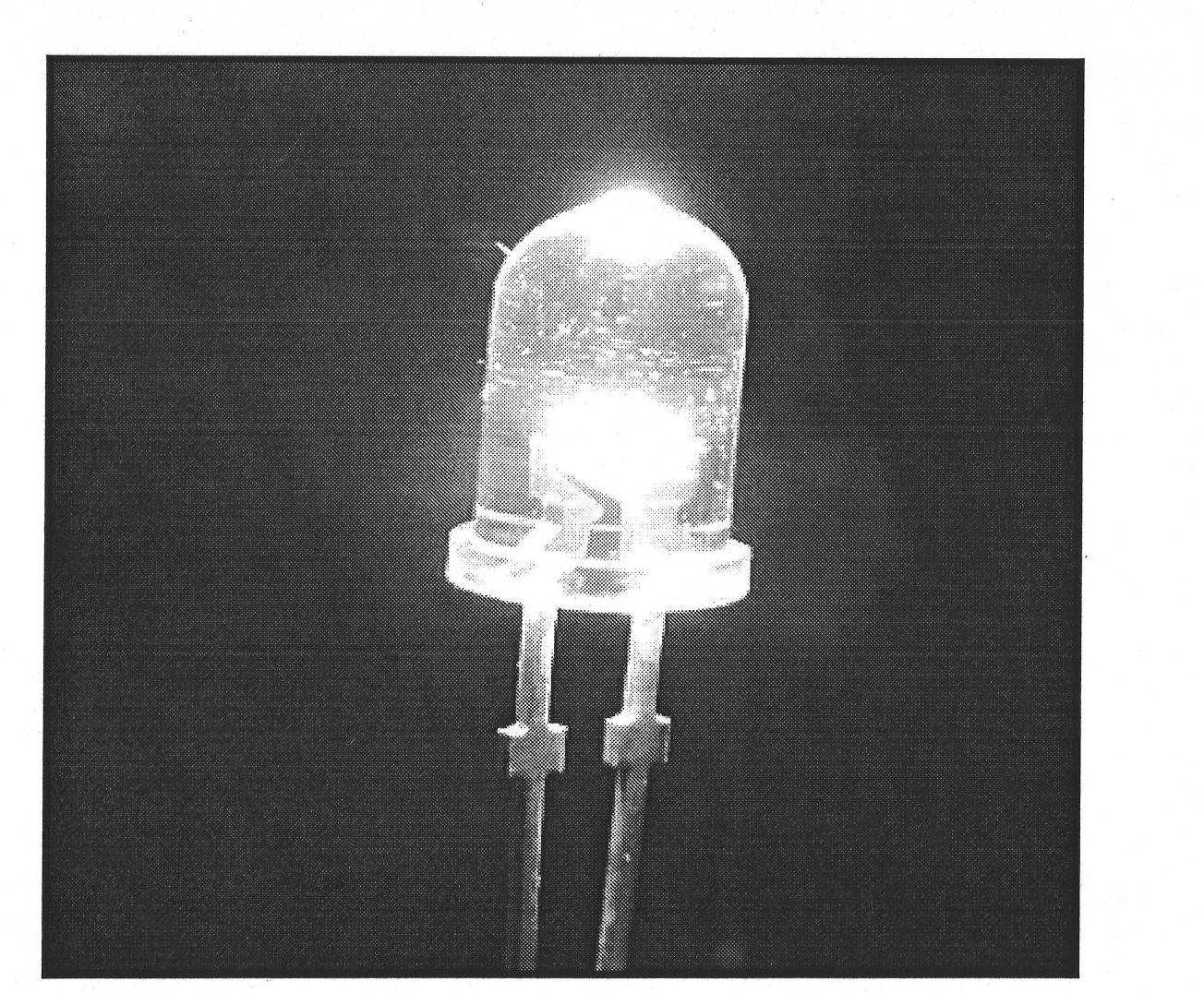

Rare earth phosphor red luminous material for converting purple light emitting diode (LED) to white light LED and preparation method thereof

A luminescent material, a technology of red luminescence, applied in luminescent materials, chemical instruments and methods, the use of gas discharge lamps, etc., can solve the problems of weak luminous intensity and complex synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] ①Material selection according to the chemical structure formula M 3-a-b-c NSi 2 o 8 :R a ·S b ·T c , when M is Ba element, N is Mg element, R is Mn element, S is Eu element, and T is Tb element, take the following high-purity materials by weight percentage:

[0020] BaCO 3 : 73.35% MgO: 5.33%

[0021] SiO 2 : 16.07% MnCl 2 4H 2 O: 2.66%

[0022] Eu 2 o 3 : 2.34% Tb 4 o 7 : 0.25%

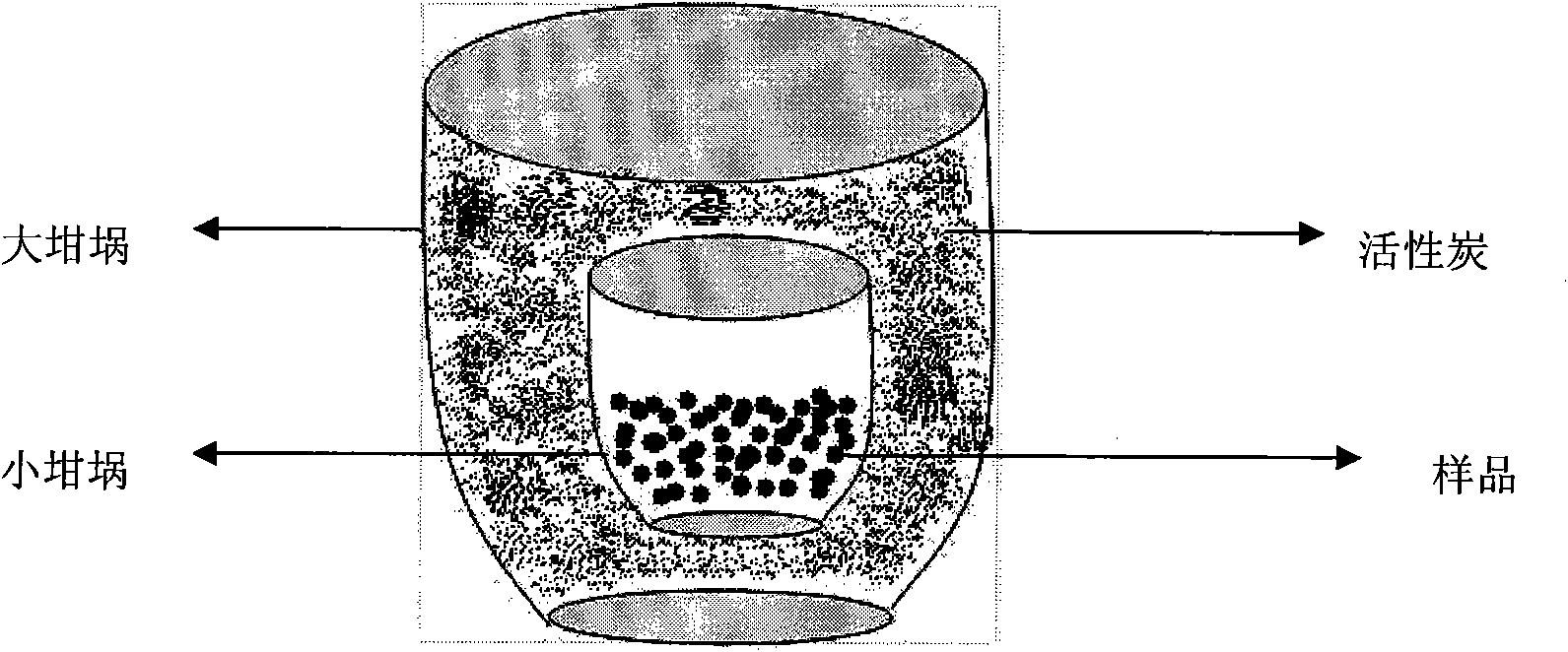

[0023] ② After grinding and mixing the above-mentioned weighed materials evenly, put them into a small alumina crucible (30ml) and add a cover, put the small crucible into a large crucible (60ml), bury the small crucible with activated carbon and add a cover, such as attached figure 1 Shown: Then put it into a high-temperature furnace for calcination at 1300°C for 2 hours.

[0024] ③ After cooling, take it out and grind it, then put it into a small alumina crucible and cover it, put the small crucible into a large crucible, bury the small crucible with activated carbon and cov...

example 2

[0026] ①Material selection according to the chemical structure formula M 3-a-b-c NSi 2 o 8 :R a ·S b ·T c , when M is Ba element, N is Mg element, R is Mn element, S is Eu element, and T is Tb element, take the following high-purity materials by weight percentage:

[0027] BaCO 3 : 73.81% MgO: 5.33%

[0028] SiO 2 : 16.07% MnCl 2 4H 2 O: 2.66%

[0029] Eu 2 o 3 : 1.88% Tb 4 o 7 : 0.25%

[0030] ② After grinding and mixing the above-mentioned weighed materials evenly, put them into a small alumina crucible (30ml) and add a cover, put the small crucible into a large crucible (60ml), bury the small crucible with activated carbon and add a cover, such as attached figure 1 Shown: Then put it into a high-temperature furnace for calcination at 1350°C for 1.5 hours.

[0031] ③ After cooling, take it out and grind it, then put it into a small alumina crucible and cover it, put the small crucible into a large crucible, bury the small crucible with activated carbon and c...

example 3

[0033] ①Material selection according to the chemical structure formula M 3-a-b-c NSi 2 o 8 :R a ·S b ·T c , when M is Ba element, N is Mg element, R is Mn element, S is Eu element, and T is Tb element, take the following high-purity materials by weight percentage:

[0034] BaCO 3 : 72.84% MgO: 5.33%

[0035] SiO 2 : 16.09% MnCl 2 4H 2 O: 2.67%

[0036] Eu 2 o 3 : 2.82% Tb 4 o 7 : 0.25%

[0037] ② After grinding and mixing the above-mentioned weighed materials evenly, put them into a small alumina crucible (30ml) and add a cover, put the small crucible into a large crucible (60ml), bury the small crucible with activated carbon and add a cover, such as attached Figure 1 Shown: Then put it into a high-temperature furnace for calcination at 1250°C for 2.5 hours.

[0038] ③ After cooling, take it out and grind it, then put it into a small alumina crucible and cover it, put the small crucible into a large crucible, bury the small crucible with activated carbon and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com