Testing method for packaging effect of battery cell packaging bag

A technology of battery cells and testing methods, which is applied in the direction of material analysis through observation of the influence of chemical indicators, analysis through chemical reactions of materials, and use of material absorption and weighing. It can solve the problems affecting the packaging of aluminum-plastic packaging bags. The actual judgment of the effect, the difference in the electrical performance of the battery cell, etc., to achieve the effect of improving the overall production efficiency, simple method, and reducing the overall production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

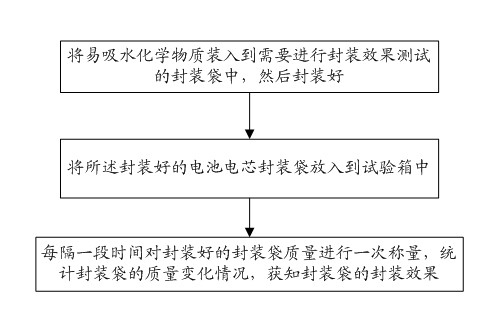

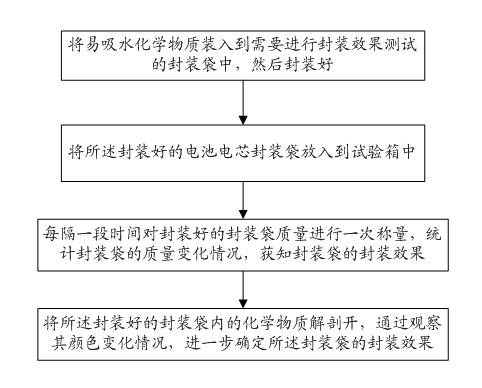

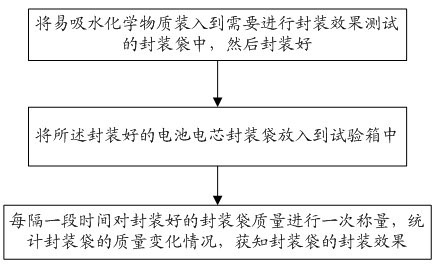

Method used

Image

Examples

Embodiment 1

[0037] In order to investigate the packaging effect of the battery cell aluminum-plastic packaging bag at different packaging widths, the following operations can be performed: weigh the quality of the double-sided sealed aluminum-plastic packaging bag as m 1 , put the chemical substance color-changing silica gel in a dry environment, and weigh the total mass as m 2 (Note, in order to achieve a more ideal test effect, it is best to keep the same quality of chemical substances loaded in the same batch of tests, or the same number of silica gel particles loaded). Then the quality of the color-changing silica gel actually packed into the aluminum-plastic packaging bag is: m 2 -m 1 .

[0038] Seal the color-changing silicone according to the standard packaging process (that is, the other side is packaged), and form an aluminum-plastic packaging bag to package the sample. Divide the sealed samples into several groups, the sample size of each group is preferably more than 32, and...

Embodiment 2

[0040] In order to investigate the packaging effect of the battery cell aluminum-plastic packaging bag at different packaging widths, the following operations can be performed: weigh the quality of the double-sided sealed aluminum-plastic packaging bag as m 1 , put the chemical substance anhydrous copper sulfate in a dry environment, and weigh the total mass as m 2 (Note, in order to achieve a more ideal test effect, it is best to keep the same quality of chemical substances loaded in the same batch of tests, or the same number of silica gel particles loaded). Then, the quality of the anhydrous copper sulfate actually packed into the aluminum-plastic packaging bag is: m 2 -m 1 .

[0041] Seal the chemical substance according to the standard packaging process (that is, the other side is packaged), and form an aluminum-plastic packaging bag to package the sample. Divide the sealed samples into several groups, each group should have more than 32 samples, and package each group...

Embodiment 3

[0043] In order to investigate the performance of aluminum-plastic packaging bags of different models or specifications (such as different thicknesses or different manufacturers), the following operations can be performed: weigh the quality of the double-sided sealed aluminum-plastic packaging bags as m 1 , put the chemical substance color-changing silica gel in a dry environment, and weigh the total mass as m 2 (Note, in order to achieve a more ideal test effect, it is best to keep the same quality of chemical substances loaded in the same batch of tests, or the same number of silica gel particles loaded). Then the quality of the color-changing silica gel actually put into the aluminum-plastic packaging bag is: m 2 -m 1 .

[0044] Seal the chemical substance according to the standard packaging process (that is, the other side is packaged), and form an aluminum-plastic packaging bag to package the sample. Divide the sealed samples into several groups, and the sample size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com