Preparation method of porous structured active carbon

A technology of hierarchical pores and activated carbon, which is applied to the preparation of a hierarchical porous carbon material and activated carbon with a natural template and an activator, to achieve reduced production costs, good rate performance, and reduced dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

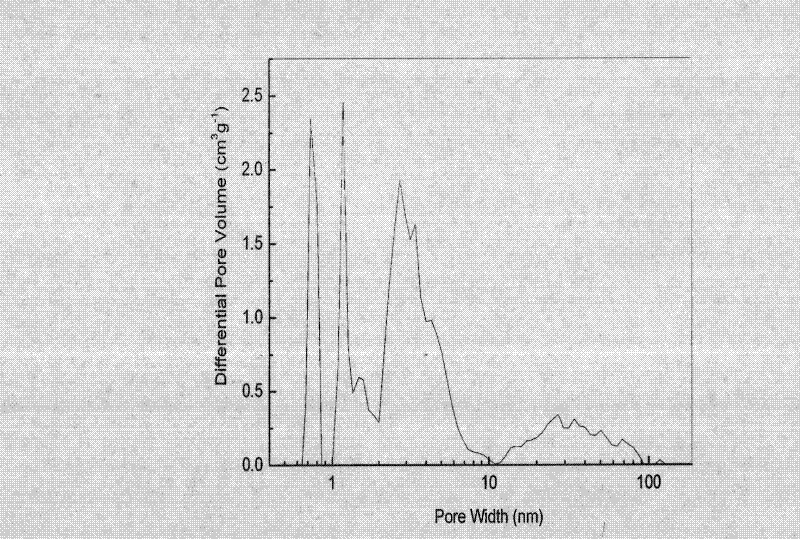

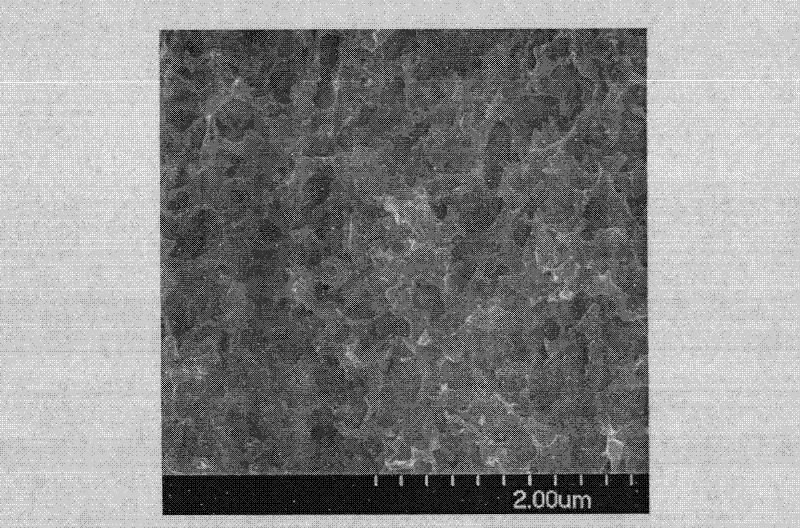

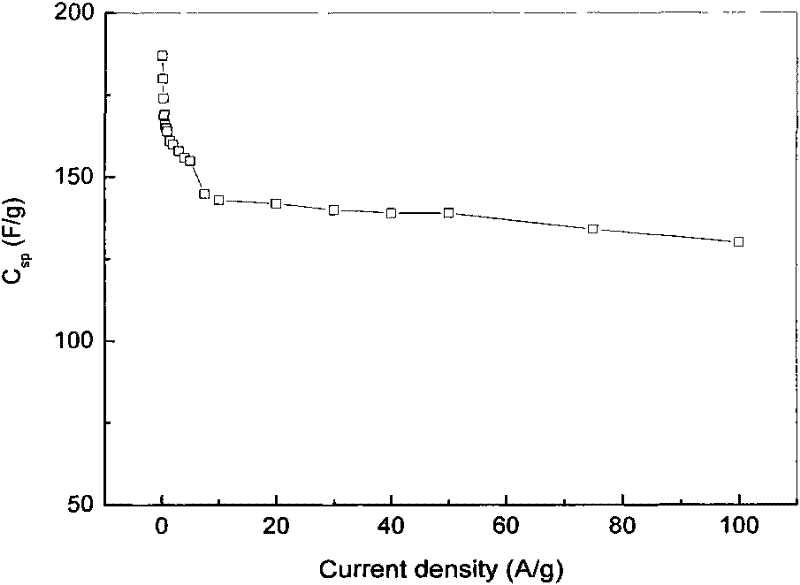

[0017] Example 1: Put 100 g of dried pork bone into a tube electric furnace, blow nitrogen into it, and pre-carbonize at 450° C. for 2 hours. After the pre-carbonized pig bone is pulverized into powder, it is mixed with 100g KOH evenly. Then put it into a tubular electric furnace, feed nitrogen, raise the temperature to 850°C at a rate of 2.5°C / min, and activate for 1h. After cooling, the product was taken out, washed with 2mol / L hydrochloric acid solution, washed with water until neutral, and dried to obtain activated carbon with a hierarchical porous structure. The specific surface area of activated carbon is 2157m 2 / g, the pore volume is 2.26cm 3 / g, the pores are three-dimensionally distributed, the average pore diameter is 4.18nm, and the micropore volume is about 0.64cm 3 / g, mesopore volume is about 1.62cm 3 / g. The pore distribution and SEM results are shown in figure 1 , figure 2 . Depend on figure 1 It can be seen that the pore size is mainly distributed...

Embodiment 2

[0020] Example 2. Put 100 g of dried bovine bone into a horizontal tube electric furnace, feed nitrogen gas and pre-carbonize at 500° C. for 1 hour. After the pre-carbonized bovine bone is pulverized into powder, it is mixed evenly with 200g KOH. Put it into a horizontal tube electric furnace again, blow in nitrogen, raise the temperature to 950°C at a rate of 2.5°C / min, and activate for 0.5h. After cooling, take it out, wash it with 1mol / L hydrochloric acid solution, wash it with water until neutral, and dry it. The specific surface area of the product is 2152m 2 / g, the pore volume is 1.23cm 3 / g, its pores are three-dimensionally distributed, with an average pore diameter of 2.18nm.

Embodiment 3

[0021] Example 3. Put 100 g of dried pork bone into a horizontal tube electric furnace, feed nitrogen gas and pre-carbonize at 450° C. for 3 hours. After the pre-carbonized animal bone is pulverized into powder, it is mixed evenly with 50g KOH. Put it into a horizontal tube electric furnace again, blow in nitrogen, raise the temperature to 650°C at a rate of 2.5°C / min, and activate for 1h. After cooling, take it out, wash it with hydrochloric acid solution, wash it with water until neutral, and dry it. The specific surface area of the product is 703m 2 / g, the pore volume is 0.57cm 3 / g, its pores are three-dimensionally distributed, with an average pore diameter of 3.25nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com