Electrode shell of large submerged arc furnace

A submerged arc furnace and electrode shell technology, which is applied to electric heating devices, electrical components, heating through discharge, etc., can solve the problems of high cost, many ribs, and many iron materials, so as to increase the ability to withstand current and reduce the quantity and width, increasing the effect of inscribed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The large-scale submerged arc furnace electrode shell of the present invention will be further described below in conjunction with the accompanying drawings.

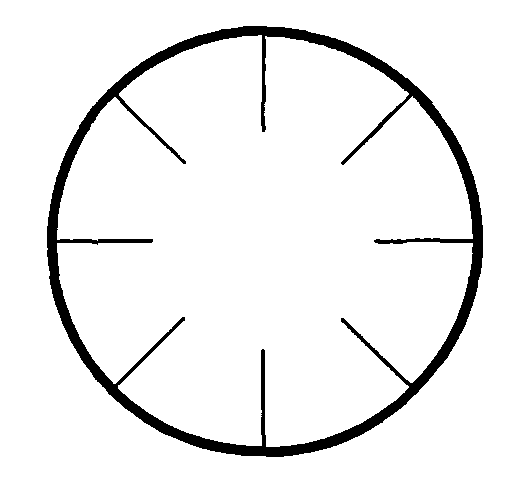

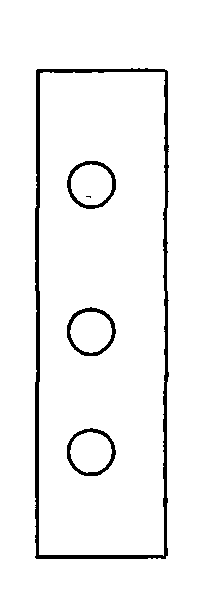

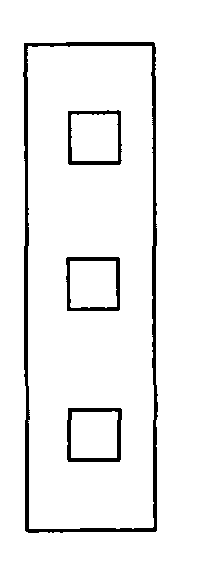

[0016] see Figure 4 , Figure 5 , The large-scale submerged arc furnace electrode shell of the present invention includes successively connected cylinder sections, the cylinder section comprises a cylindrical shell 1, the shell 1 is a deoxidized low-carbon steel plate with a thickness of 3mm, and the diameter of the shell 1 is 1.4 meters. The inner side of the housing 1 is longitudinally provided with four ribs 3 arranged at equal distances. The ribs 3 are formed by overlapping and welding two steel plates. There are several circular holes 4 with a diameter of 20mm between the two steel plates. The circular holes Increase the internal connection strength, contact area and conductive effect between the electrode shell and the electrode paste; the upper ends of the two steel plates are provided with bifurcations,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com