Preparation method of calcium-based carbon dioxide adsorbent

A carbon dioxide and adsorbent technology, which is applied in the field of gas enrichment, separation and purification, can solve the problem of high doping cost, achieve large adsorption capacity, reduce losses, and benefit adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

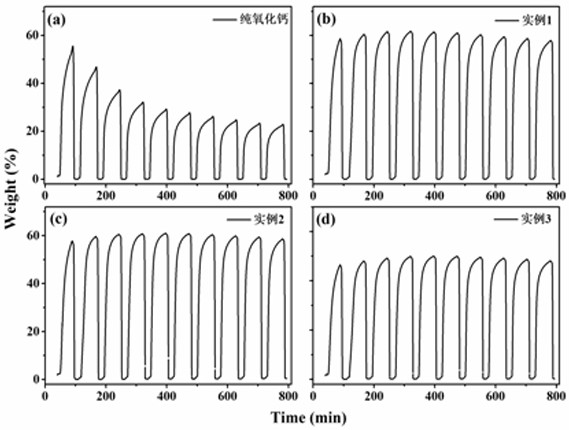

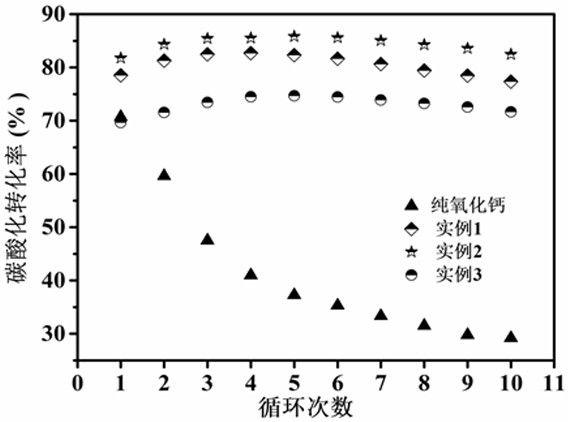

Embodiment 1

[0033] Mix calcium nitrate tetrahydrate and citric acid monohydrate in deionized water at a mass ratio of 1:1.1, and stir for 6 hours in an oil bath at 85°C; add metakaolin to the mixed solution to control the quality of metakaolin and calcium oxide The ratio is 0.5:9.5, continuously stirred in an oil bath at 85°C for 3h; the obtained mixed solution was left to stand at room temperature for 18h; the mixed solution after standing was slowly stirred at 85°C until a wet gel was formed, and the stirring rate was controlled The temperature was 90 rpm; the wet gel was dried in an oven at 105 °C for 24 h; the obtained dry gel was ground and calcined in a muffle furnace at 850 °C for 3 h, and the heating rate was controlled at 3 °C / min. A modified calcium-based carbon dioxide adsorbent is prepared.

Embodiment 2

[0035] Mix calcium nitrate tetrahydrate and citric acid monohydrate in deionized water at a mass ratio of 1:1.05, and stir for 5.5 hours in an oil bath at 85°C; add metakaolin to the mixed solution to control the quality of metakaolin and calcium oxide. The mass ratio is 1:9, stirring continuously for 3.5h in an oil bath at 85°C; the obtained mixed solution is left to stand at room temperature for 16h; the mixed solution after standing is stirred slowly at 85°C until a wet gel is formed, controlled The stirring rate was 100 rpm; the wet gel was dried in an oven at 105 °C for 22 h; the obtained dry gel was ground and calcined in a muffle furnace at 850 °C for 3 h, and the heating rate was controlled at 3 °C / min. A modified calcium-based carbon dioxide adsorbent is prepared.

Embodiment 3

[0037] Mix calcium nitrate tetrahydrate and citric acid monohydrate in deionized water at a mass ratio of 1:1, and stir for 5 hours in an oil bath at 85°C; add metakaolin to the mixed solution to control the quality of metakaolin and calcium oxide The ratio is 1.5:8.5, continuously stirred in an oil bath at 85°C for 4h; the obtained mixed solution was left to stand at room temperature for 15h; the mixed solution after standing was slowly stirred at 85°C until a wet gel was formed, and the stirring rate was controlled The temperature was 110 rpm; the wet gel was dried in an oven at 105 °C for 20 h; the obtained dry gel was ground and calcined in a muffle furnace at 850 °C for 3 h, and the heating rate was controlled at 3 °C / min. A modified calcium-based carbon dioxide adsorbent is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com