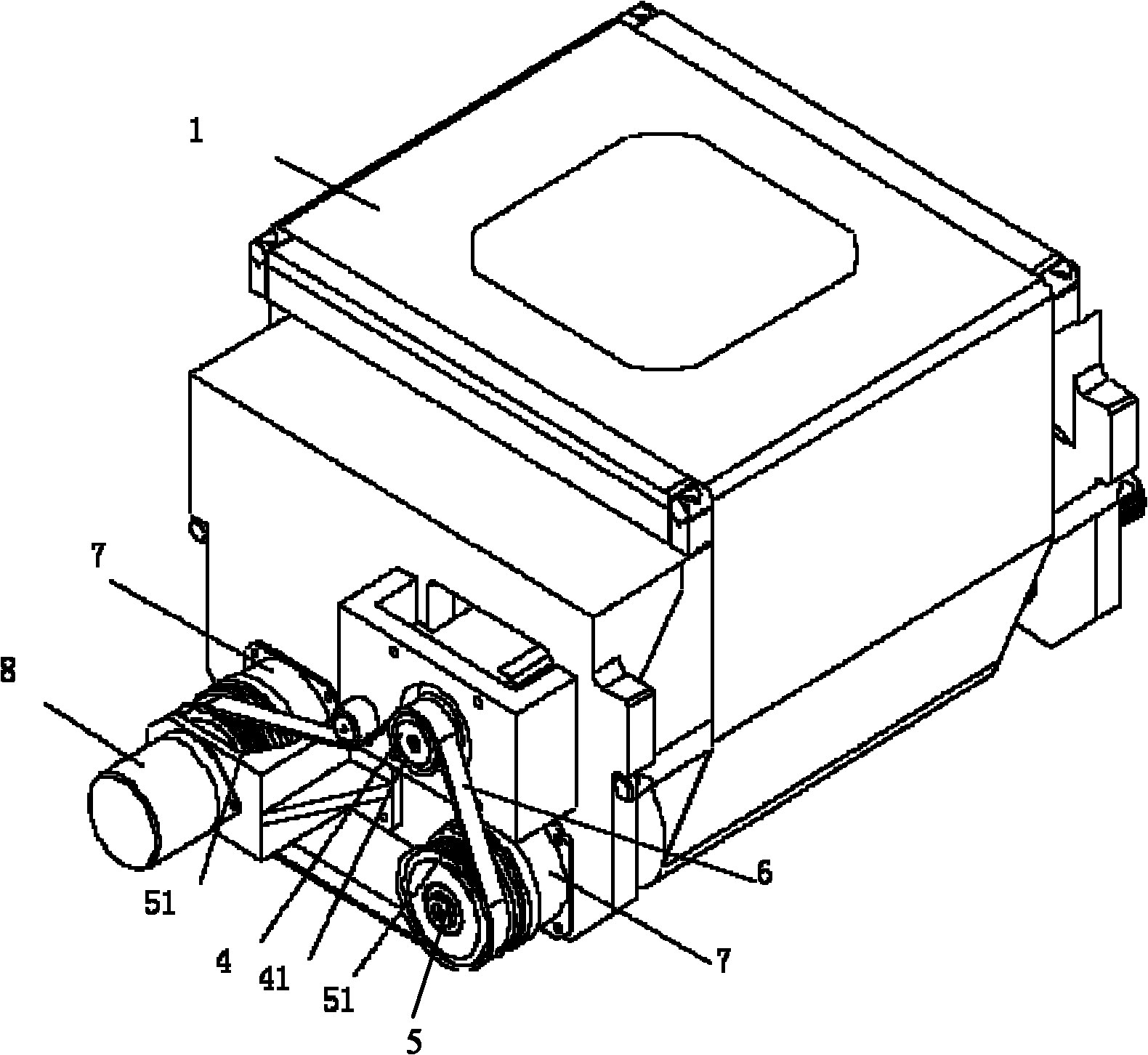

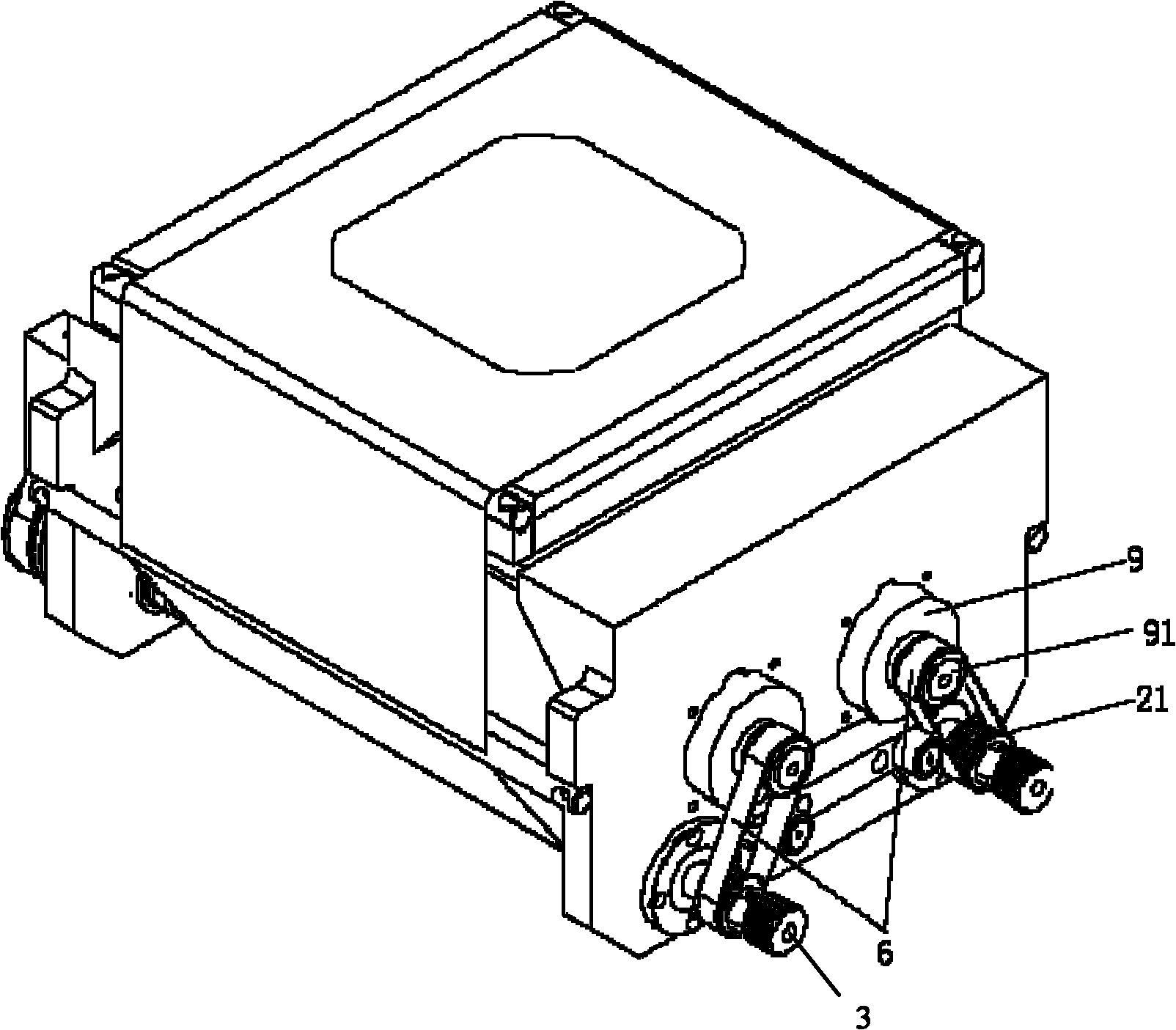

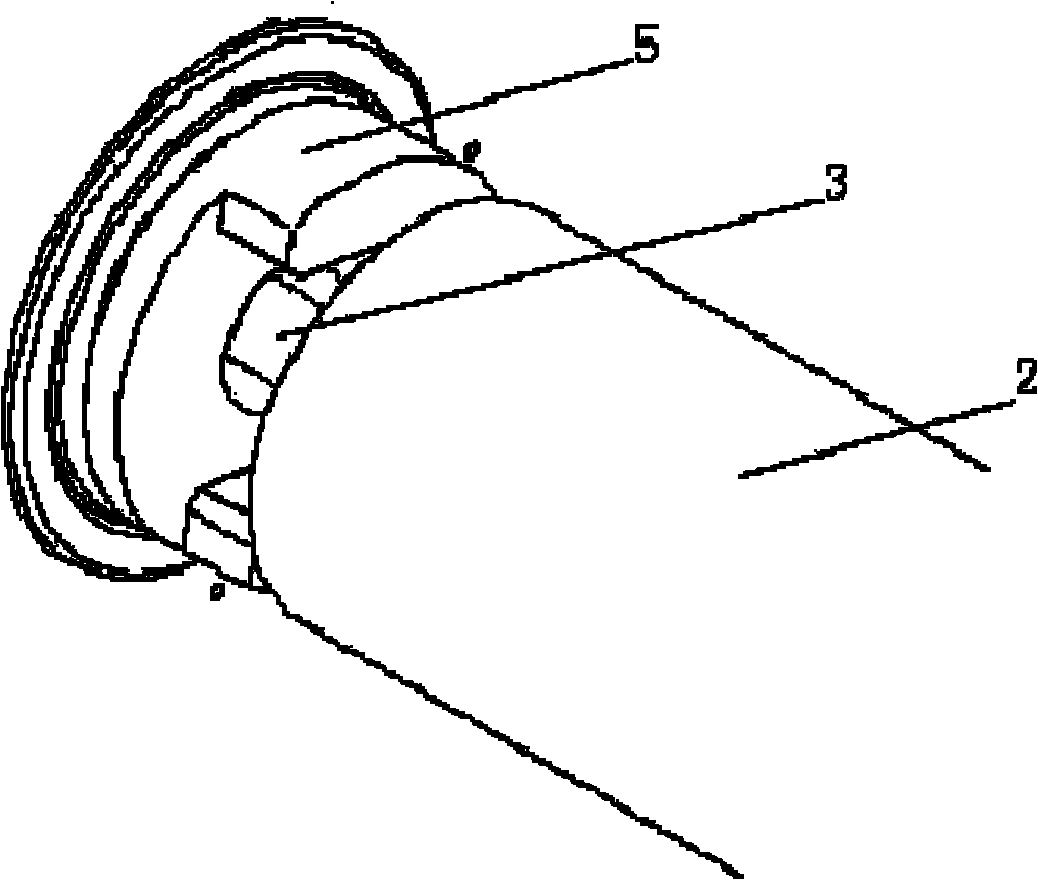

[0028] like figure 1 , 2 As shown, the transmission device of this embodiment includes a single motor transmission mechanism capable of forward and reverse rotation, a roll paper 1, two roll paper shafts 2 for installing the roll paper 1, and a roll paper shaft synchronous wheel 21. The two ends of the paper roll 1 are respectively wound on the two paper roll shafts 2; the single motor transmission mechanism includes the drive shaft 4 and its driving synchronous wheel 41 and two The driven shaft 5 and its driven synchronous wheel 51 are respectively installed on the two clutches 7 on the driven synchronous wheel 51 . The paper reel shaft synchronous wheel 21 is connected with the driven synchronous wheel 51 through the synchronous belt 6 and rotates accordingly. The distance traveled in each direction is equal. Each set of driven shafts 5 and their driven synchronous wheels 51 includes two driven shafts 5 and two driven synchronous wheels 51 respectively sleeved on the ends...

Embodiment 2

[0033] The conveying method of this embodiment adopts the conveying device as in the above-mentioned embodiment 1, including: Step 1, passing the paper through the conveying device, and conveying the solar cells to the predetermined station; Step 2, after the process of the predetermined station is completed , the solar battery sheet is sent out from the printing station through the conveying device, rewinding in the opposite direction and the same distance as in the previous step. After the rewinding action, it is determined whether the roll paper is abnormal. If the roll paper is abnormal, the rewinding action is repeated once; if the roll paper is normal, the above paper feeding action is repeated. The above-mentioned action of determining whether the roll paper is abnormal is performed once after each rewinding action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com