Integral catalyst for NOx selective catalytic reduction and preparation method thereof

A monolithic catalyst and catalyst technology, applied in the field of environmental pollution control, can solve the problems of narrow operating window, health and toxicity of alum compounds, etc., and achieve the effects of low load shedding rate, simple preparation method and high loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

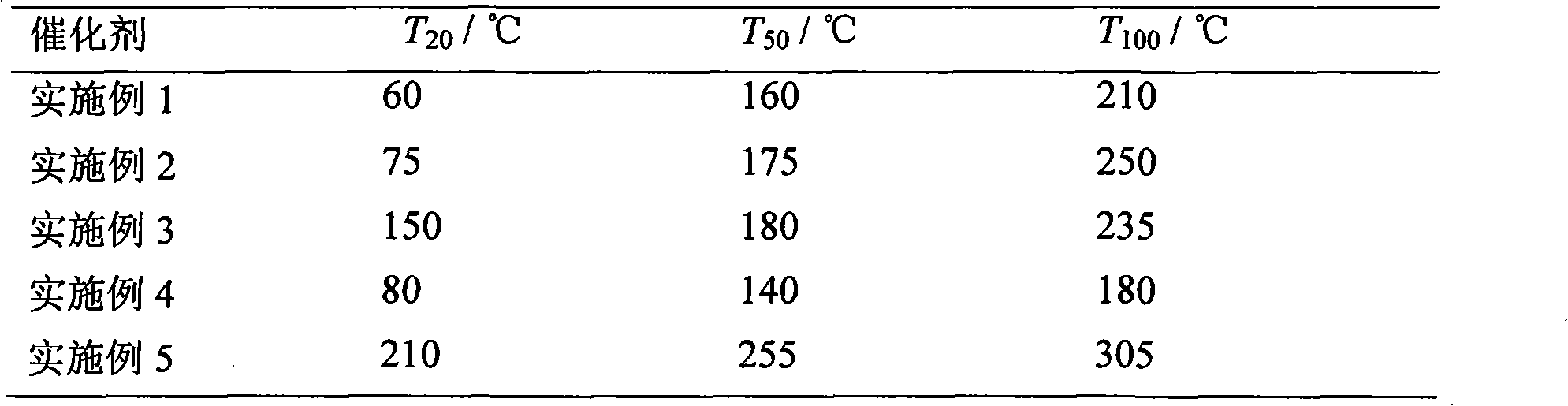

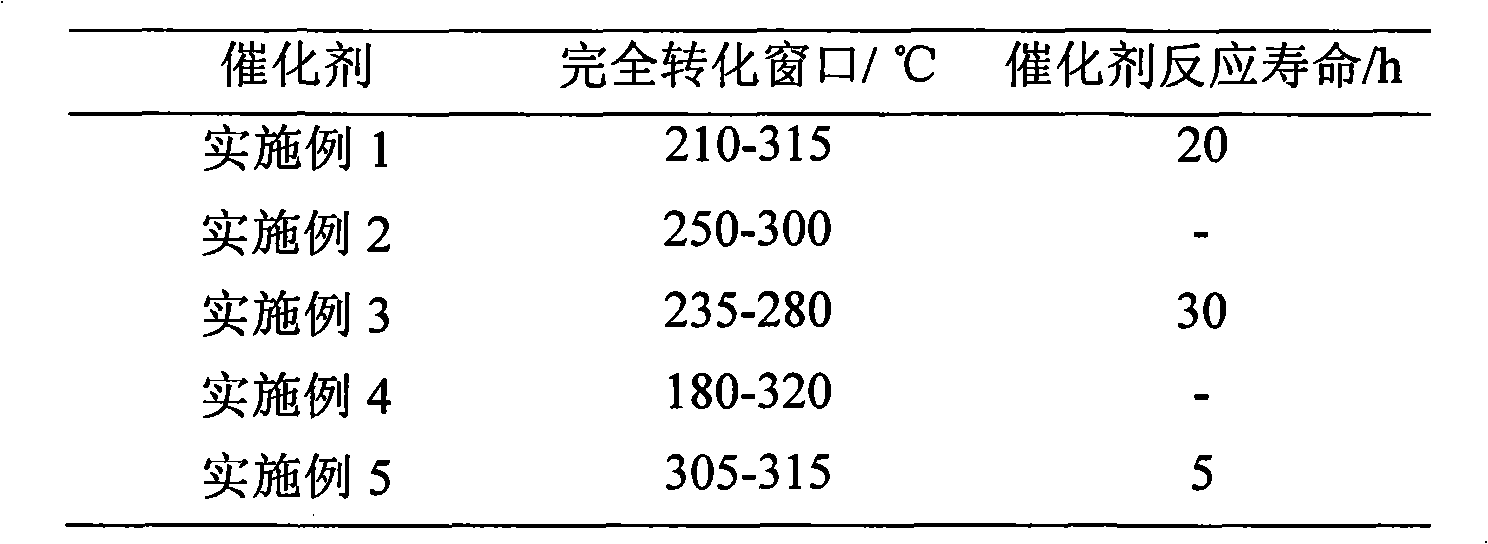

[0021] Implementation example 1:

[0022] 12g Mn(NO 3 ) 2 , 55g Al 2 o 3 , 100g deionized water, under the condition of mechanical stirring, add 5mL concentrated nitric acid, adjust the pH to 3-4, stir for 0.5-2 hours, after the slurry is stable. Under vacuum conditions, the slurry is coated on the cordierite ceramic carrier, soaked for 15-30min, and excess slurry is removed with compressed air. Then dry at room temperature for 12 hours, and calcined at 500-800°C for 2 hours to obtain the desired catalyst.

[0023] Implementation example 2:

[0024] 12g Mn(NO 3 ) 2 , 13 g H 3 o 40 PW 12 ·xH 2 O, 55g Al 2 o 3 , 100g deionized water, under the condition of mechanical stirring, add 5mL concentrated nitric acid, adjust the pH to 3-4, stir for 0.5-2 hours, after the slurry is stable. Under vacuum conditions, the slurry is coated on the cordierite ceramic carrier, soaked for 15-30min, and excess slurry is removed with compressed air. Then dry at room temperature for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com