Device for maintaining stability of polarization direction and energy of optical signals with low repetition frequency and short pulse

A technology of repetition frequency and polarization direction, applied in lasers, laser parts, electrical components, etc., can solve the problems of difficulty in real-time compensation of optical pulse signals, difficulty in energy collection, and low repetition frequency, and achieves simple structure and easy system integration. , the effect of reducing the measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

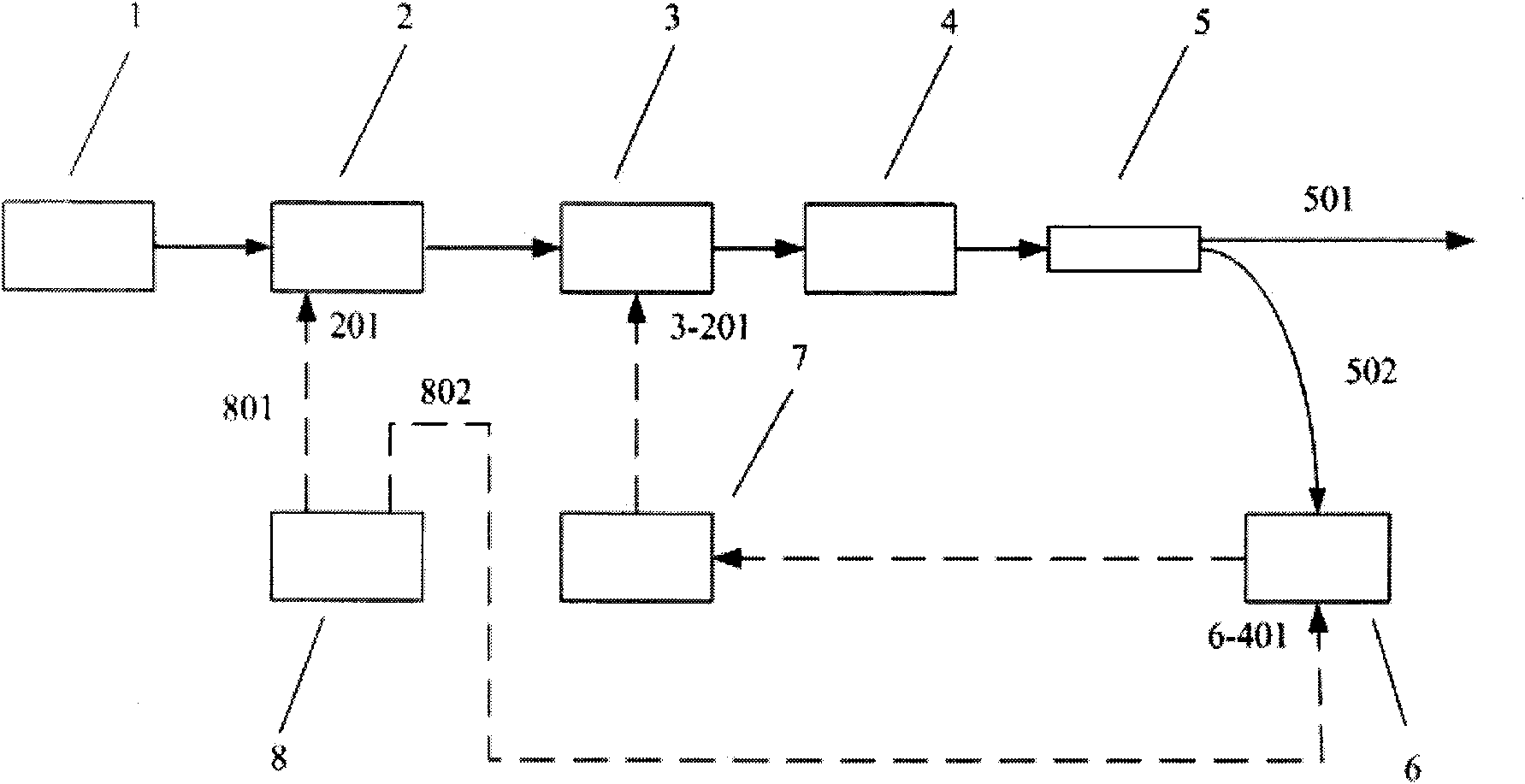

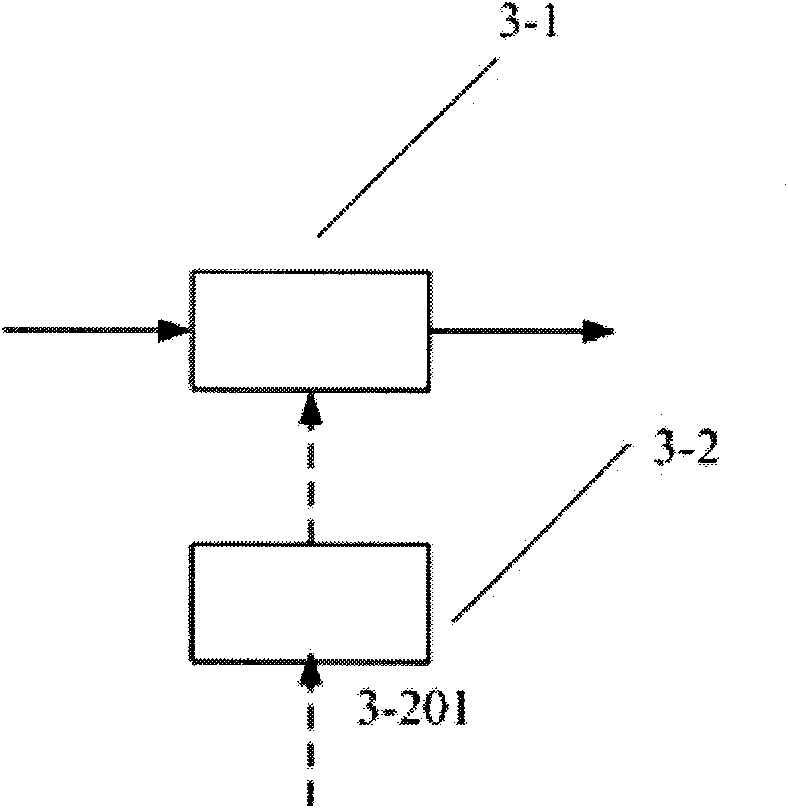

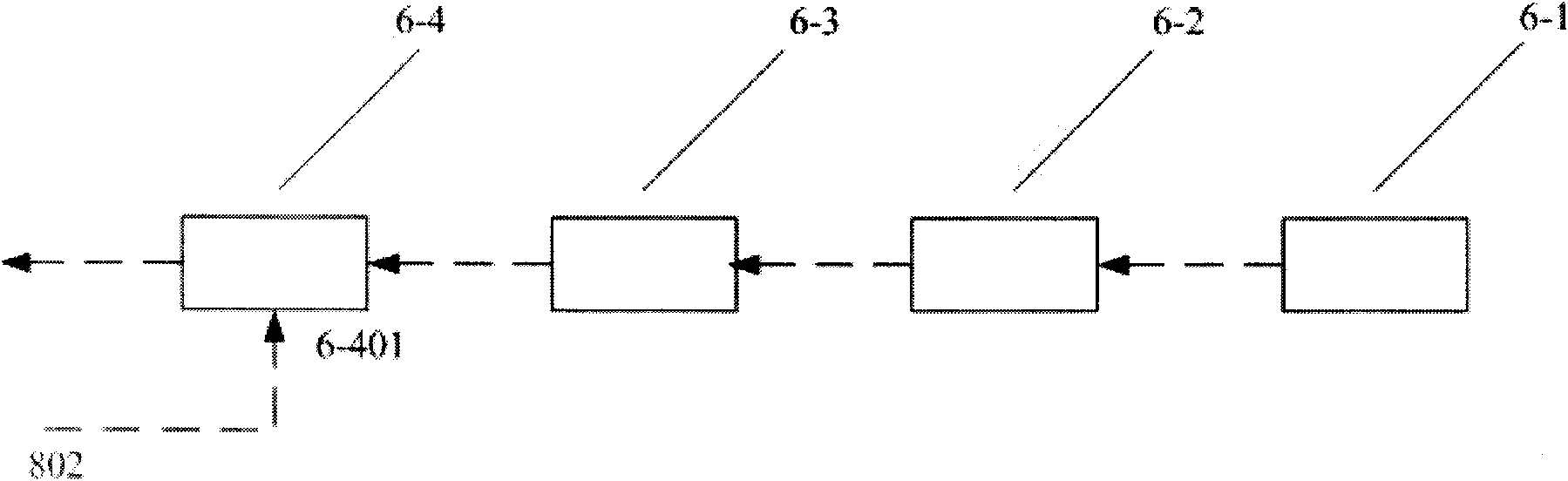

[0025] see first figure 1 , figure 2 with image 3 , figure 1 It is a structural schematic diagram of the device for maintaining the polarization direction and energy stability of low repetition frequency short pulse optical signals according to the present invention, figure 2 is a structural schematic diagram of the feedback unit of the present invention, image 3 It is a structural schematic diagram of the control unit of the present invention. It can be seen from the figure that the device for maintaining the polarization direction and energy stability of low repetition frequency short pulse optical signals in the present invention consists of a continuous fiber laser 1, an optical pulse generator 2, a polarization control unit 3, a polarizer 4, a fiber beam splitter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com