Mixer settler for three-phase extraction

A technology of mixing clarifier and clarifier, which can be used in liquid solution solvent extraction and other directions, and can solve problems such as phase flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

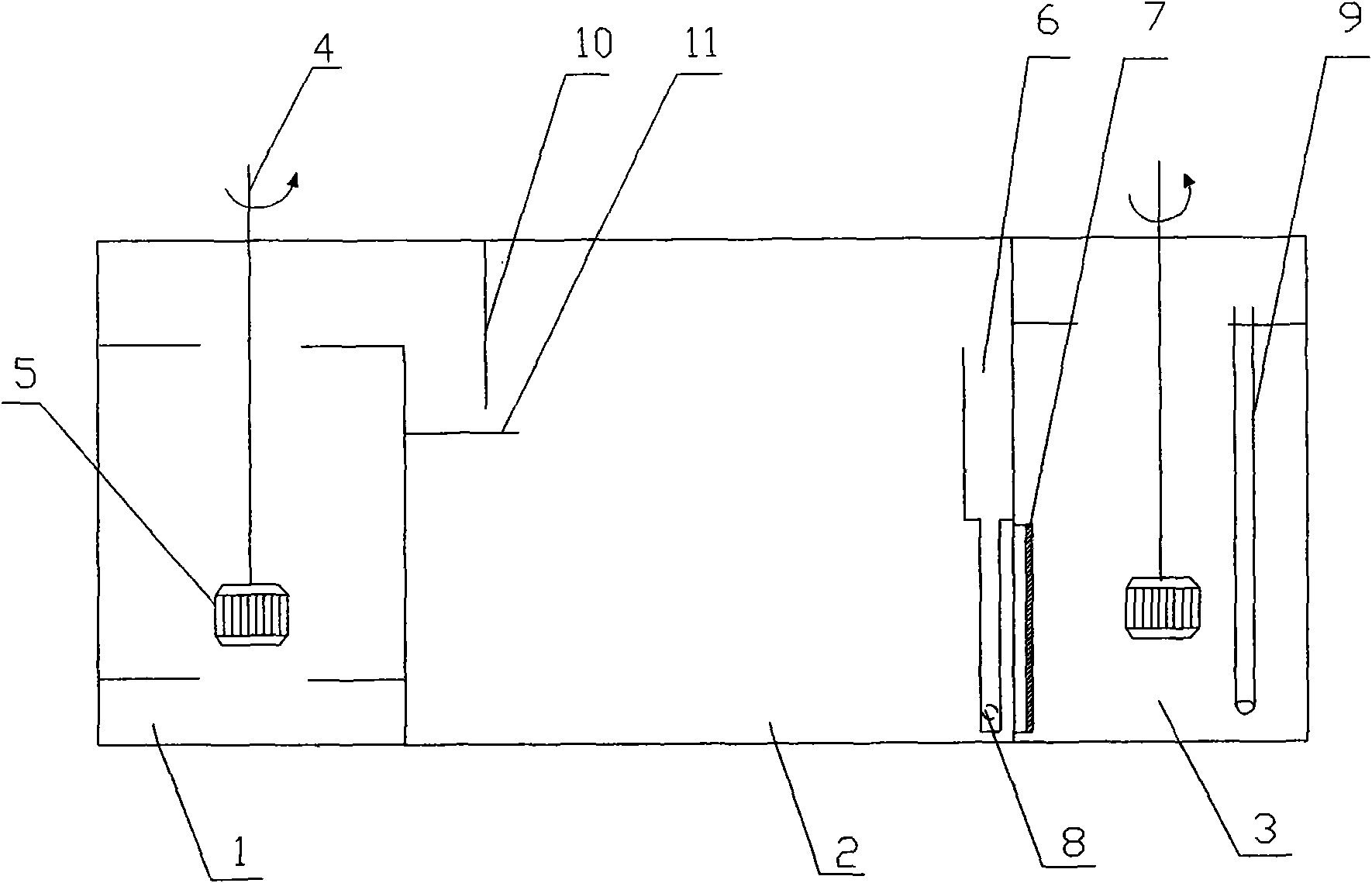

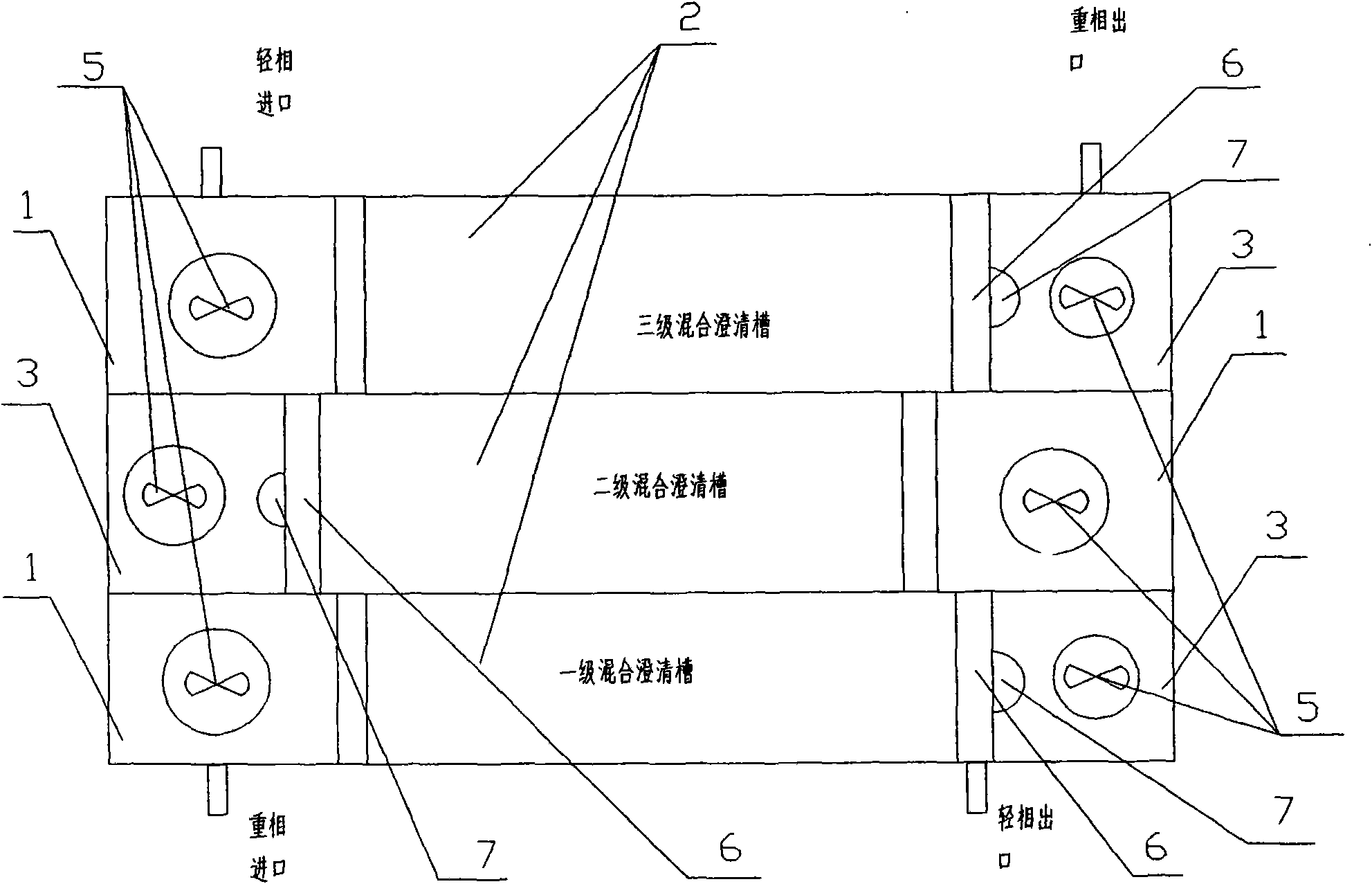

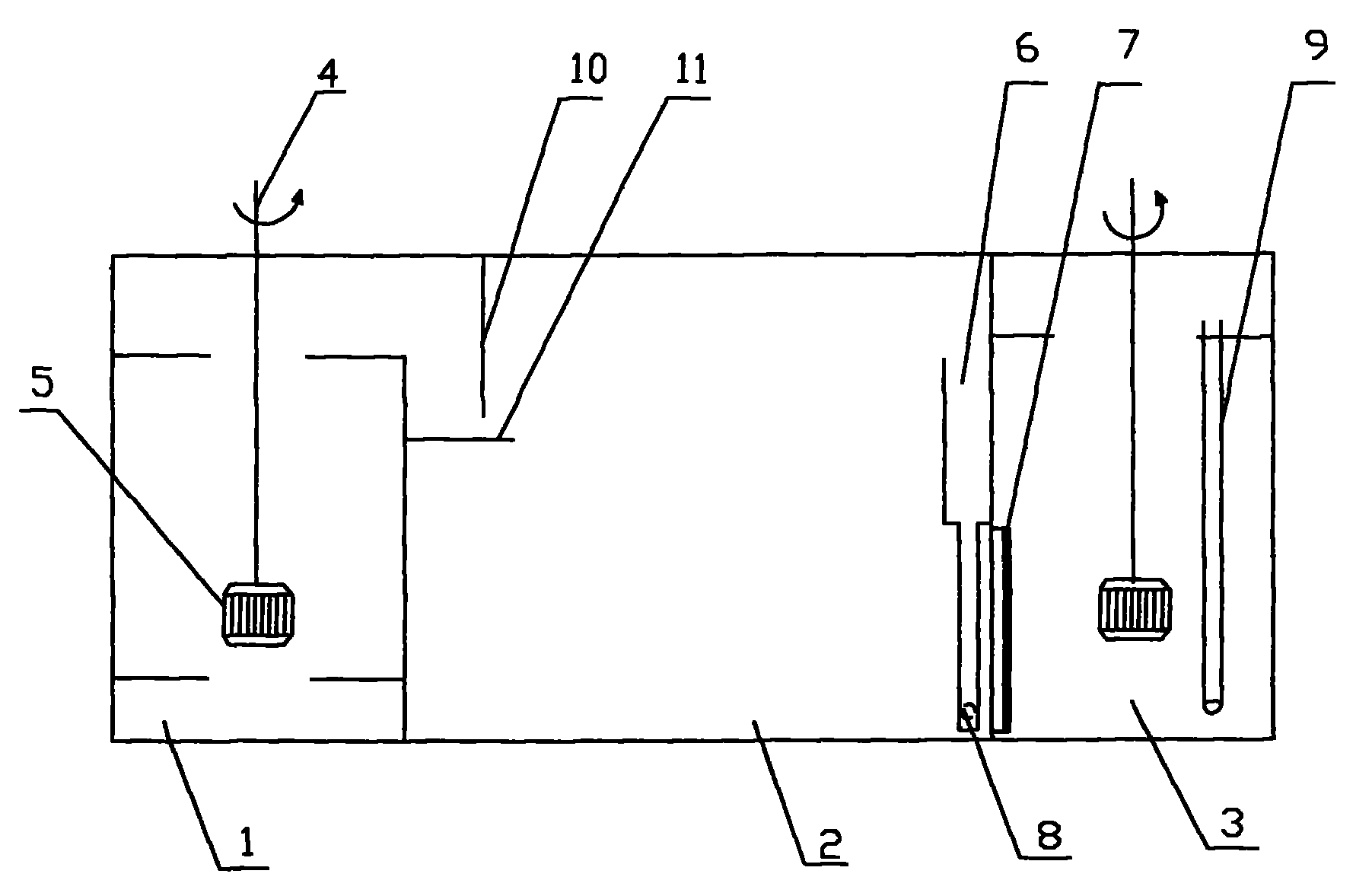

[0050] See figure 1 and figure 2 . The mixing and settling tank for three-phase extraction is divided into a mixing and settling tank with the same structure by two partitions, a mixing and settling tank, a secondary mixing and settling tank and a third mixing and settling tank; in the above mixing and settling tank All include three-phase mixing chamber 1, clarification chamber 2, middle and lower phase mixing chamber 3, stirring motor 4, self-priming stirring blade 5, light phase separation chamber 6, meniscus baffle 7, light phase outlet pipe 8 , heavy phase outlet pipe 9, baffle baffle 10 and transverse partition 11, etc.

[0051] There are three-phase mixing chamber 1, clarification chamber 2 and middle and lower phase mixing chamber 3 in the primary mixing and settling tank, secondary mixing and settling tank and tertiary mixing and settling tank; among them, the clarification chamber 2 is located between the three-phase mixing chamber 1 and the middle Between the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com