Movable electrode of variable capacitor, pressure sensor and blood pressure measuring equipment

A pressure sensor and moving electrode technology, used in fluid pressure measurement using capacitance change, variable capacitors, pressure sensors, etc., can solve problems affecting sensor linearity, distance error, parallelism error, etc., to improve production efficiency and assembly. Simple process and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

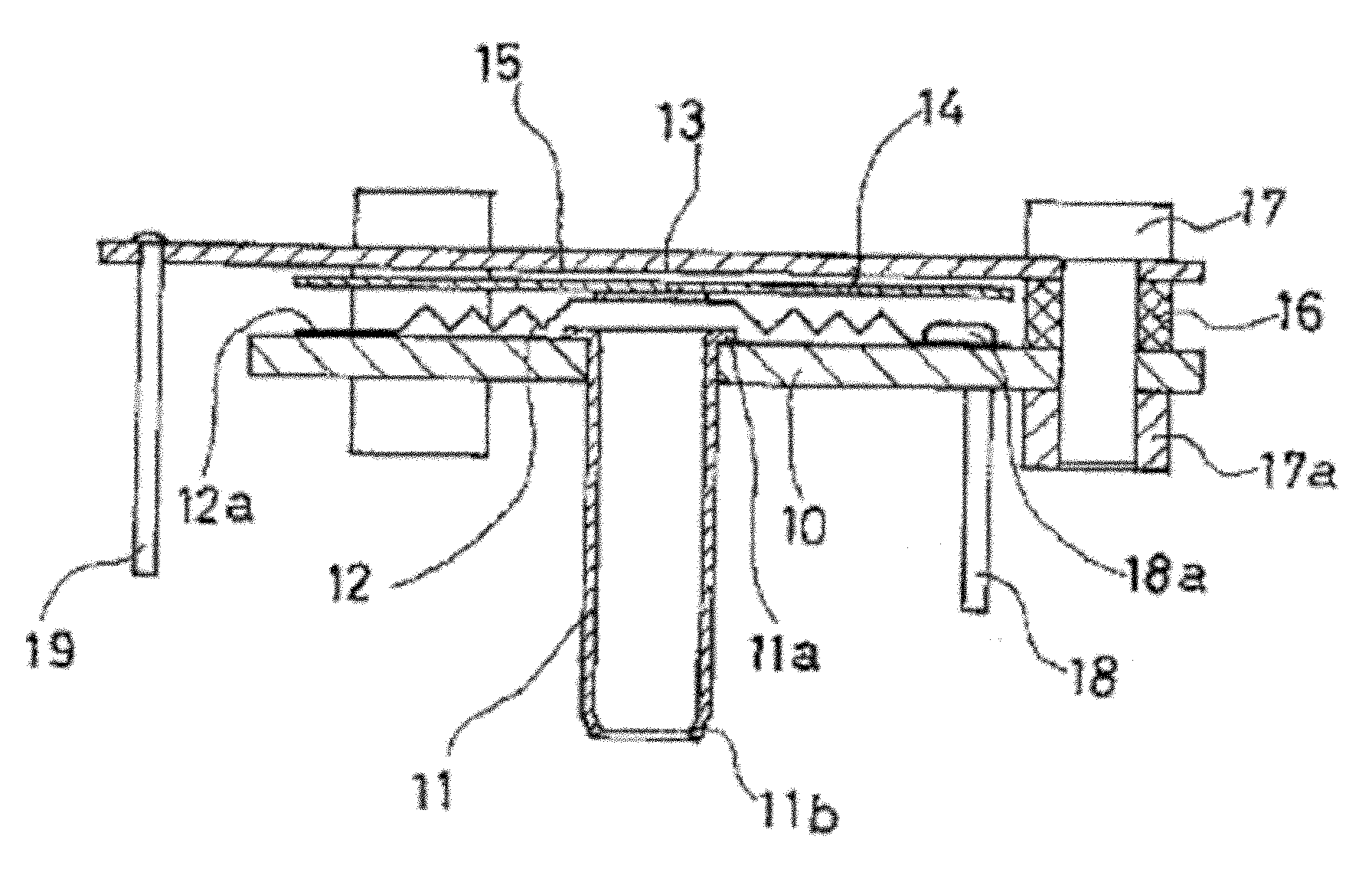

[0051] A movable electrode of a variable capacitor, such as Figure 4 and Figure 5 As shown, it includes a plate-shaped pressure sensing part 101 , an elastic deformation part 102 and a fixing part 103 provided in the radial direction of the pressure sensing part 101 . The pressure sensing part 101, the elastic deformation part 102 and the fixing part 103 are integral structures processed at one time. The thickness of the pressure sensing part 101 should ensure that when the axial force of the pressure sensing part 101 does not exceed a preset value, the pressure sensing part 101 will not be deformed or the deformation will not exceed the allowable range. The shape of the section (A-A) of the elastic deformation part 102 has a curved structure. Compared with the pressure sensing part 101, the thickness of the elastic deformation part 102 is processed into a thin structure as far as possible, so that when the pressure sensing part 101 is axially stressed, The elastic deforma...

Embodiment 2

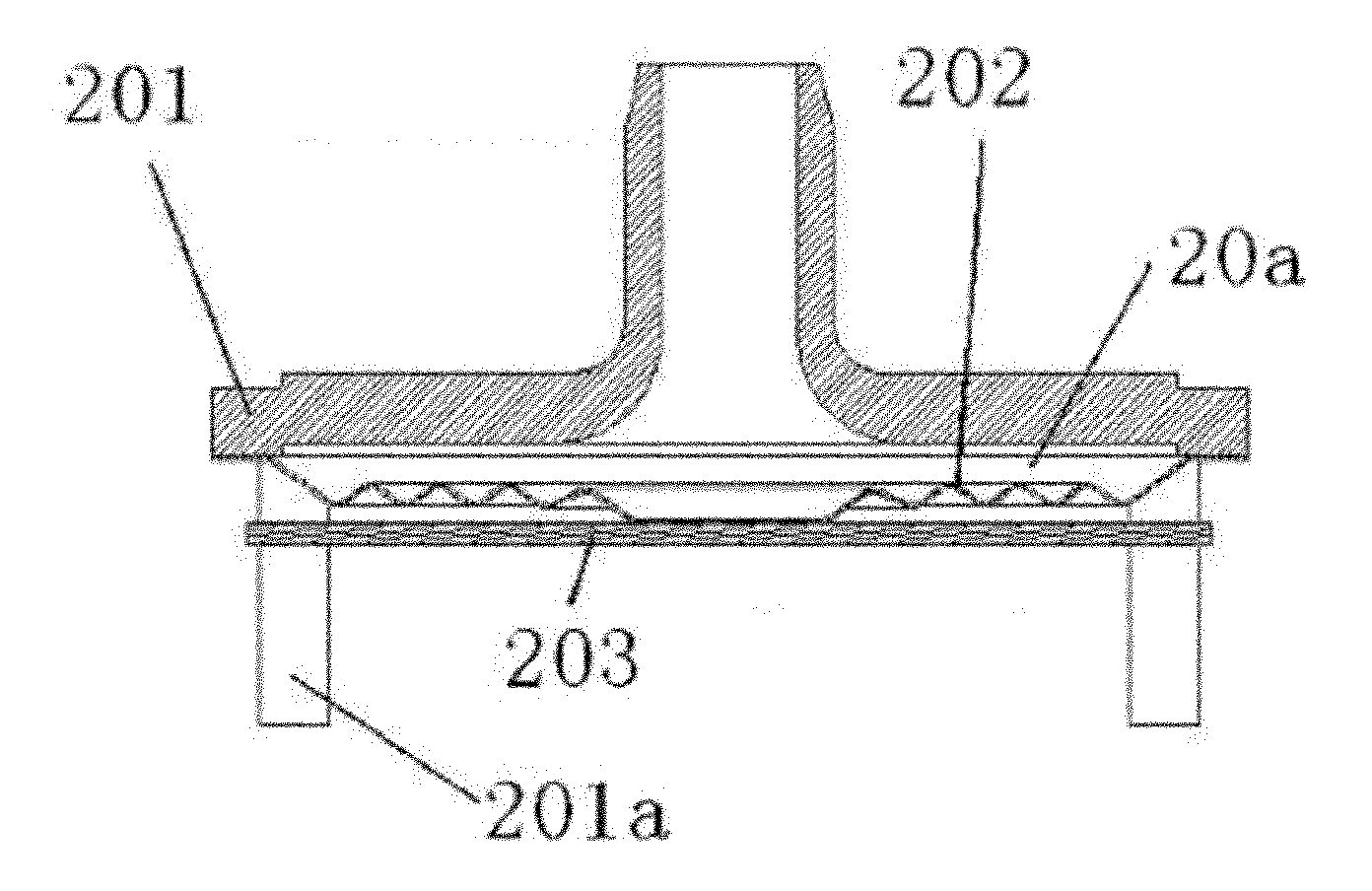

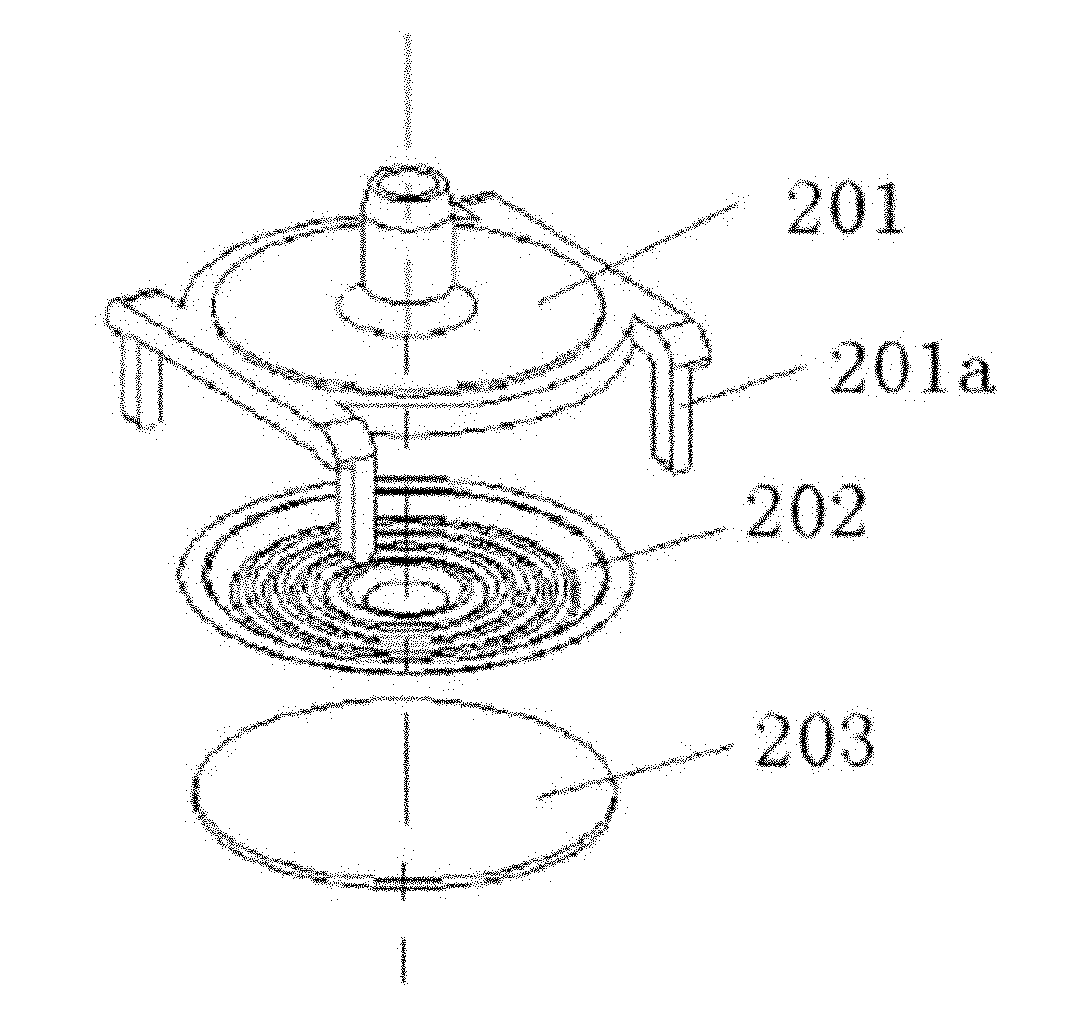

[0056] Another movable electrode of a variable capacitor, combined with Figure 6 and Figure 7 , including a pressure sensing part 201 , an elastic deformation part 202 and a fixing part 203 . The difference between this embodiment and Embodiment 1 is that the cross-sectional shape of the elastic deformation portion 202 is different: the cross-sectional shape of the elastic deformation portion 102 in Embodiment 1 is an outwardly convex curve (that is, the elastic deformation portion 102 is an outwardly convex curved surface) ), while the cross-sectional shape of the elastic deformation portion 202 in this embodiment is a concave curve (that is, the elastic deformation portion 202 is a concave curved surface). Other structures and manufacturing methods are the same as in Embodiment 1.

[0057] Those skilled in the art can understand that, in order to make the elastic deformation part elastically deform when it is stressed, the elastic deformation part can adopt the combinati...

Embodiment 3

[0059] Yet another movable electrode of a variable capacitor, combined with Figure 8 and Figure 9 , including a pressure sensing part 301 , an elastic deformation part 302 and a fixing part 303 . The difference between this embodiment and the first embodiment is that the cross-sectional shape of the elastic deformation part 302 is different: in this embodiment, the cross-sectional shape of the elastic deformation part 302 is a stepped structure. When making the elastic deformation part 302, the part to be processed is punched into a stepped structure. Other structures and manufacturing methods are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com