Construction method for protecting slope of soil-nail wall and special equipment for protecting slope of soil-nail wall

A construction method and technology of special equipment, applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve the problems of equipment not working, low production efficiency, high labor intensity, etc., and achieve improved work efficiency, low site requirements, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

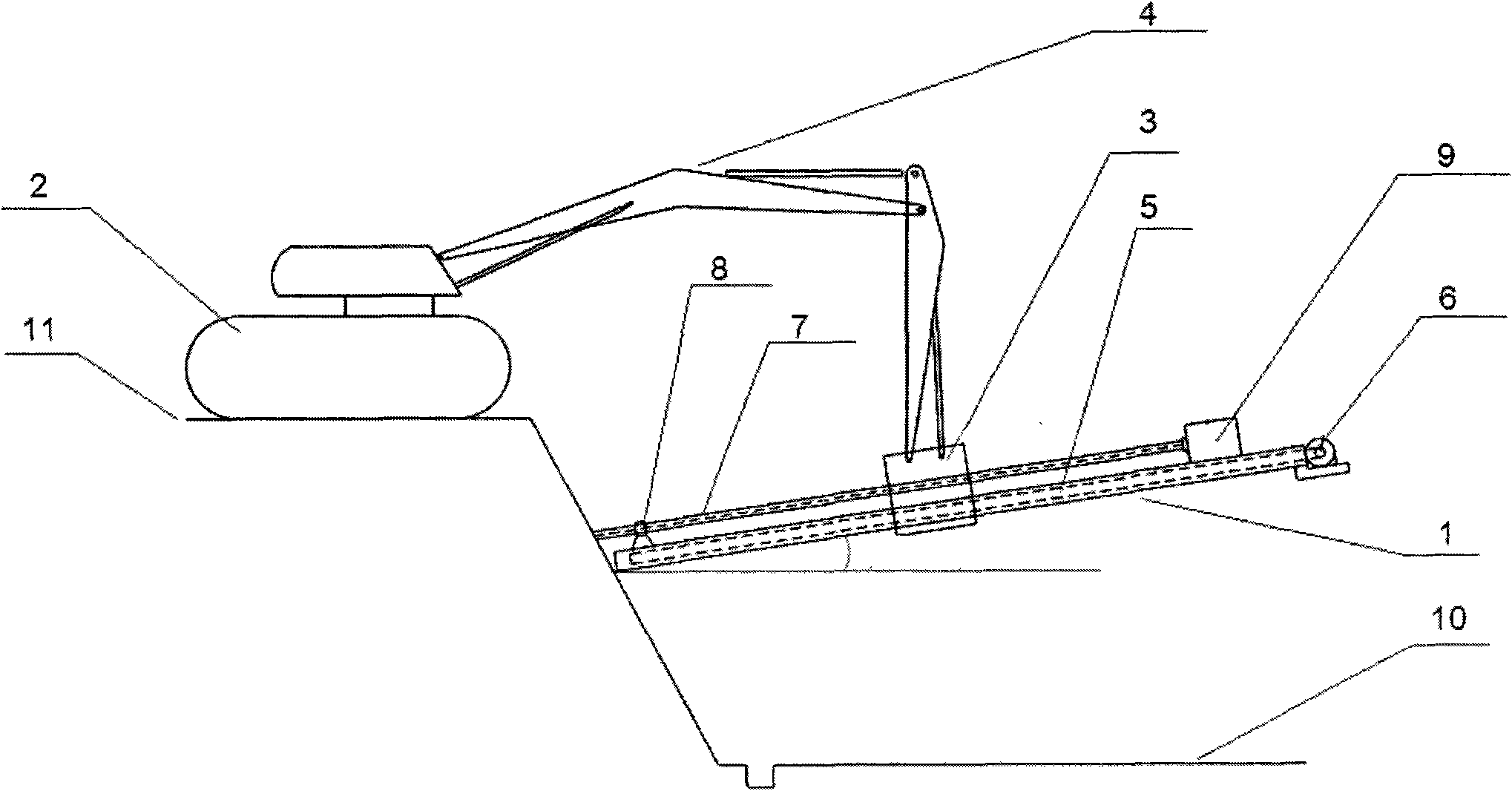

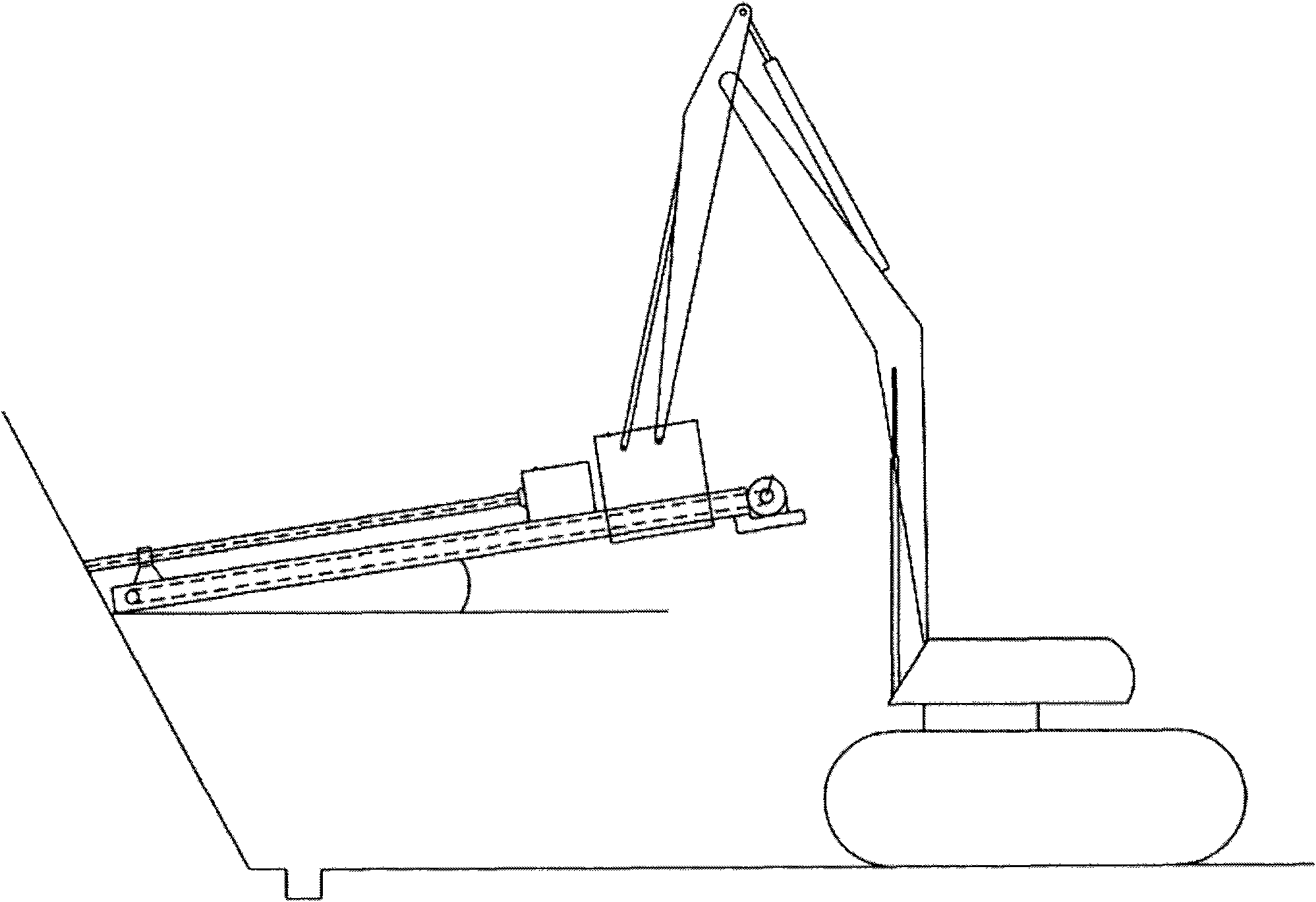

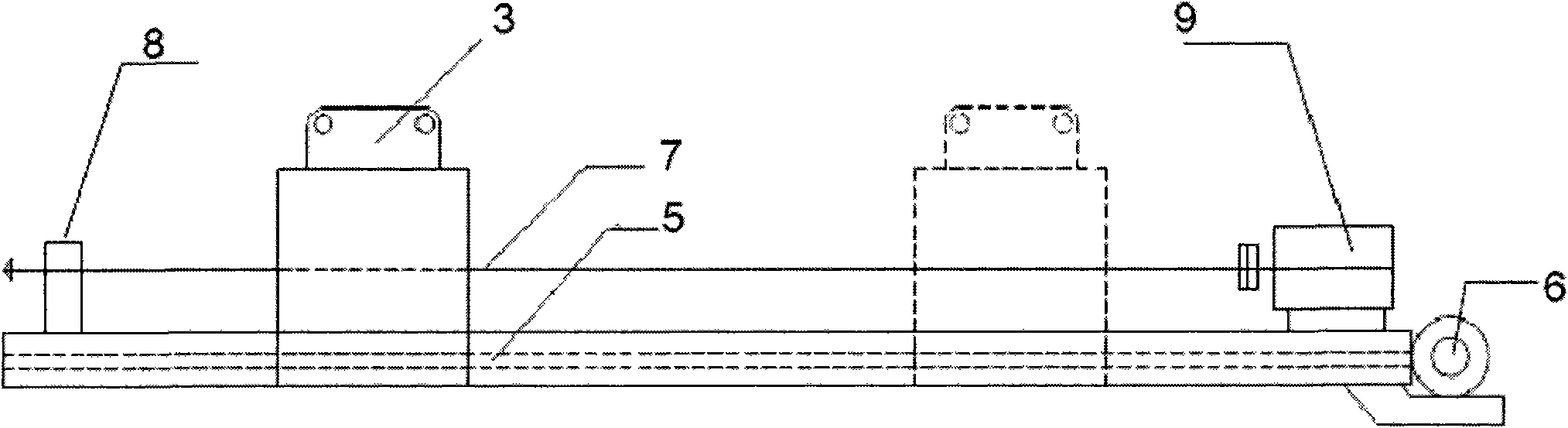

[0023] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments. As shown in the figure, it includes: bolter 1, excavator type platform 2, connecting support 3, movable arm 4, frame 5, transmission motor 6, drill rod or anchor rod 7, positioning frame 8, power unit 9, base Pit 10, upward bevel 11.

[0024] This construction method is to drill, drive into the bolter 1 and connect the excavator or excavator type platform 2 through the connecting support 3, and the machine can operate as long as the excavating machine can pass through. When there is no operating scene in the lower part of the foundation pit at the construction site, the equipment can be parked on the upward slope 11 by adjusting the movable arm 4 of the excavator, and the construction can be performed from top to bottom; otherwise, the excavator can also be parked in the foundation pit 10, from below Construction upwards. The positioning frame 8 fixe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap