Heat pipe heat radiating system of digital light processing (DLP) projector

A technology of cooling system and projector, applied in cooling/ventilation/heating renovation, optics, instruments, etc., can solve problems such as affecting the contrast, color and service life of the projector, reducing the imaging quality of the projected image, and thermal degradation of the projector, etc. Achieve the effect of reducing temperature, good sealing and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

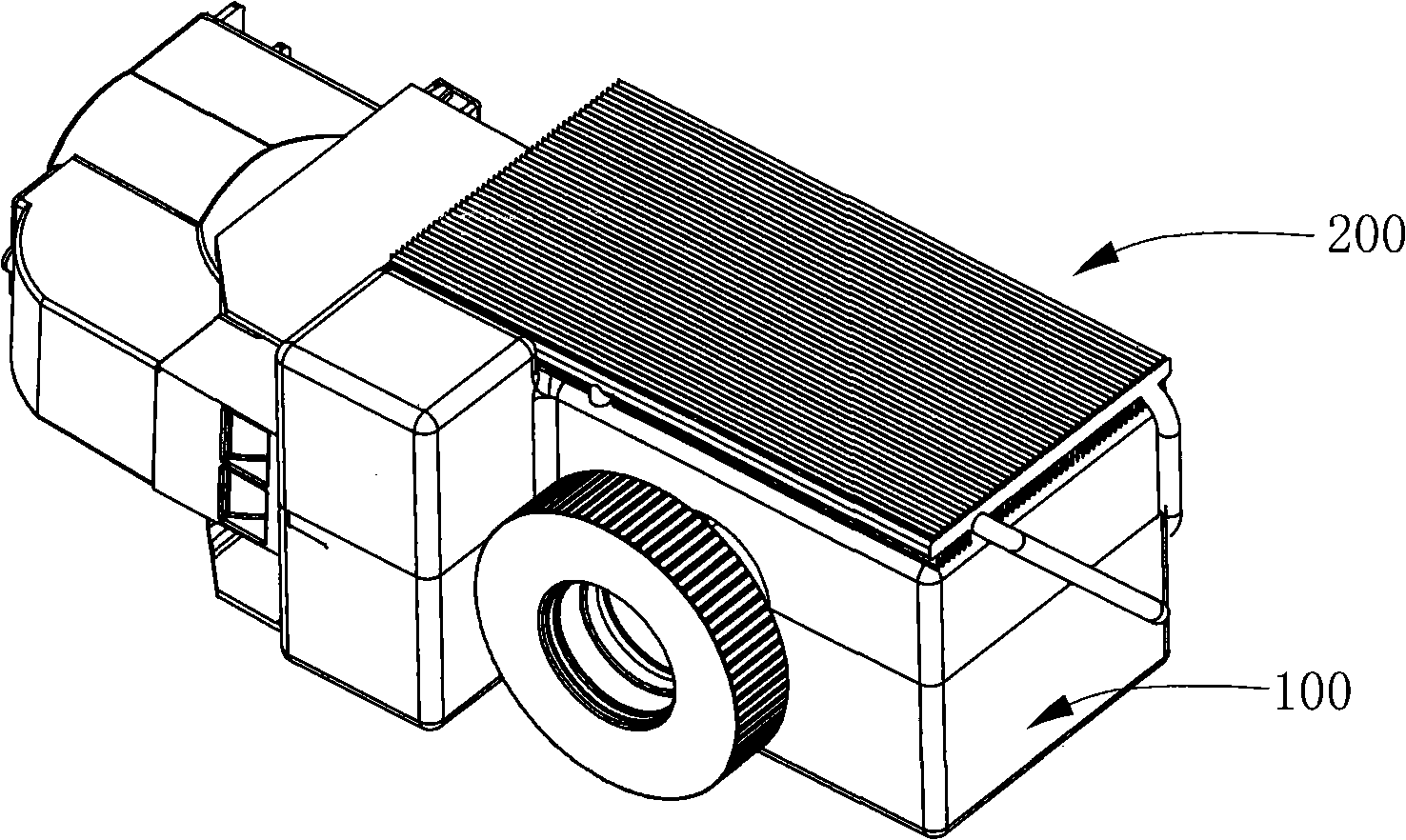

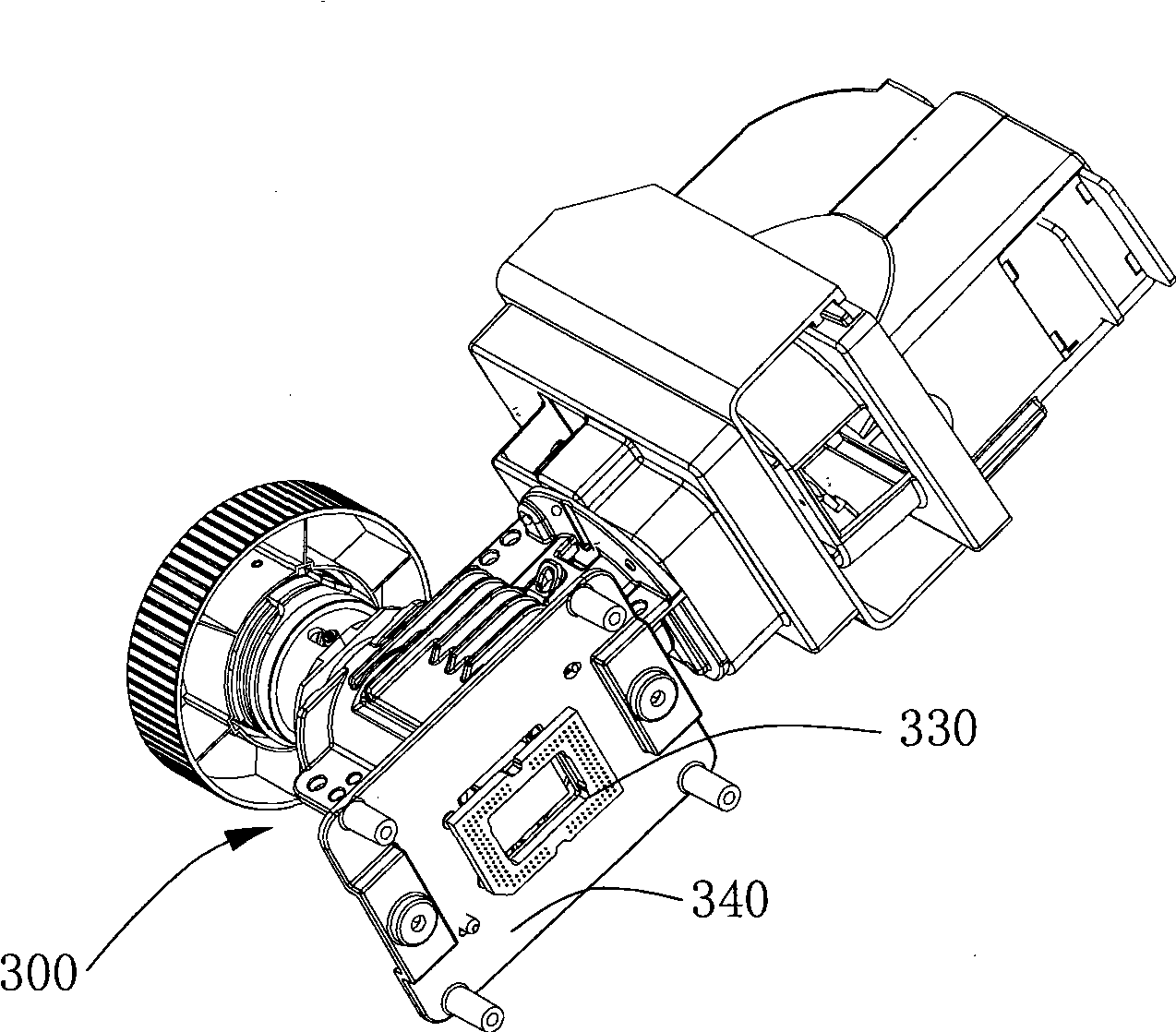

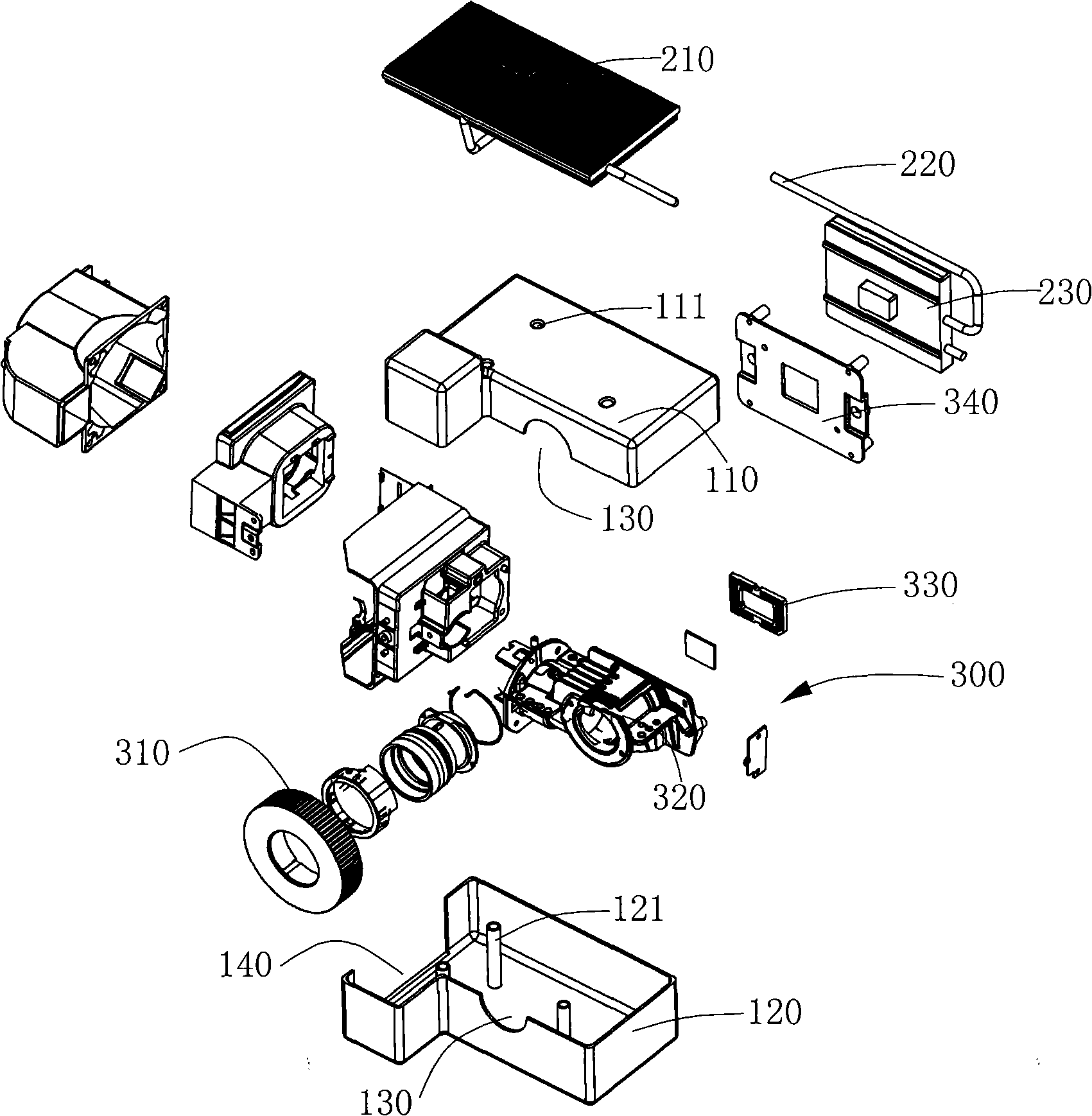

[0022] see Figure 1-7 , a DLP projector heat pipe cooling system includes a cover 100 , a cooling device 200 and an optical body 300 . The cover 100 accommodates the optical body 300 and conducts and dissipates heat generated by the optical body 300 through the cooling device 200 .

[0023] The cover body 100 is hollow inside, used for accommodating and sealing the optical main body 300 , and includes a top cover 110 and a bottom cover 120 . The top cover 110 and the bottom cover 120 are respectively provided with arc-shaped notches 130 and square notches 140 . The top cover 110 is provided with screw holes 111 , and the bottom cover is provided with fixing posts 121 corresponding to the screw holes 111 . Screws pass through the screw holes 111 and are fixed to the fixing posts 121 , so that the top cover 110 and the bottom cover 120 are closed. The top cover 110 merges with the arc-shaped notch 130 in the bottom cover 120 to form a circular notch, which is adapted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com